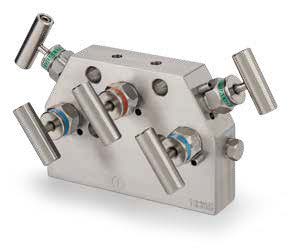

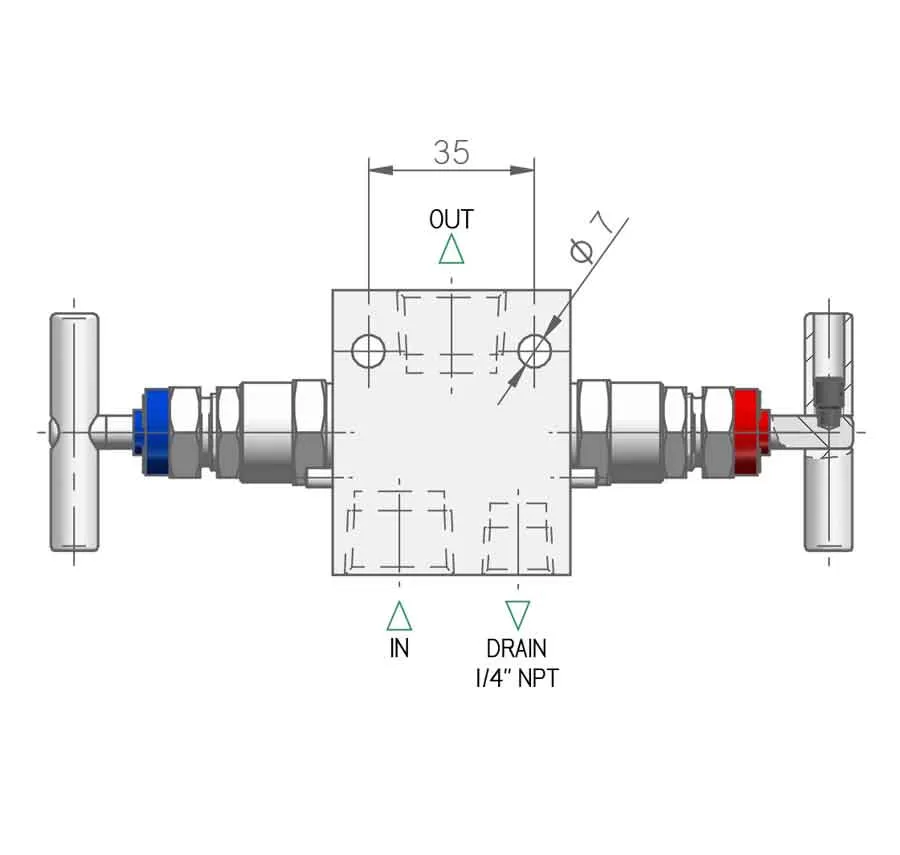

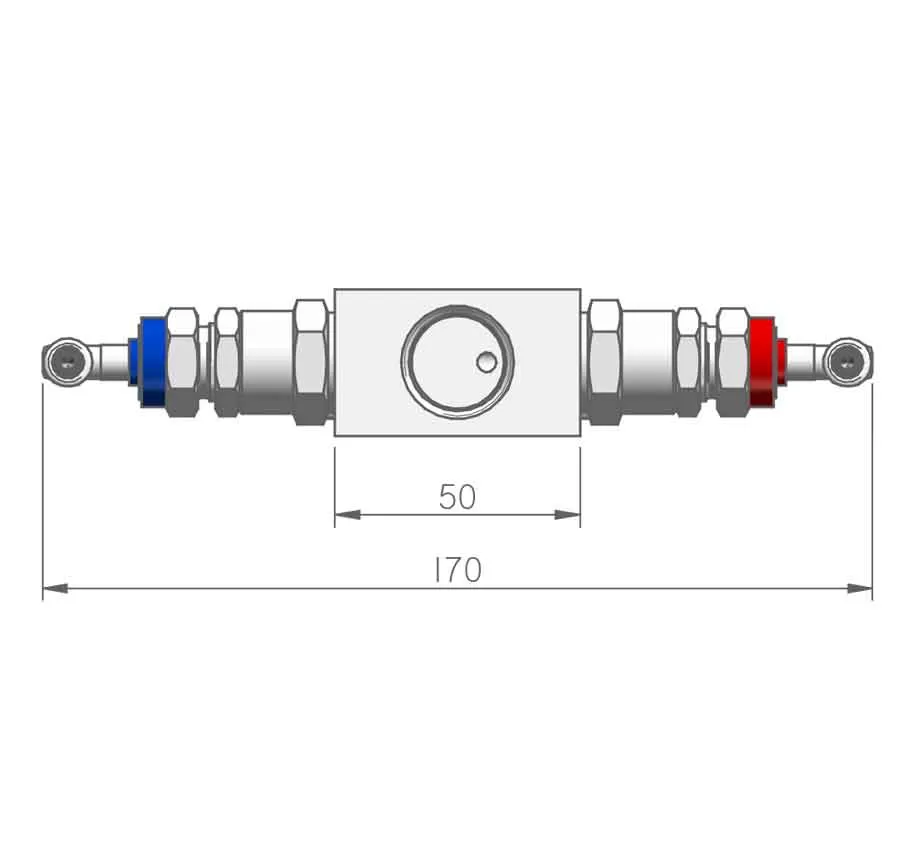

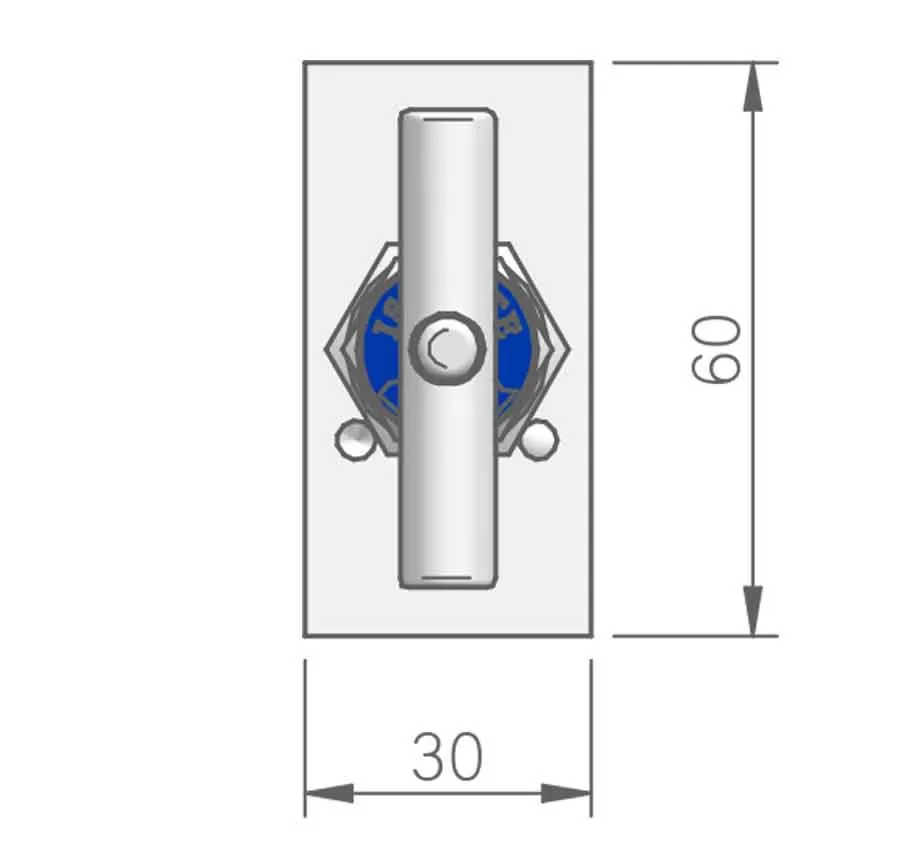

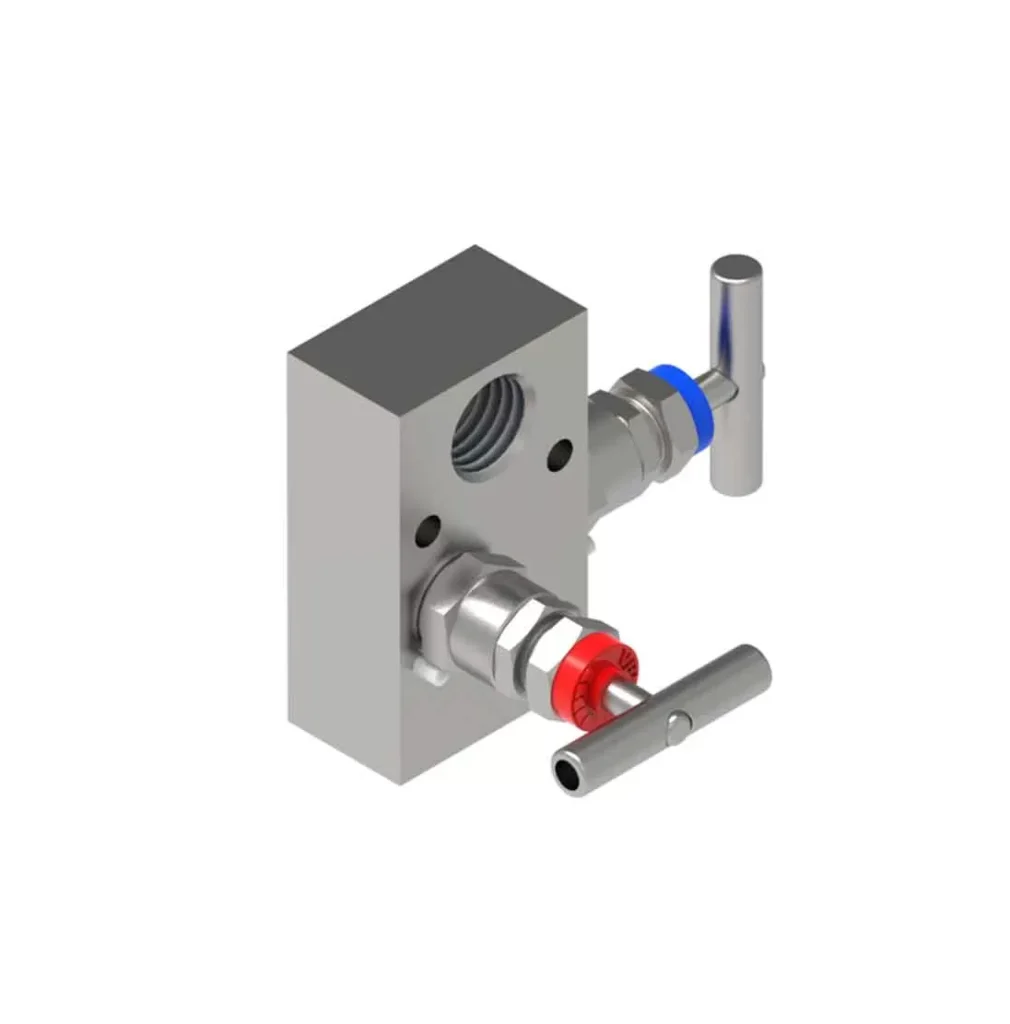

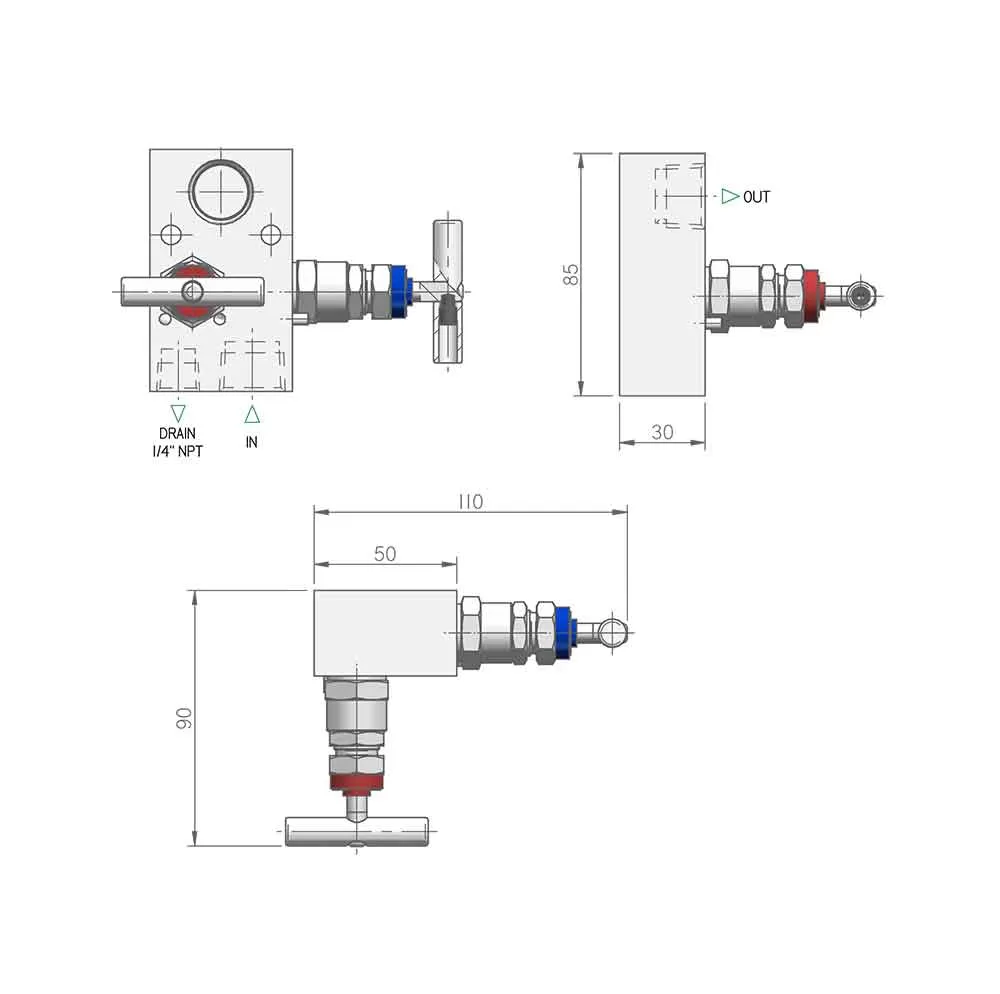

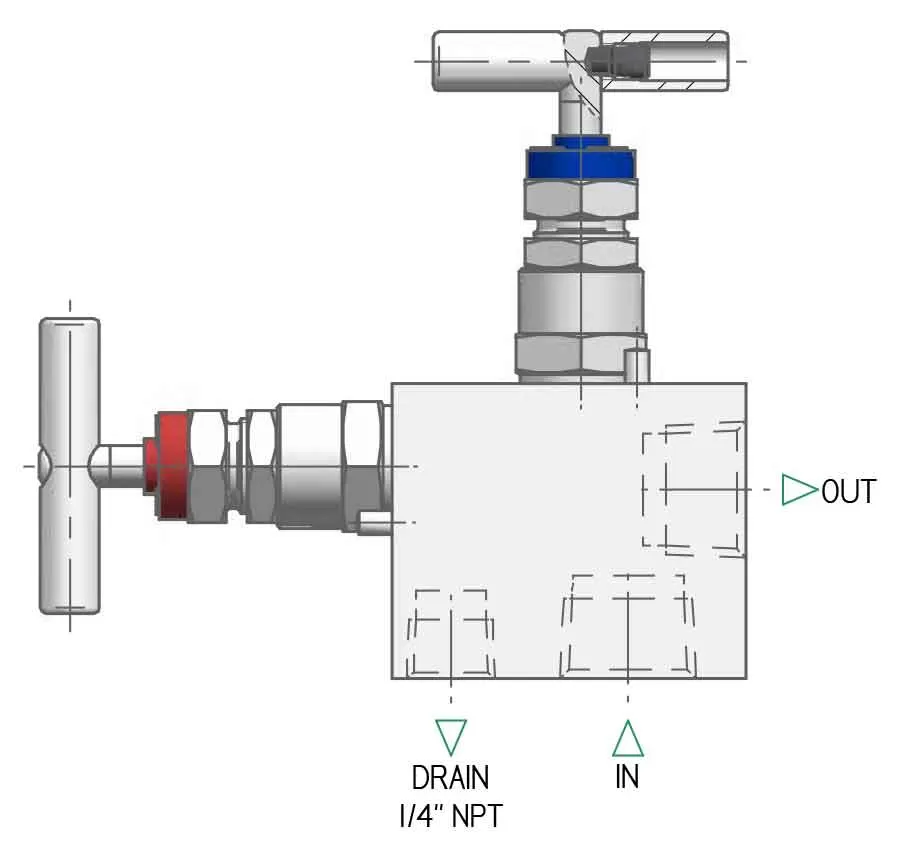

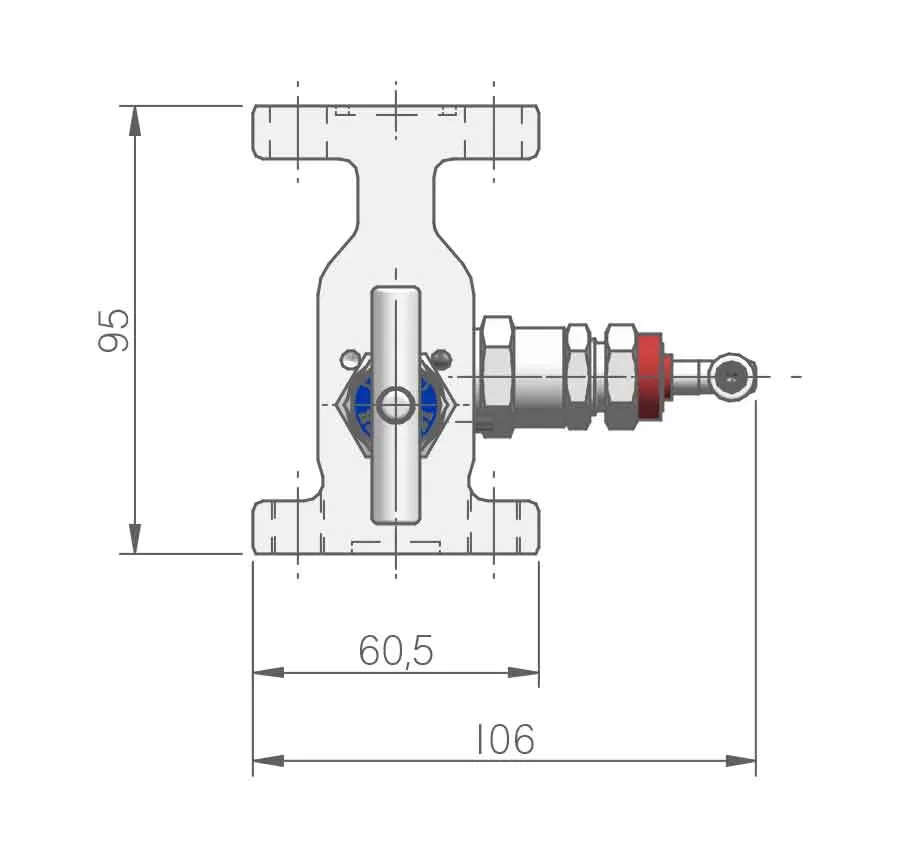

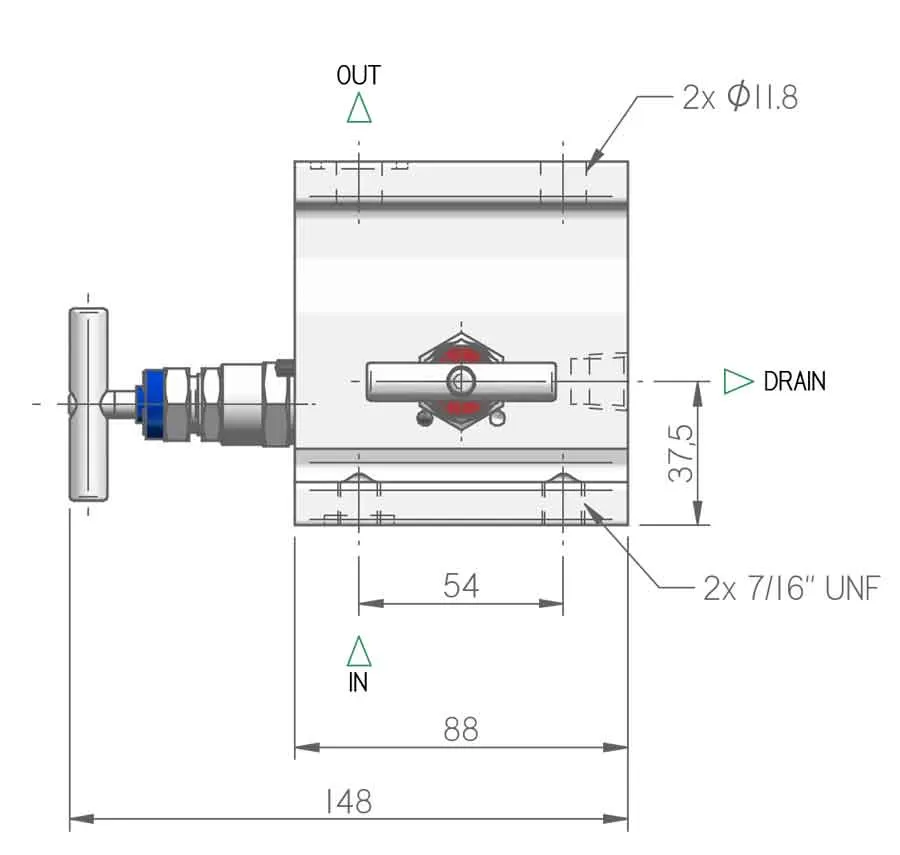

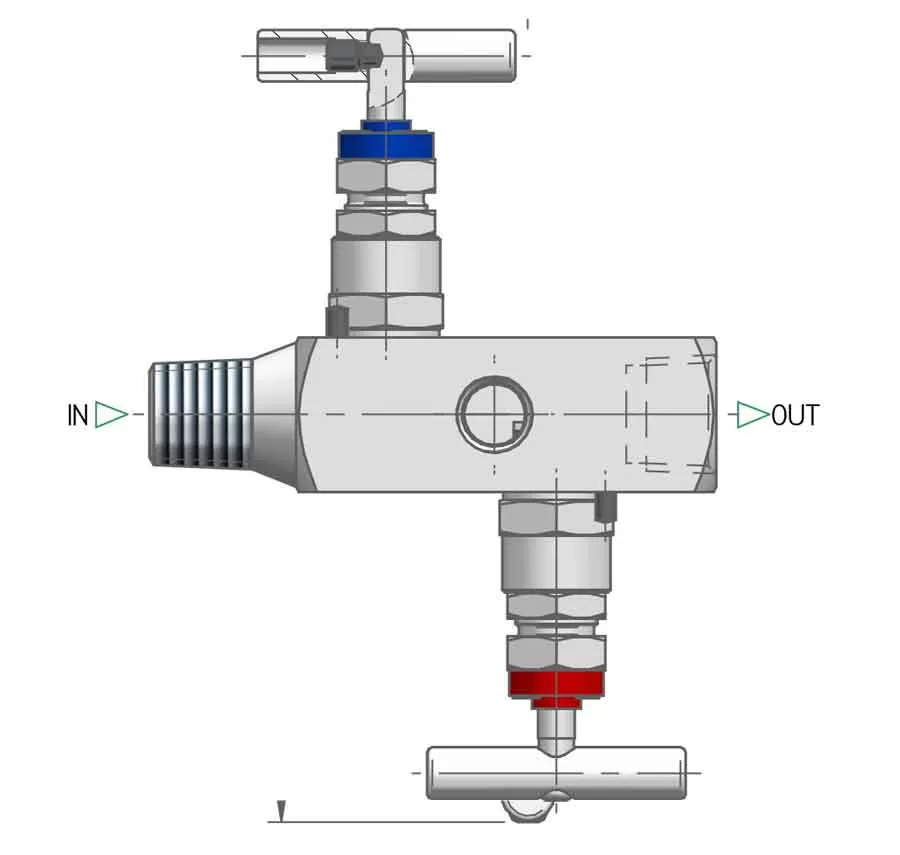

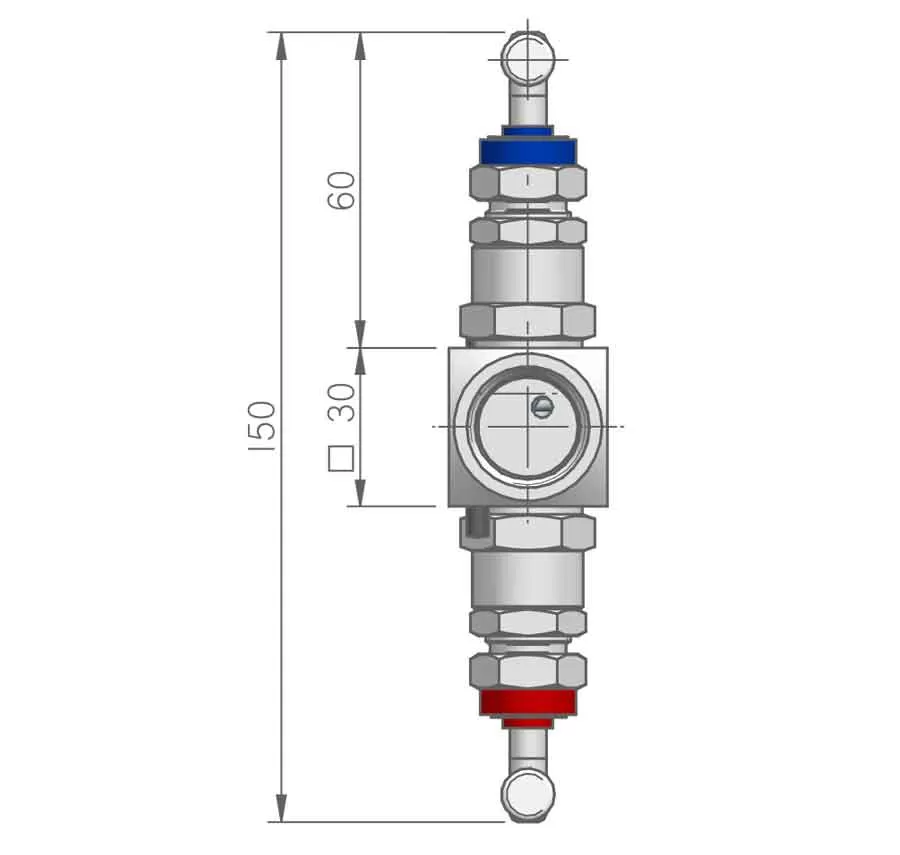

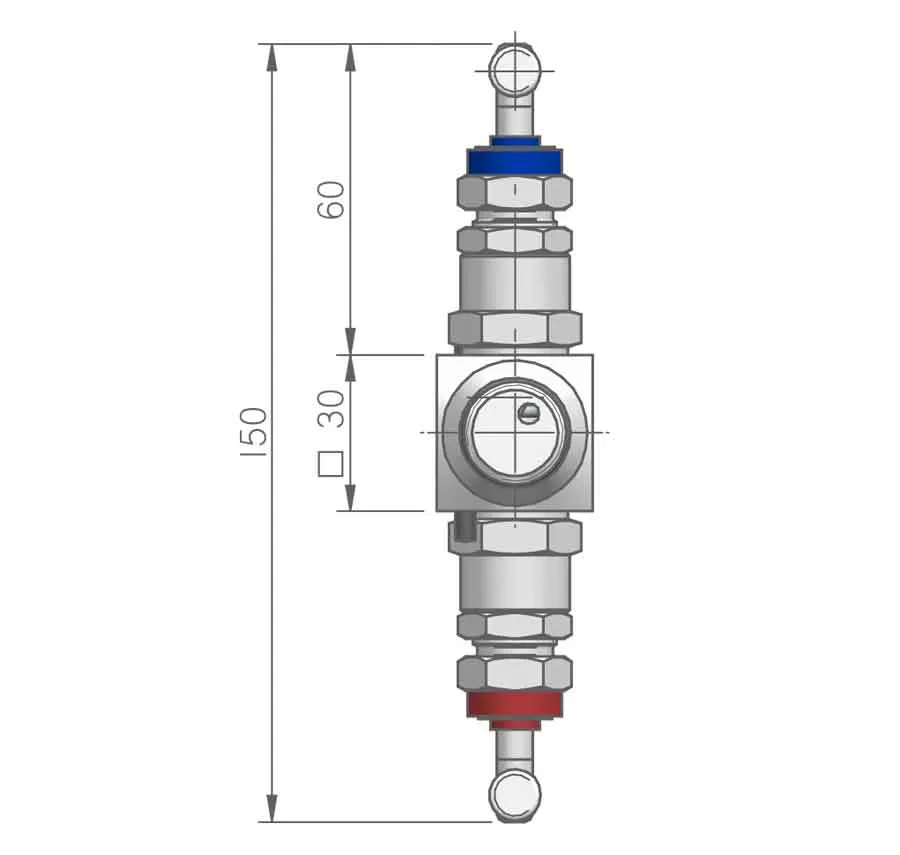

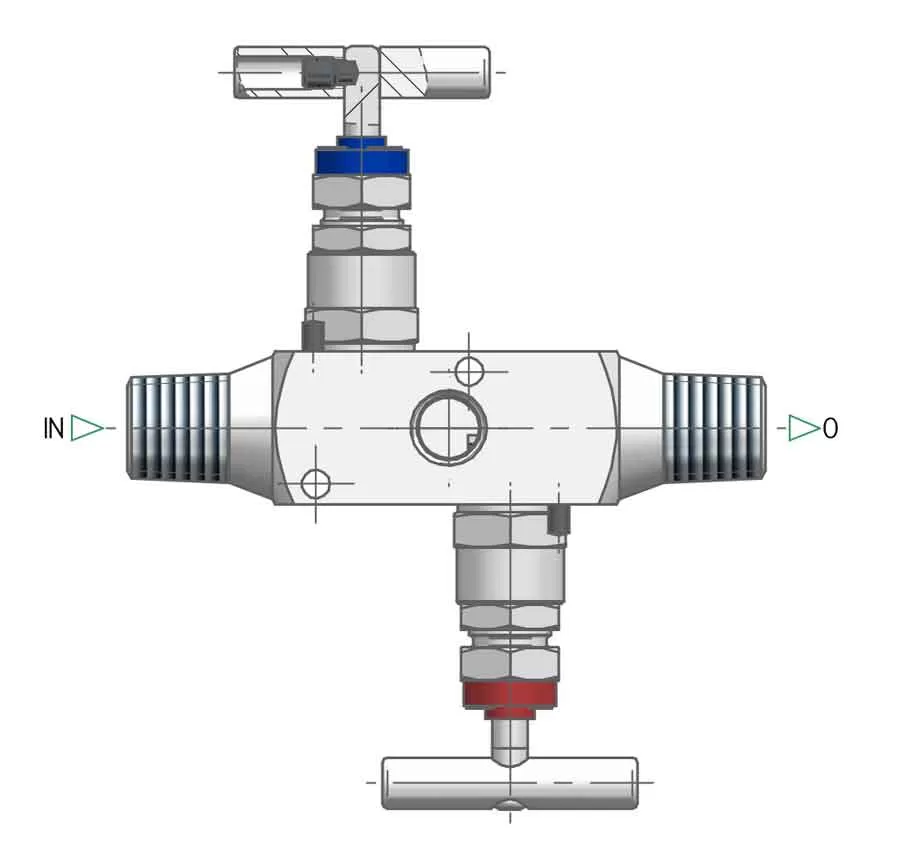

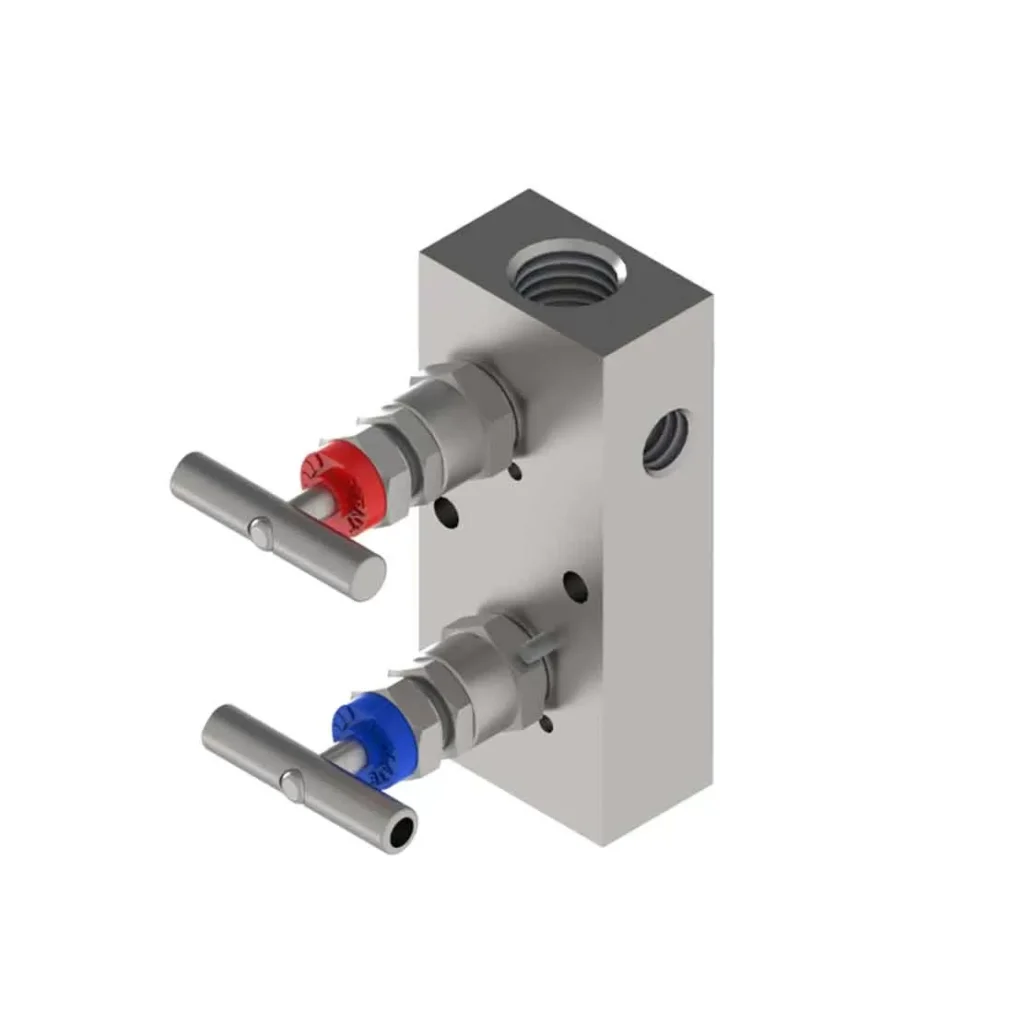

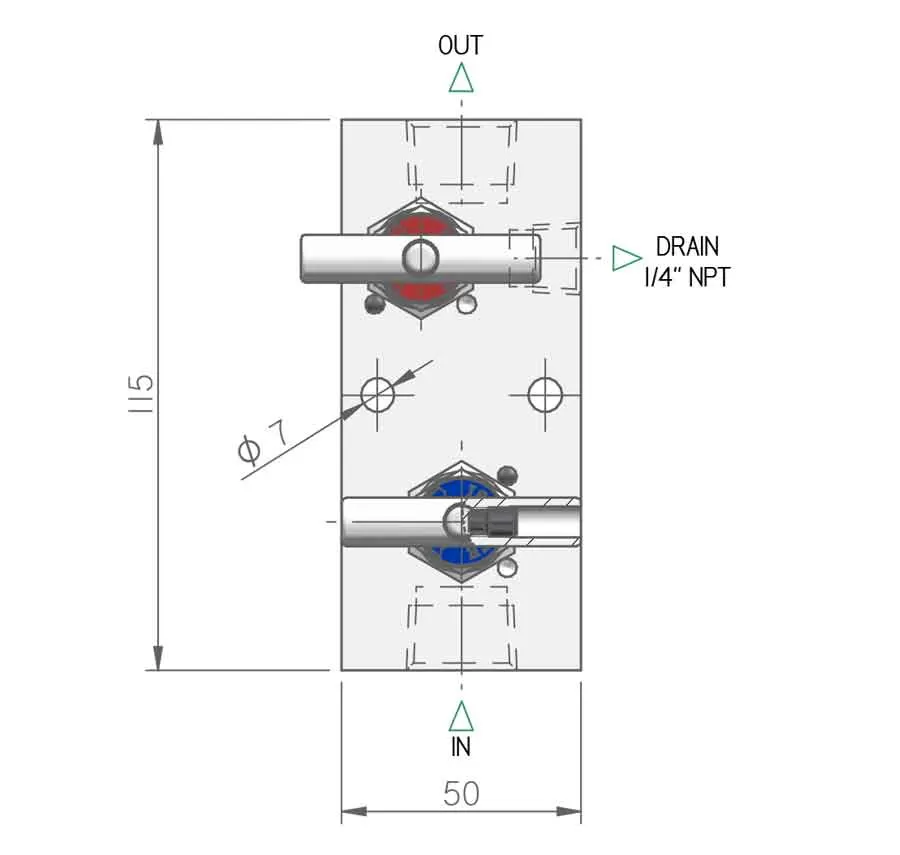

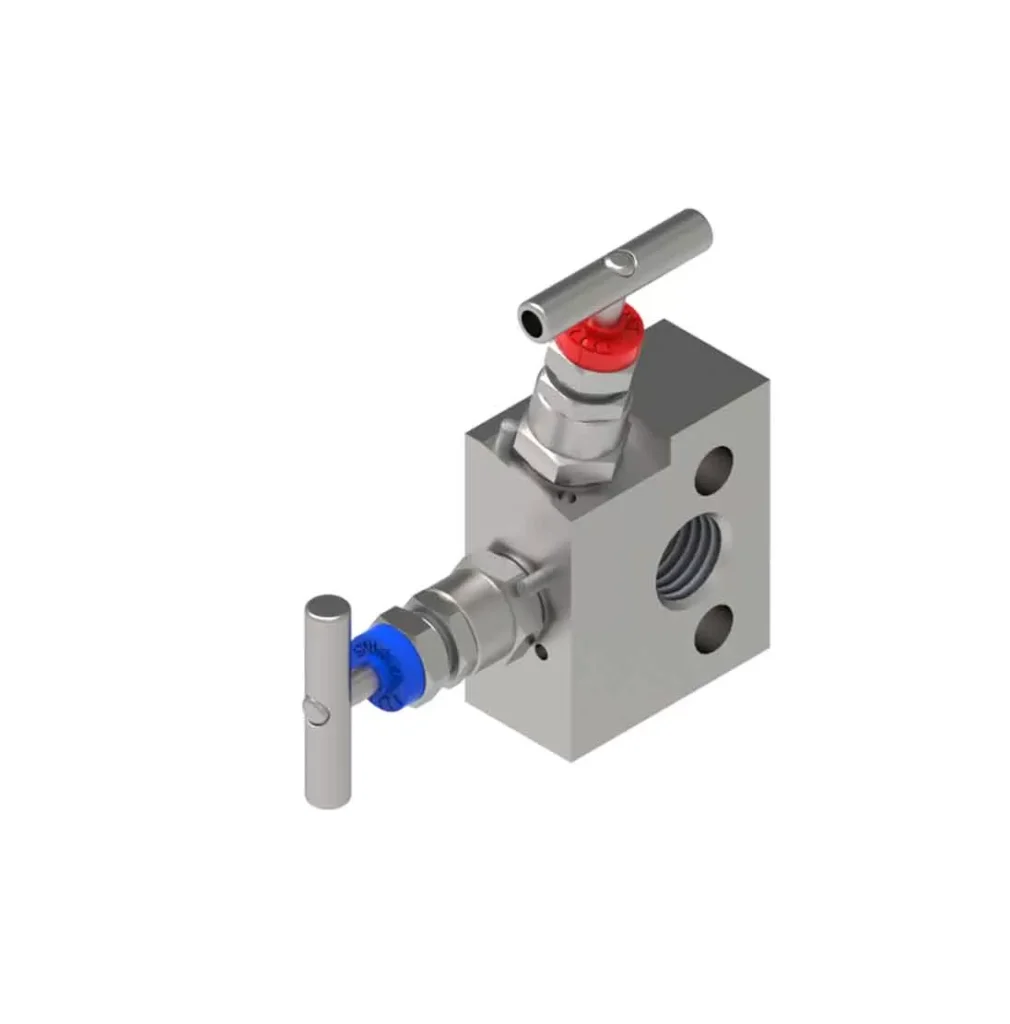

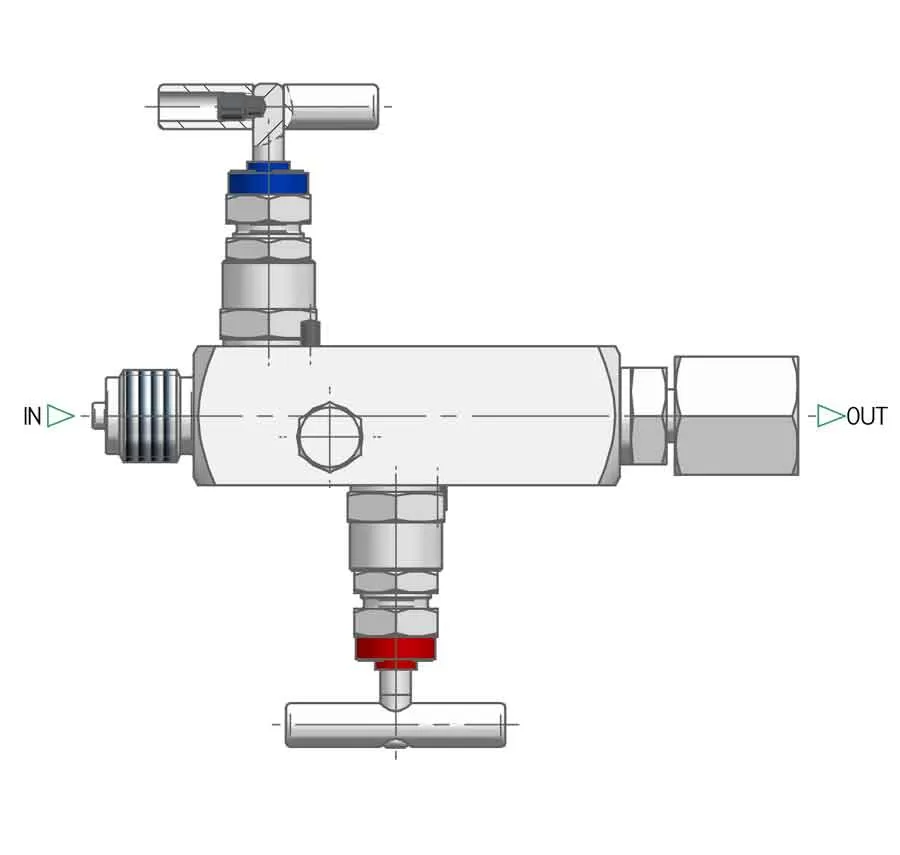

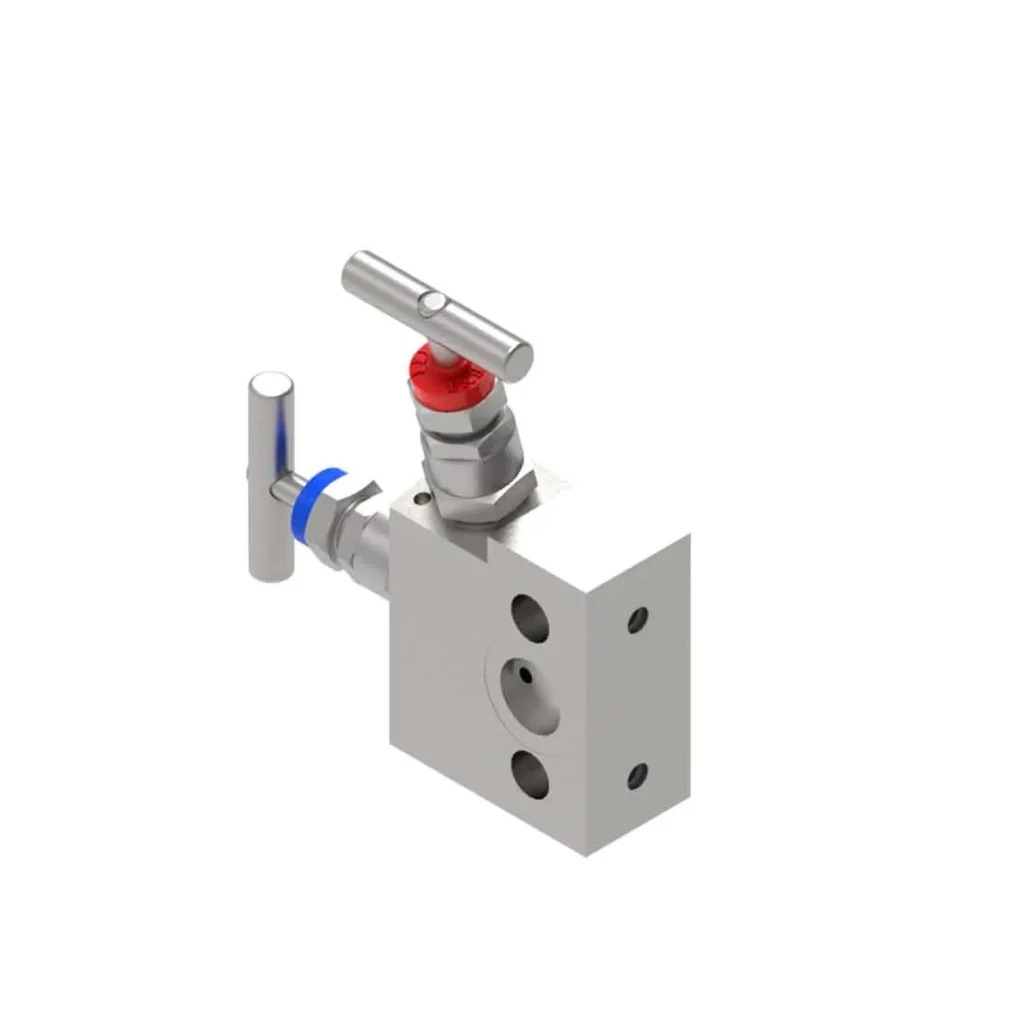

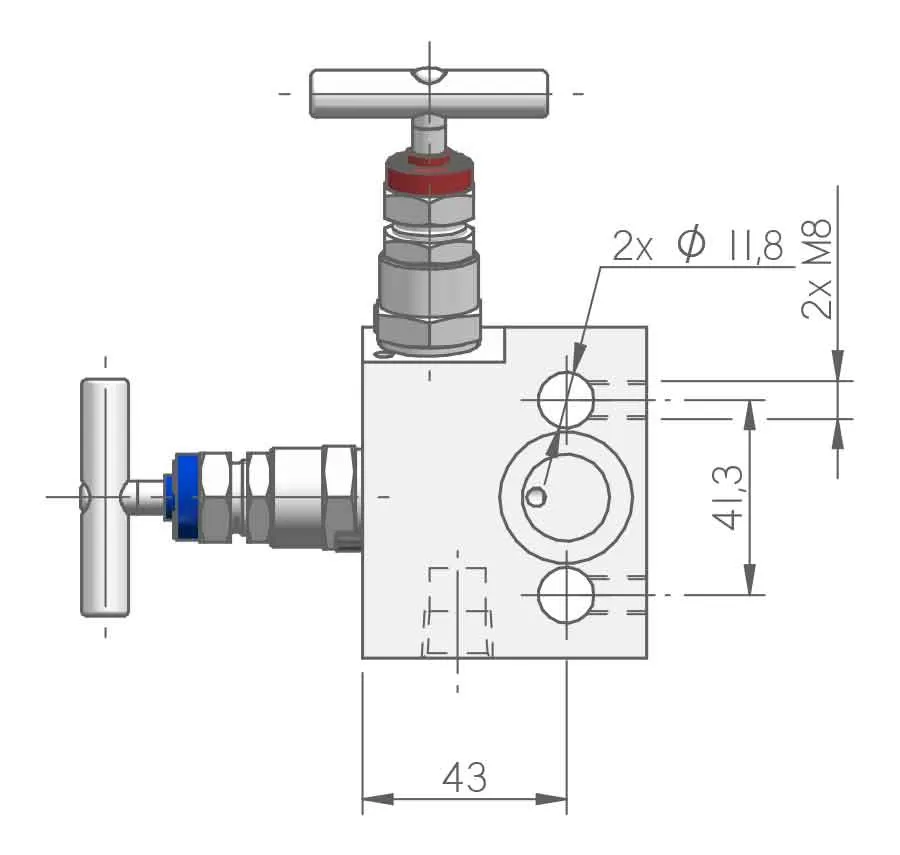

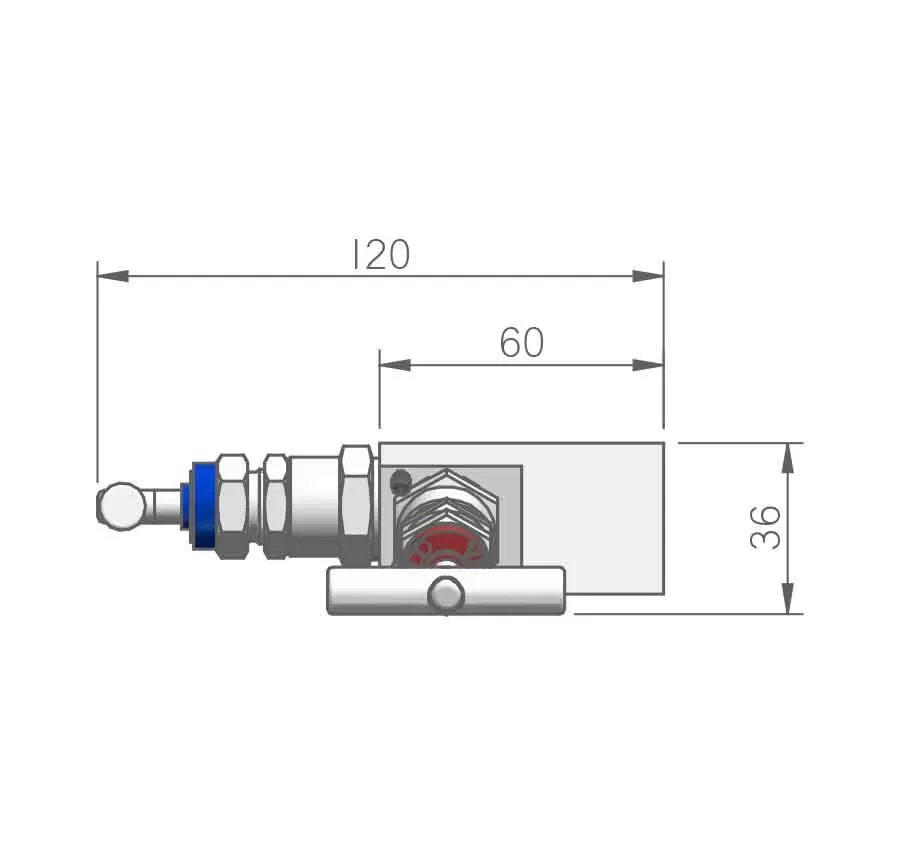

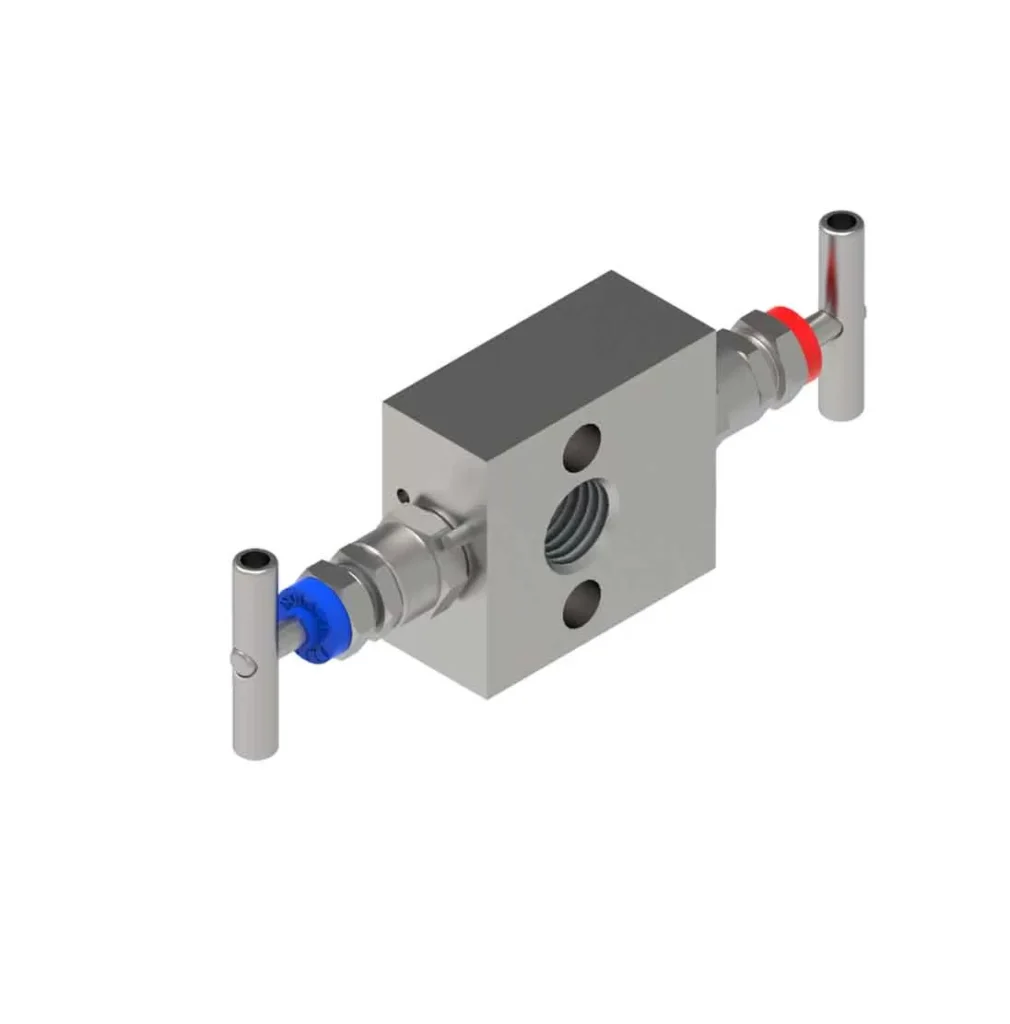

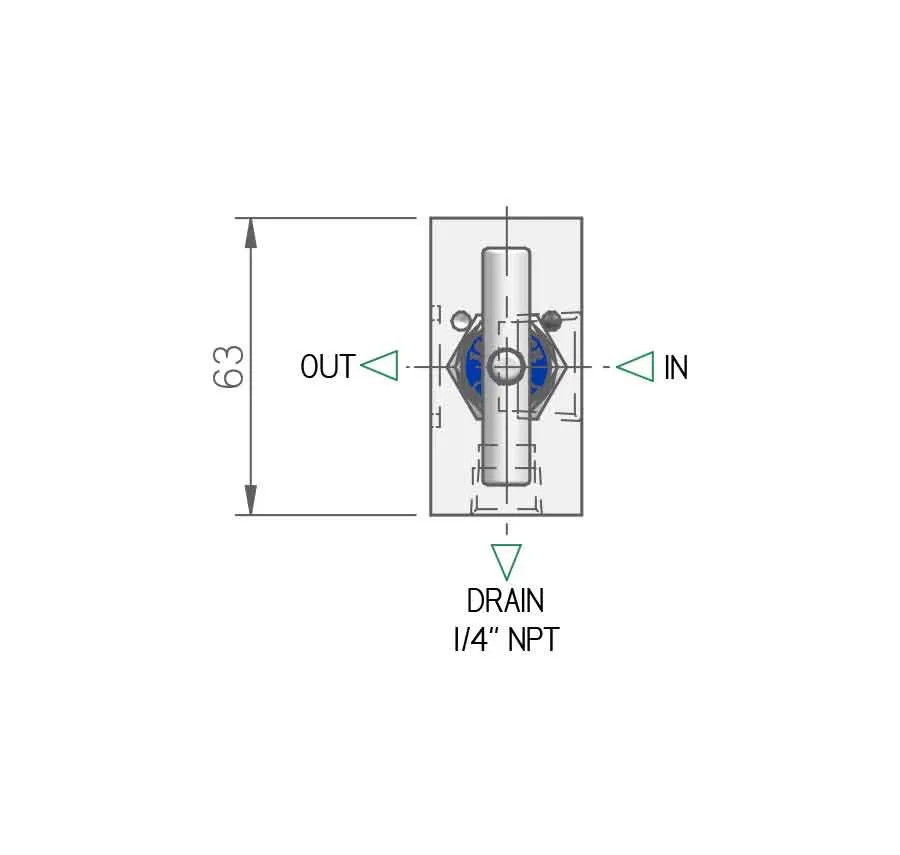

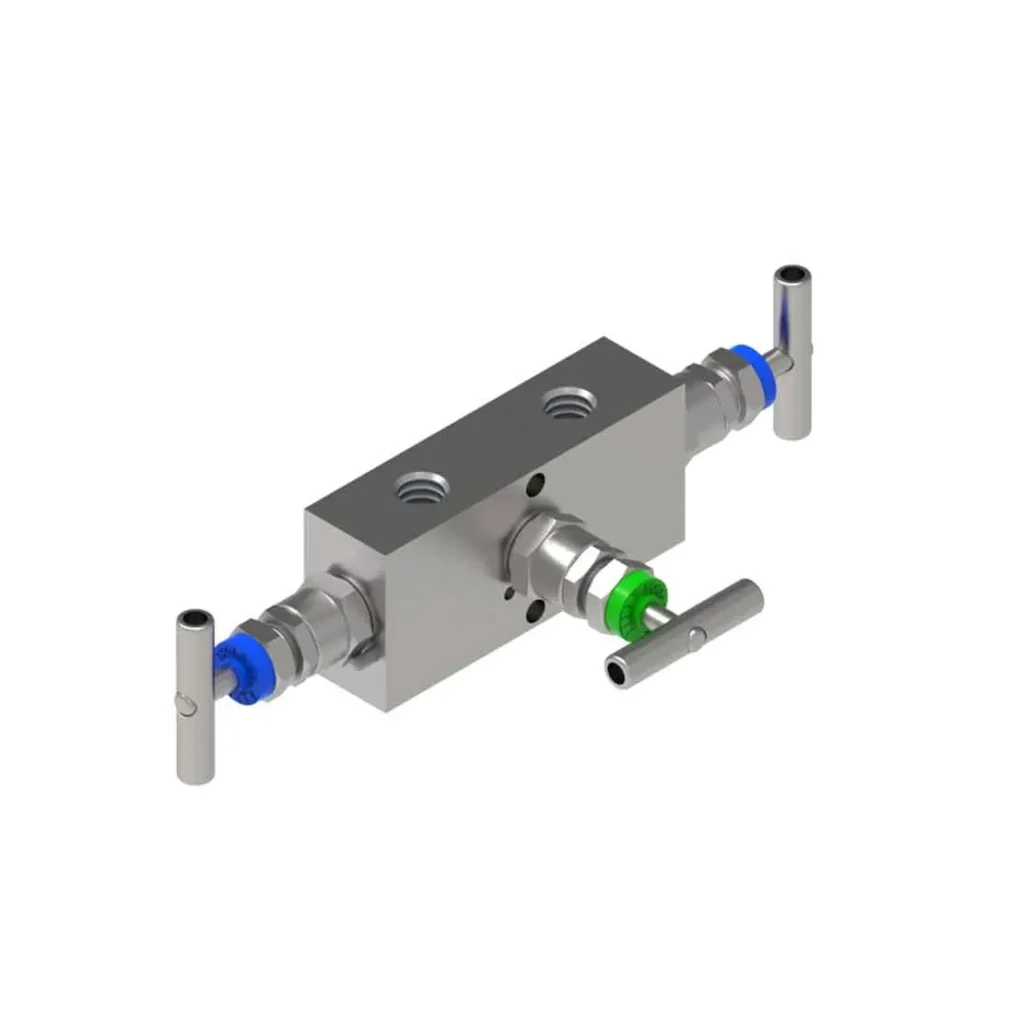

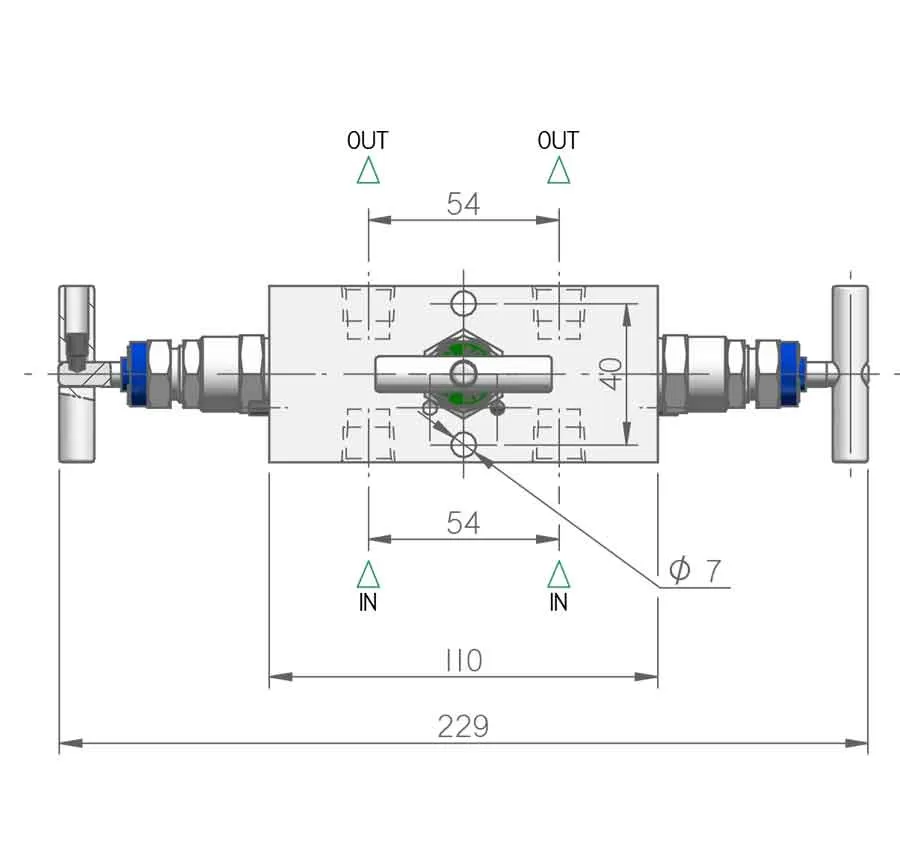

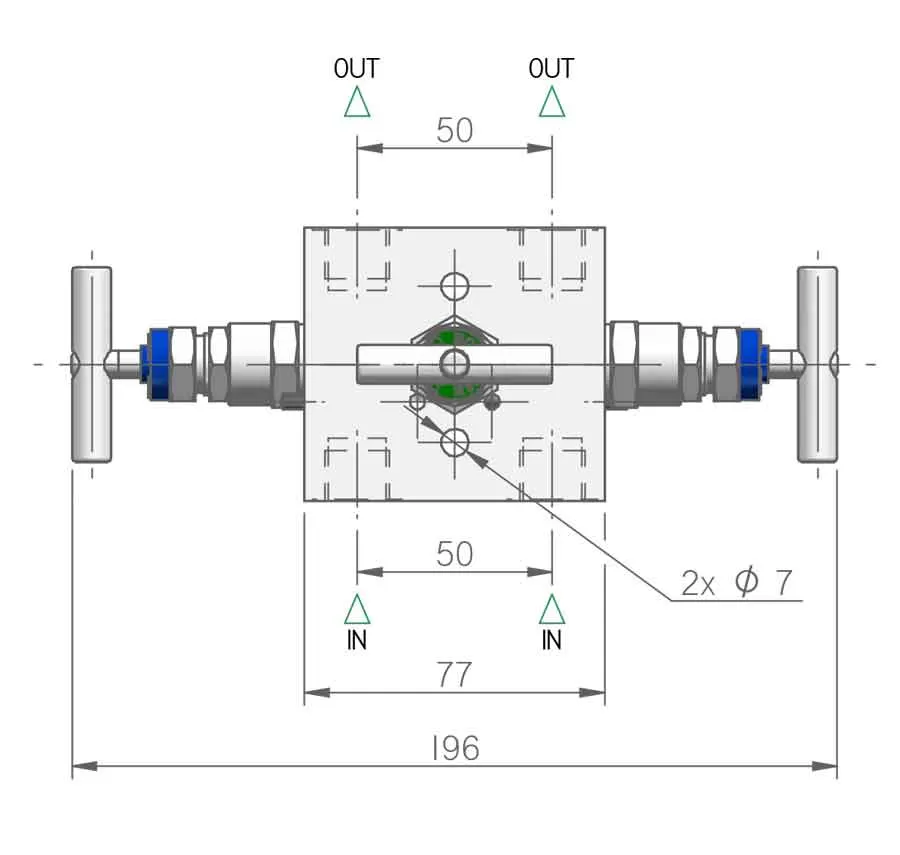

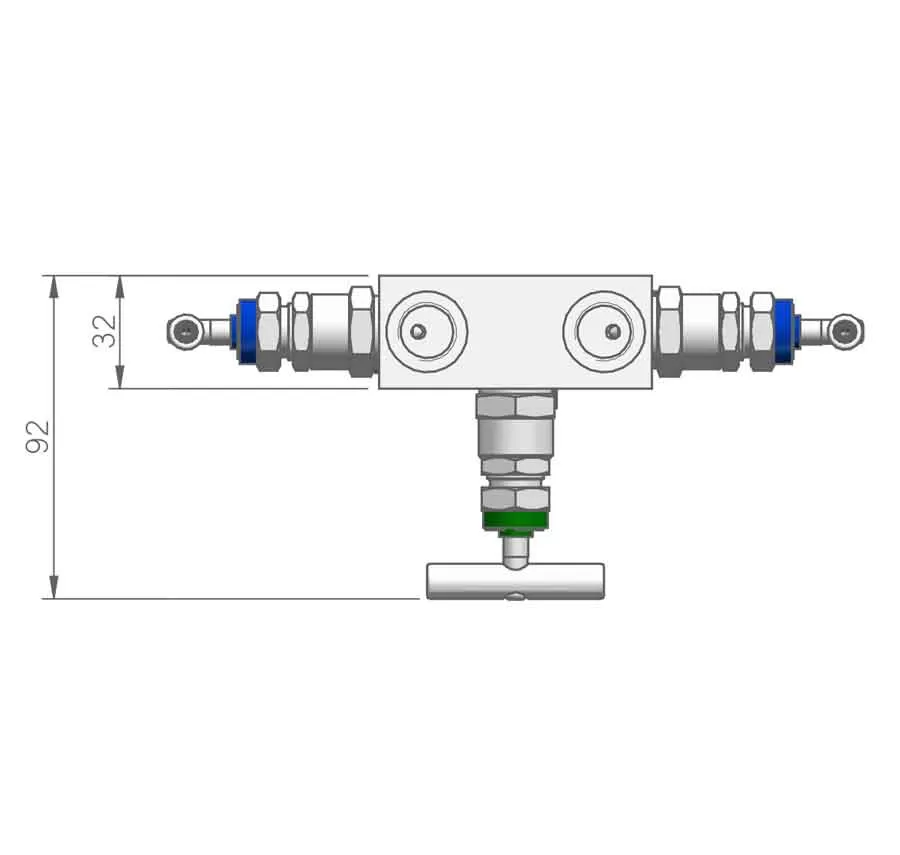

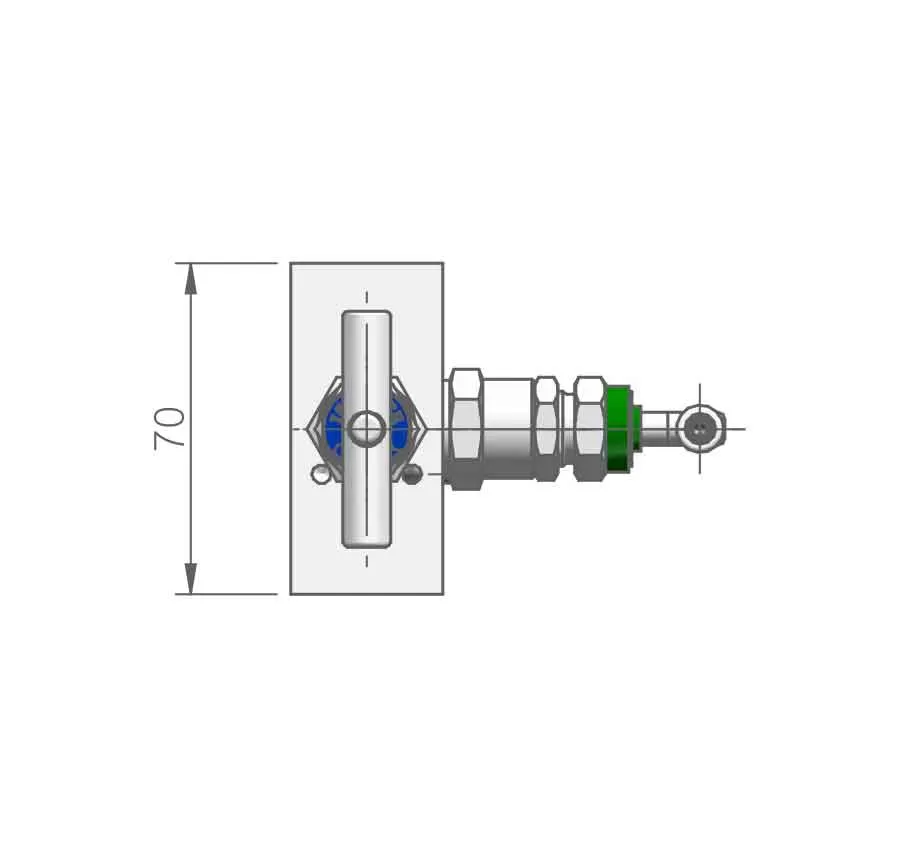

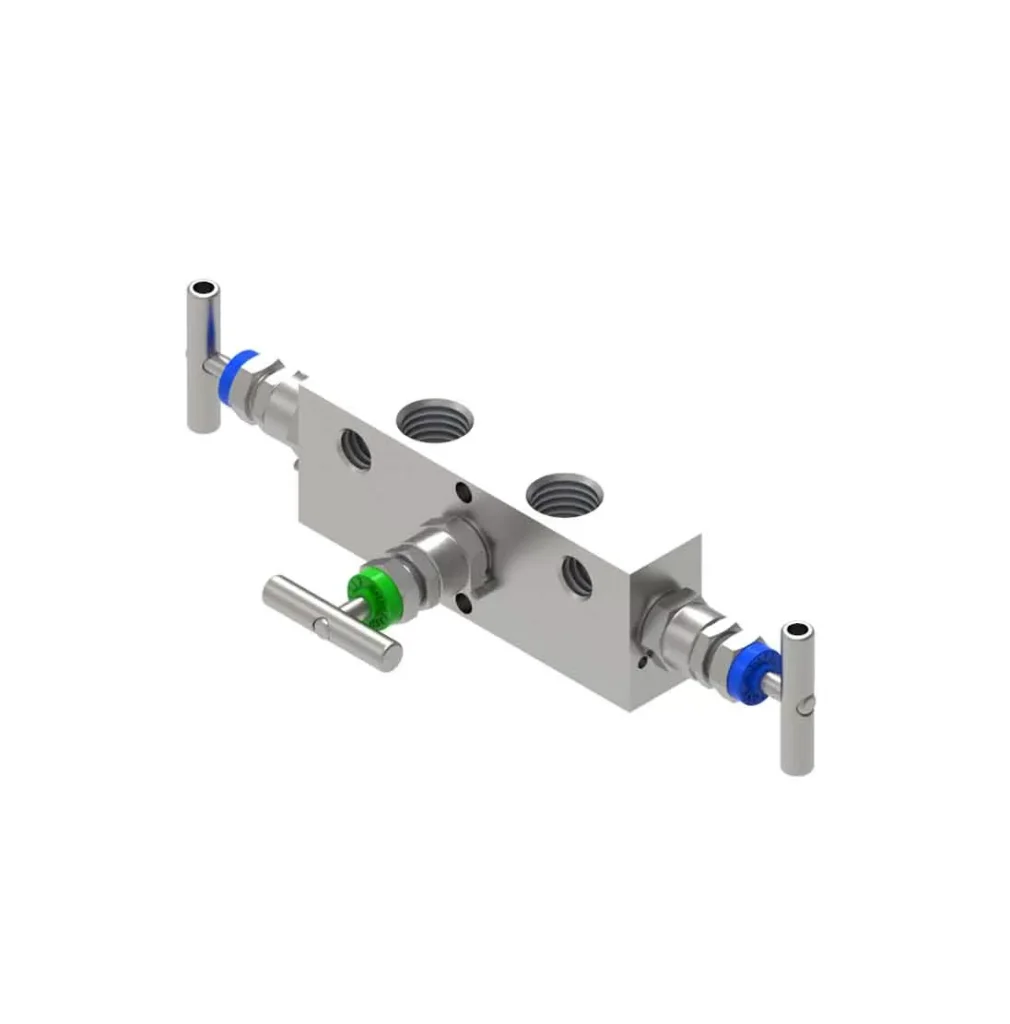

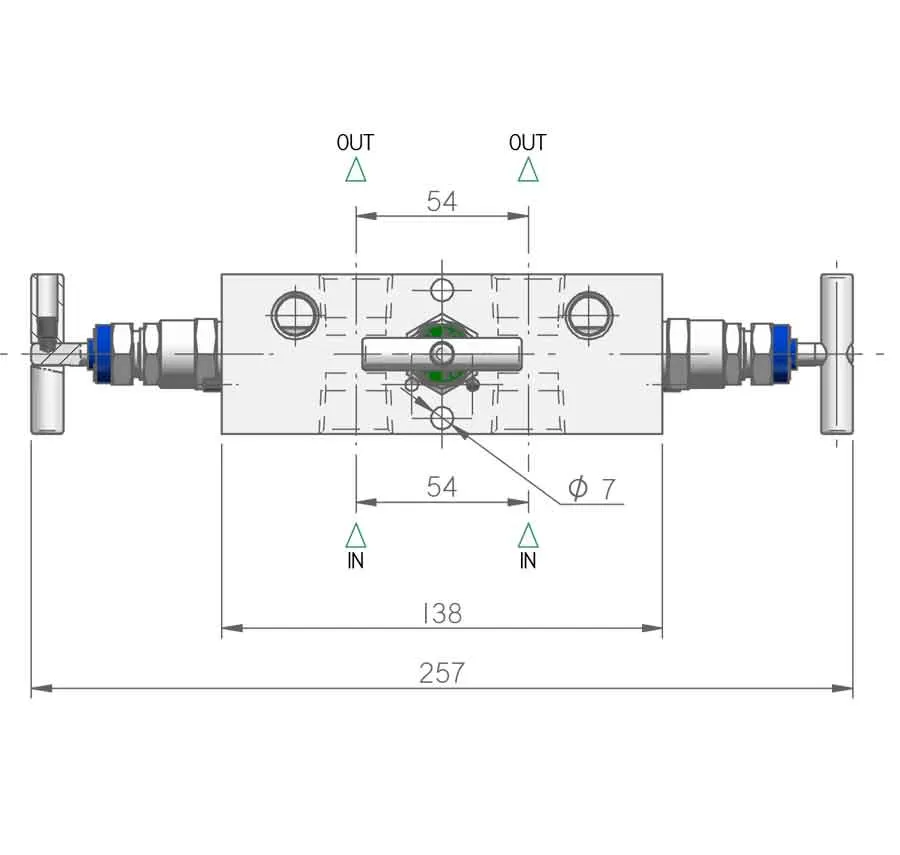

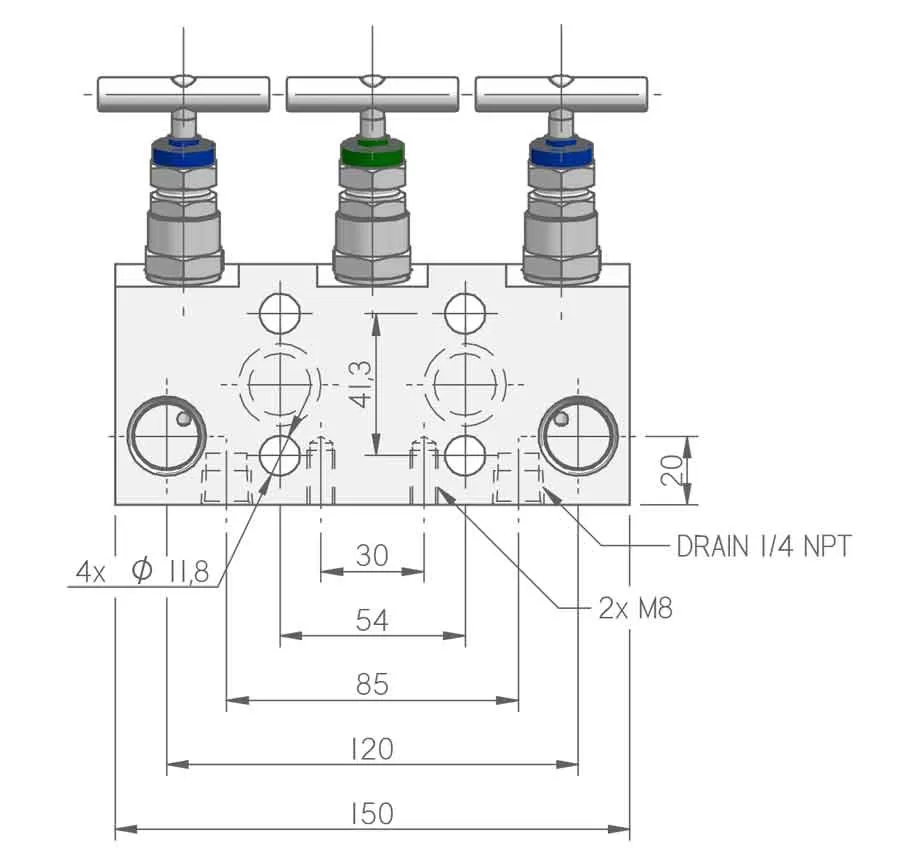

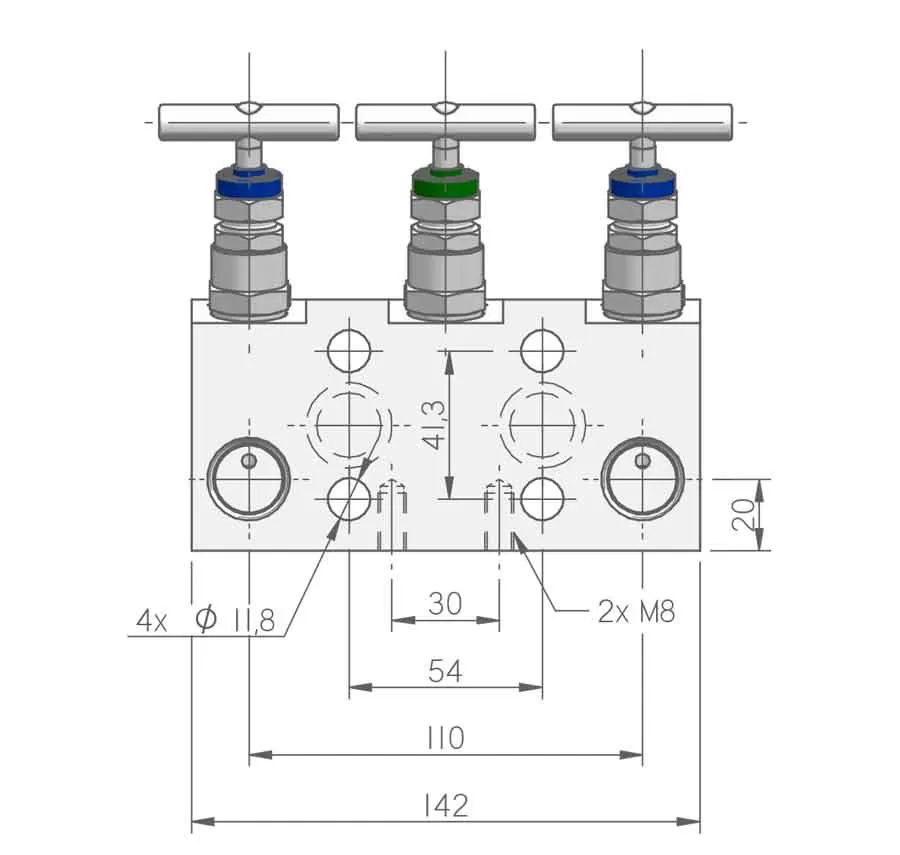

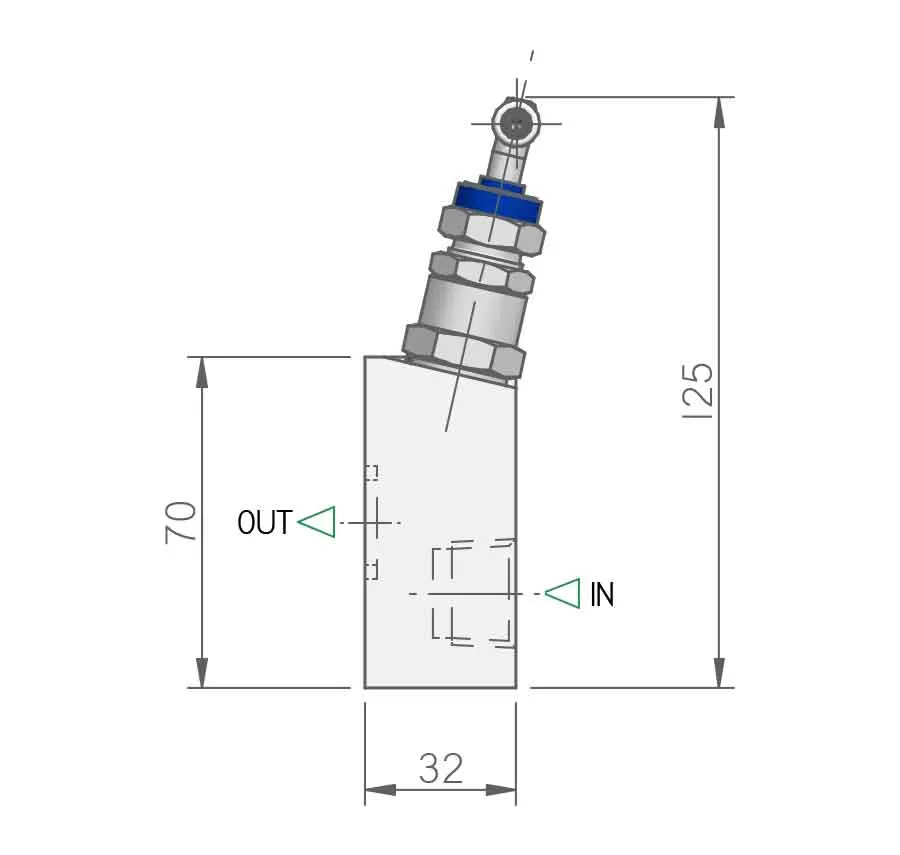

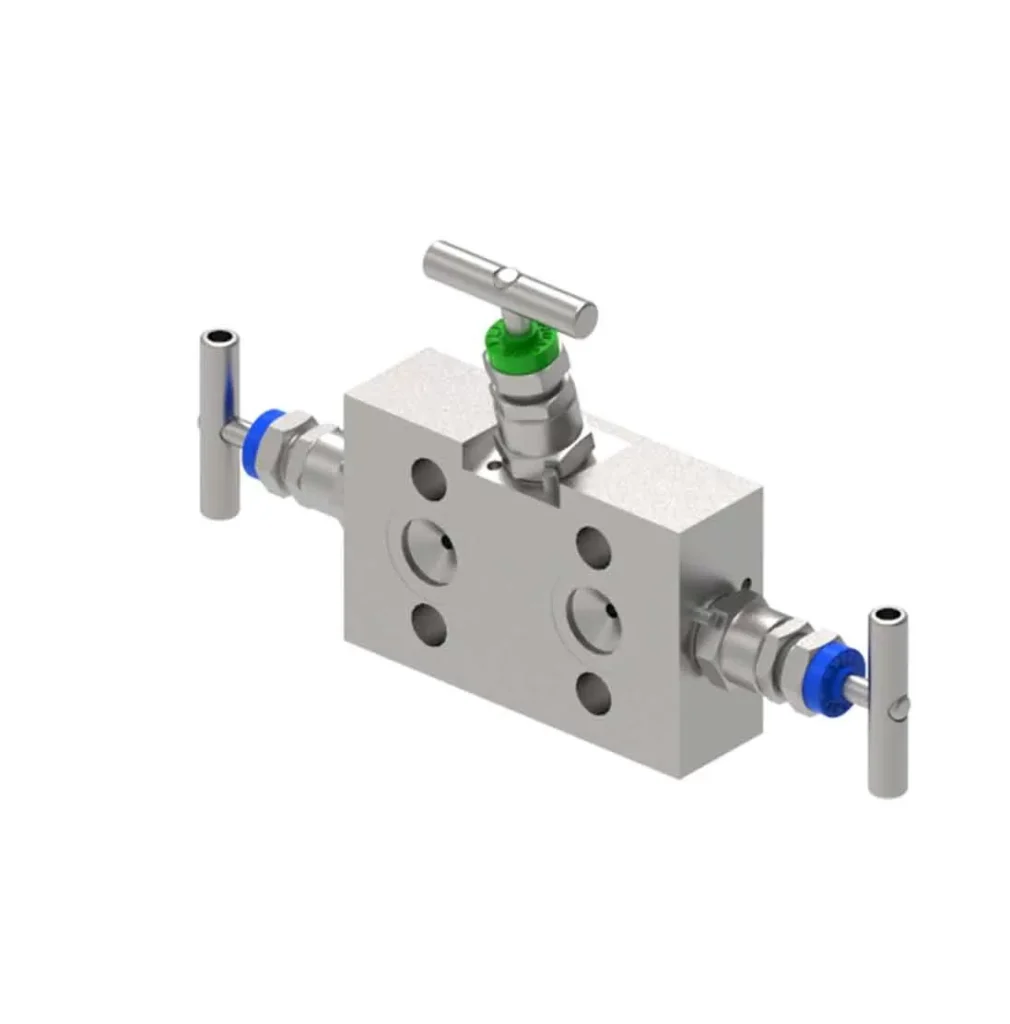

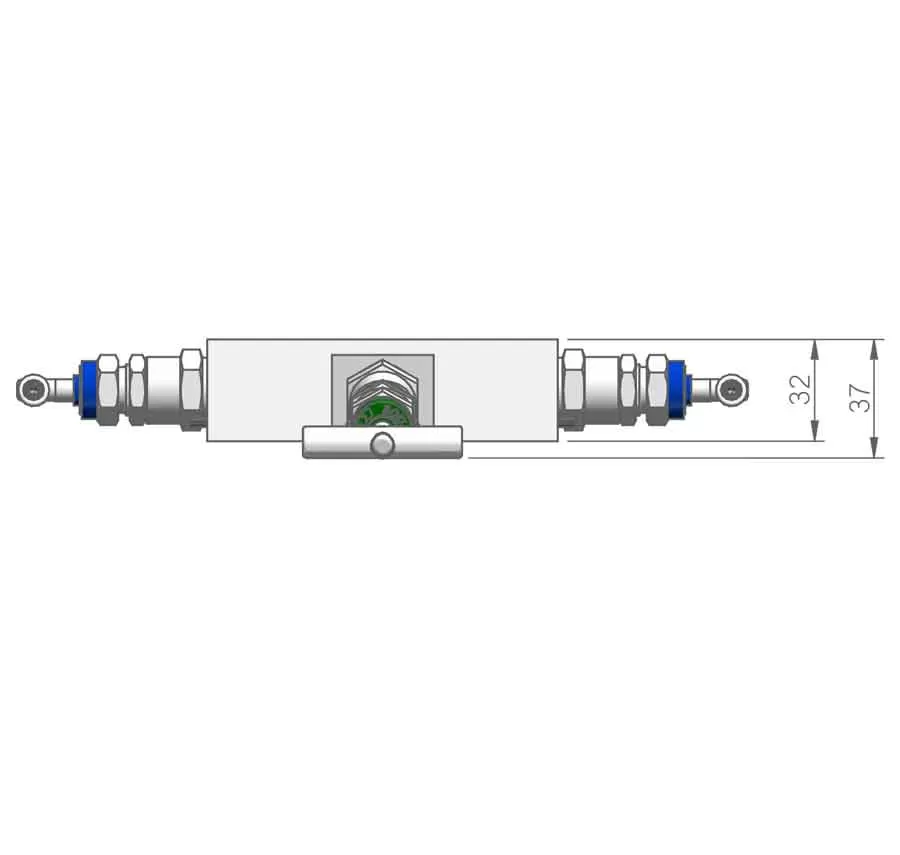

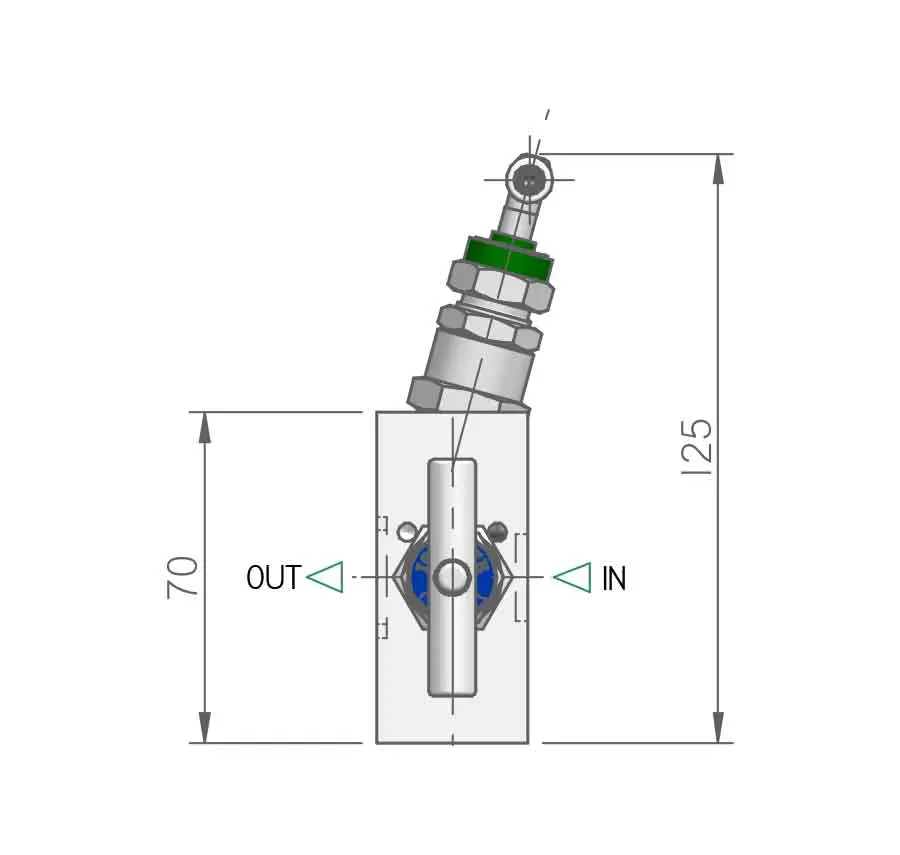

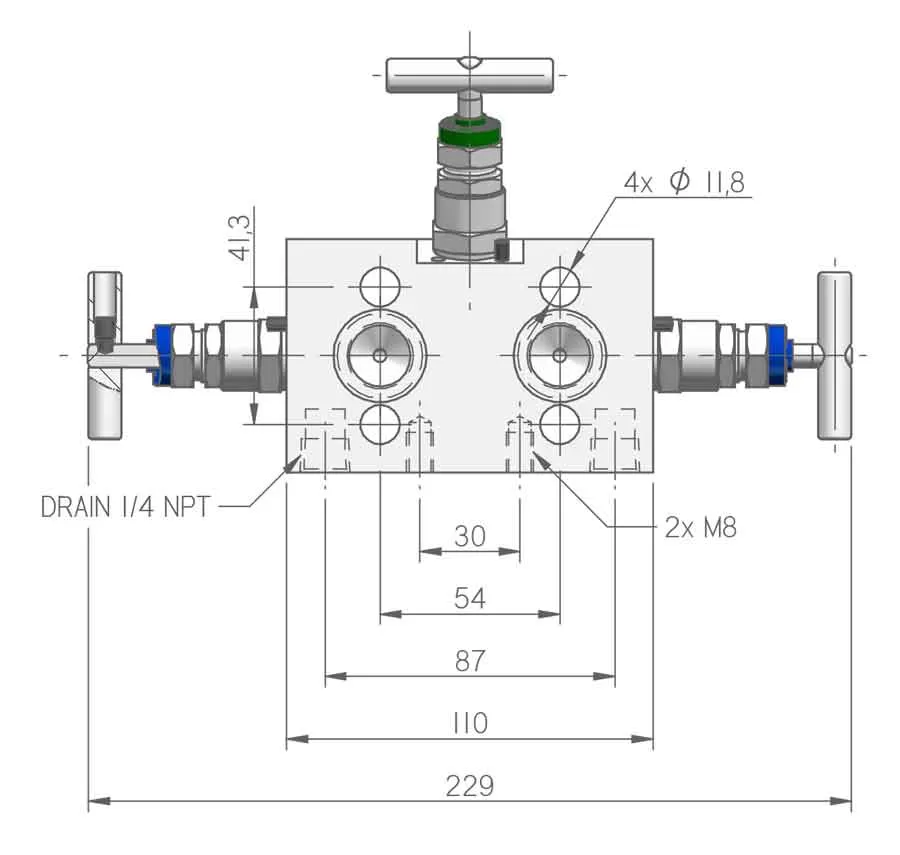

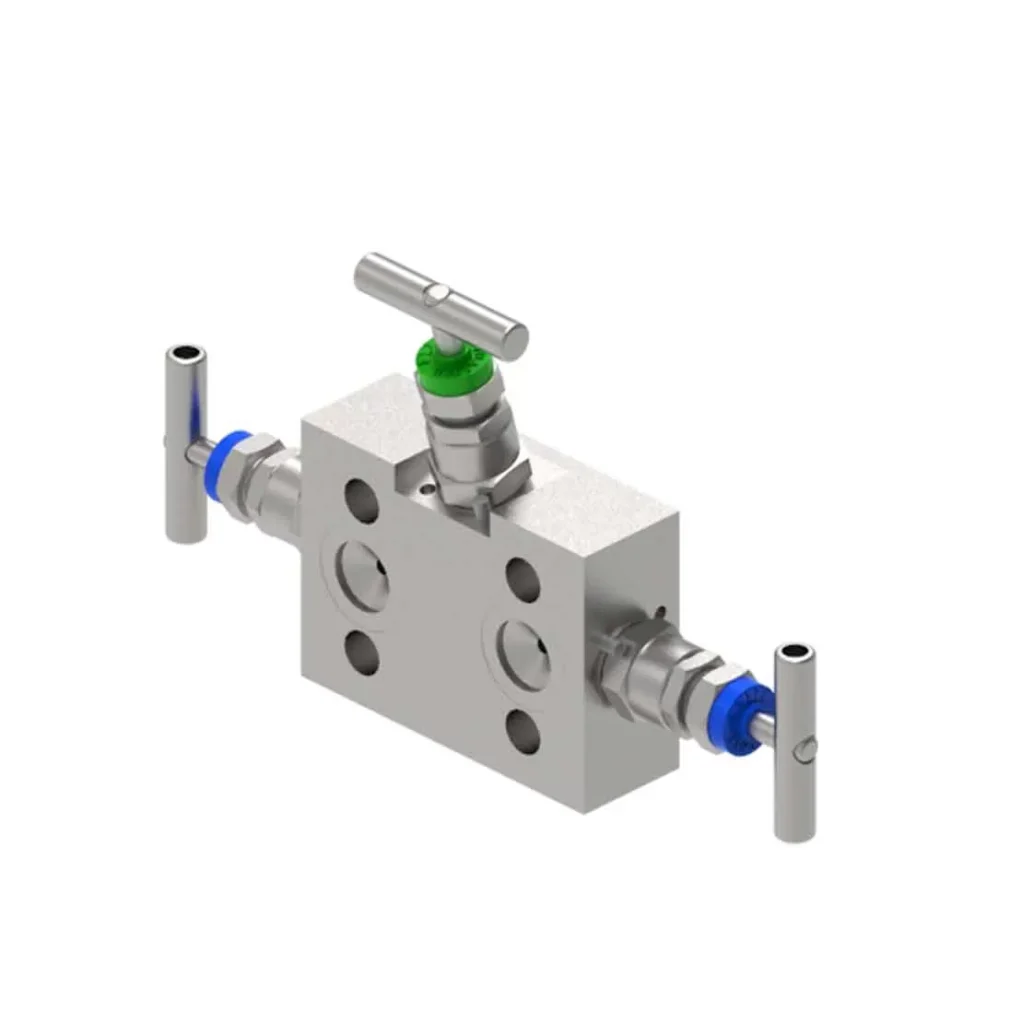

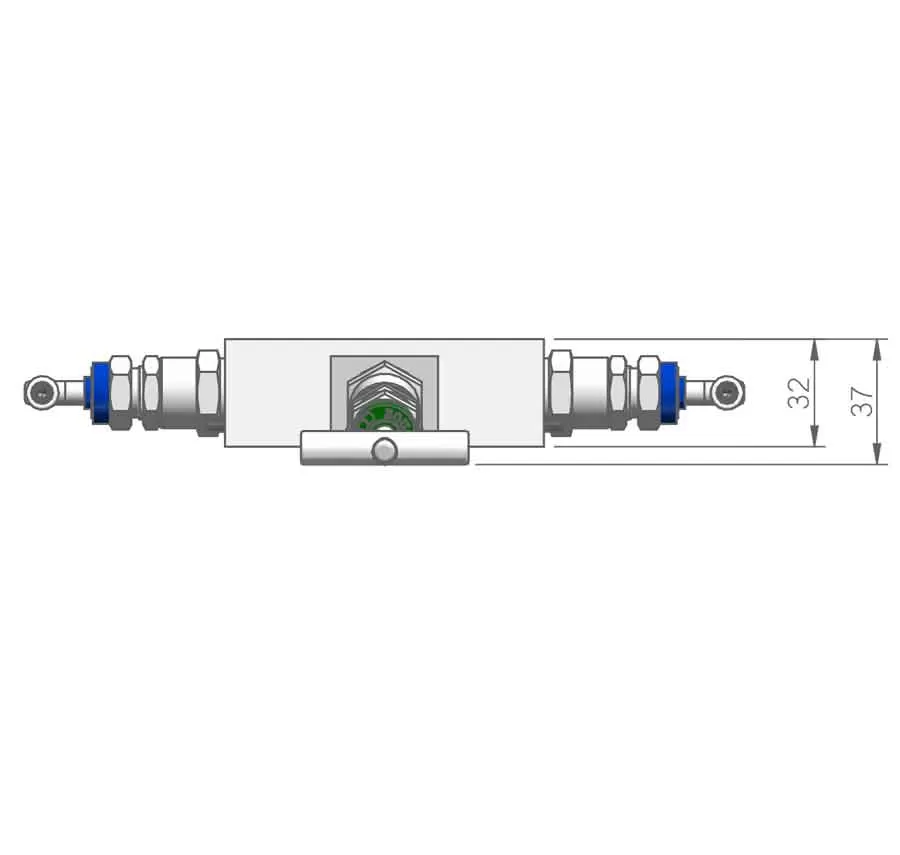

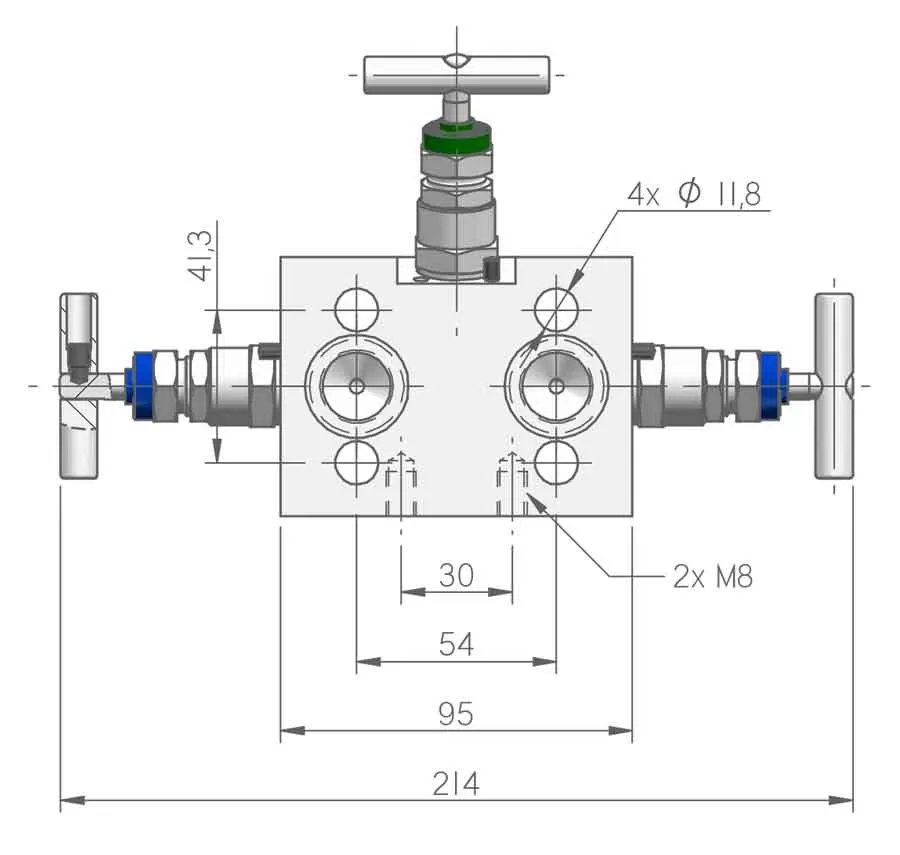

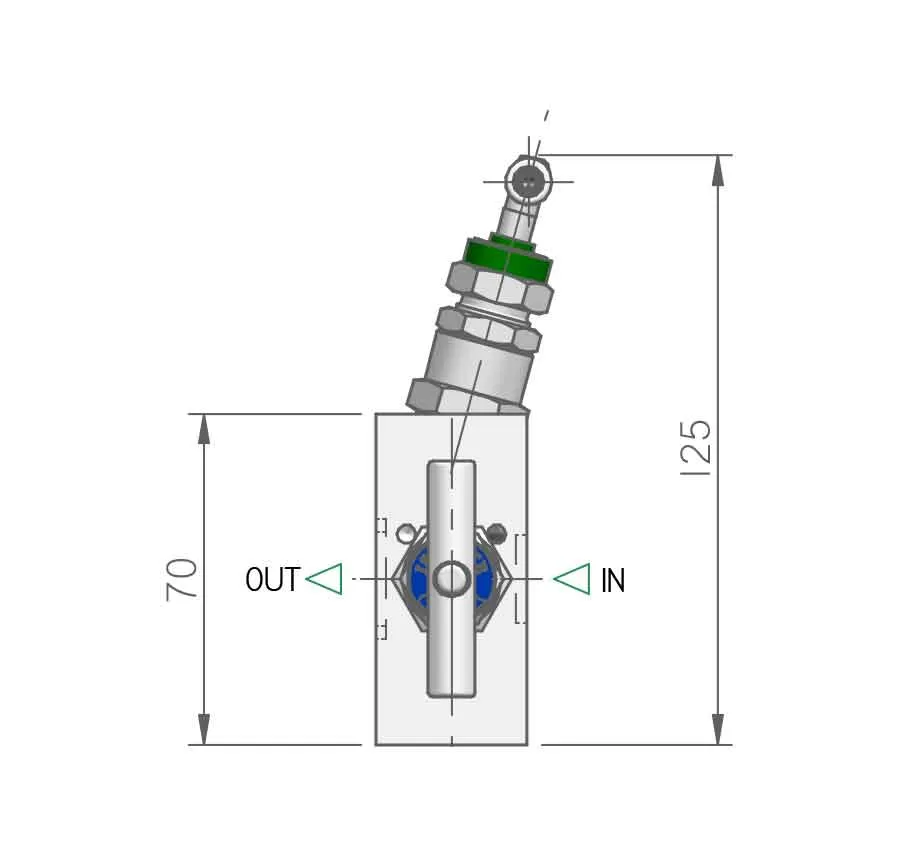

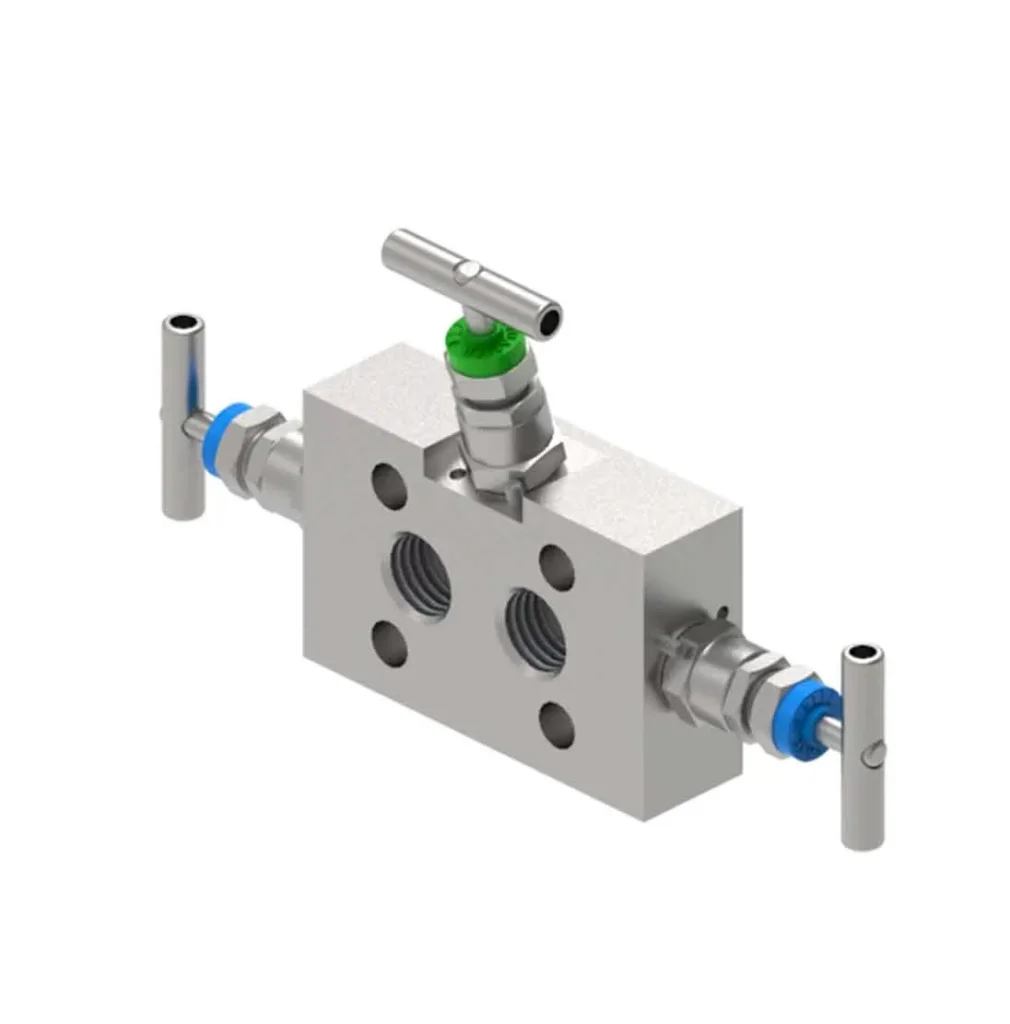

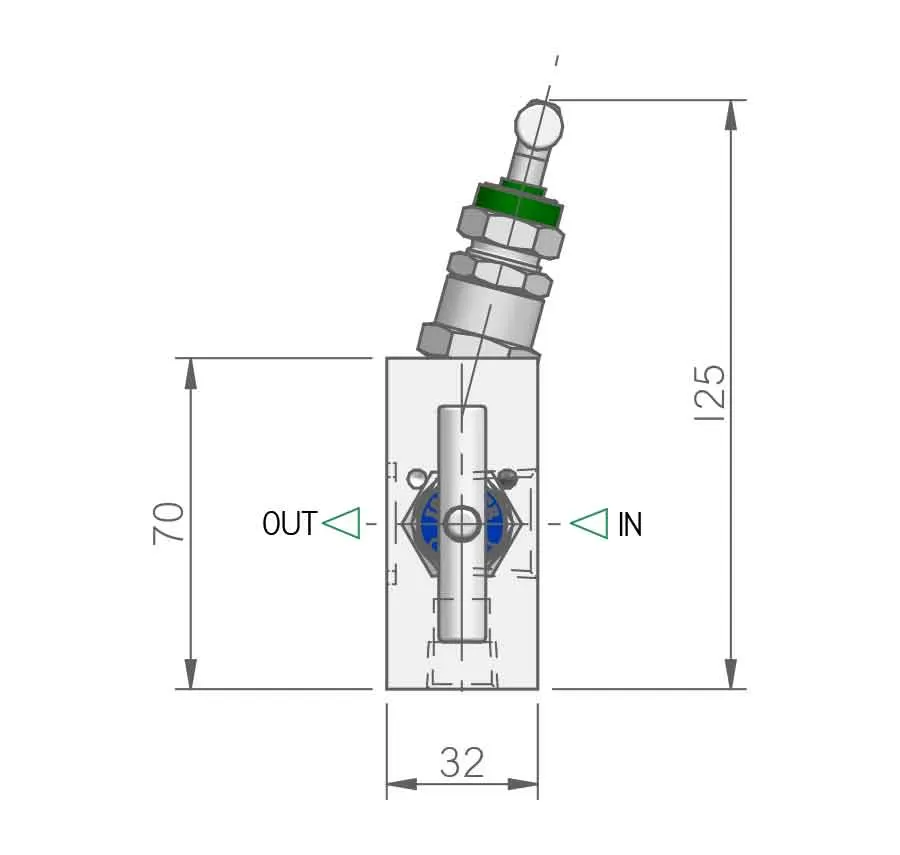

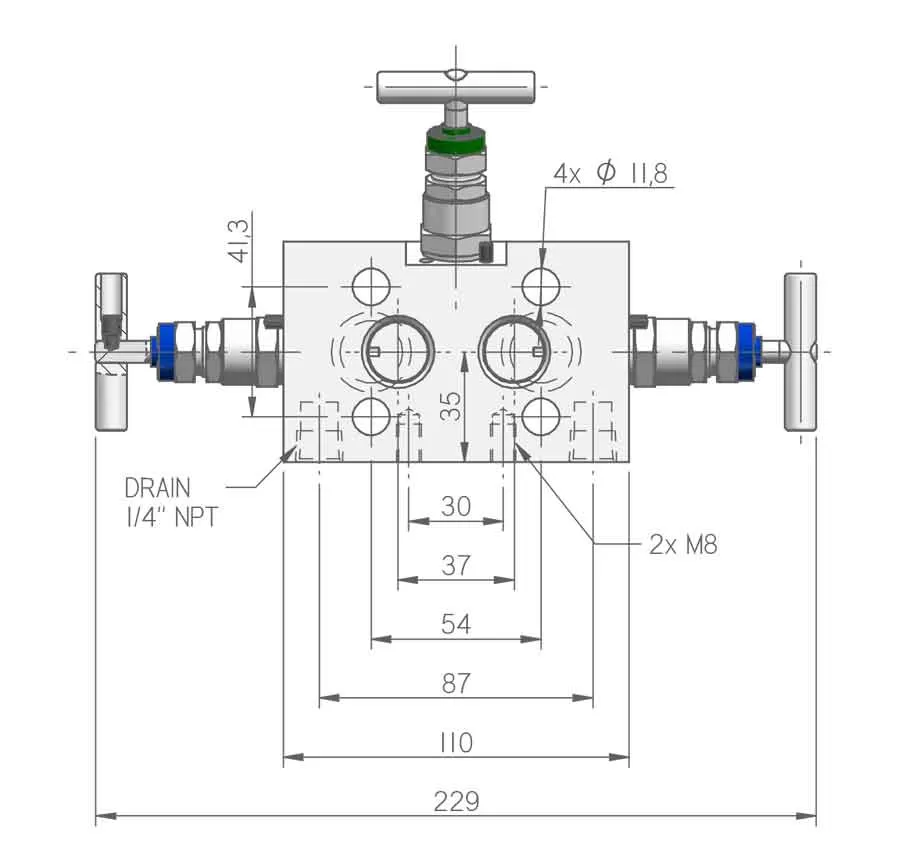

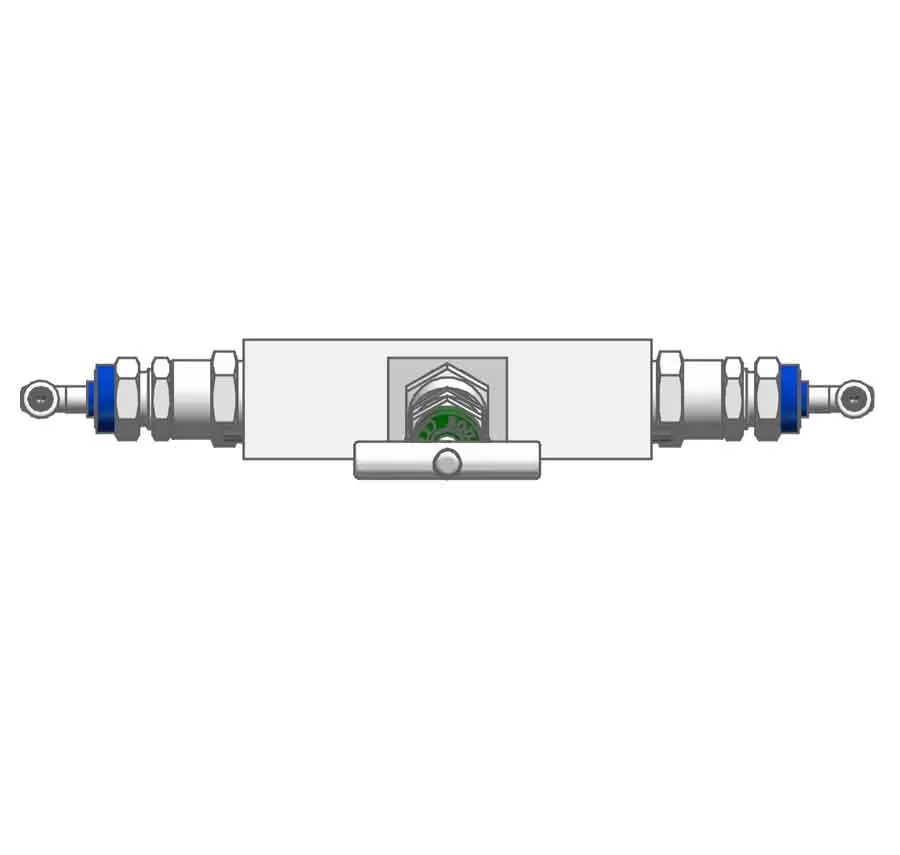

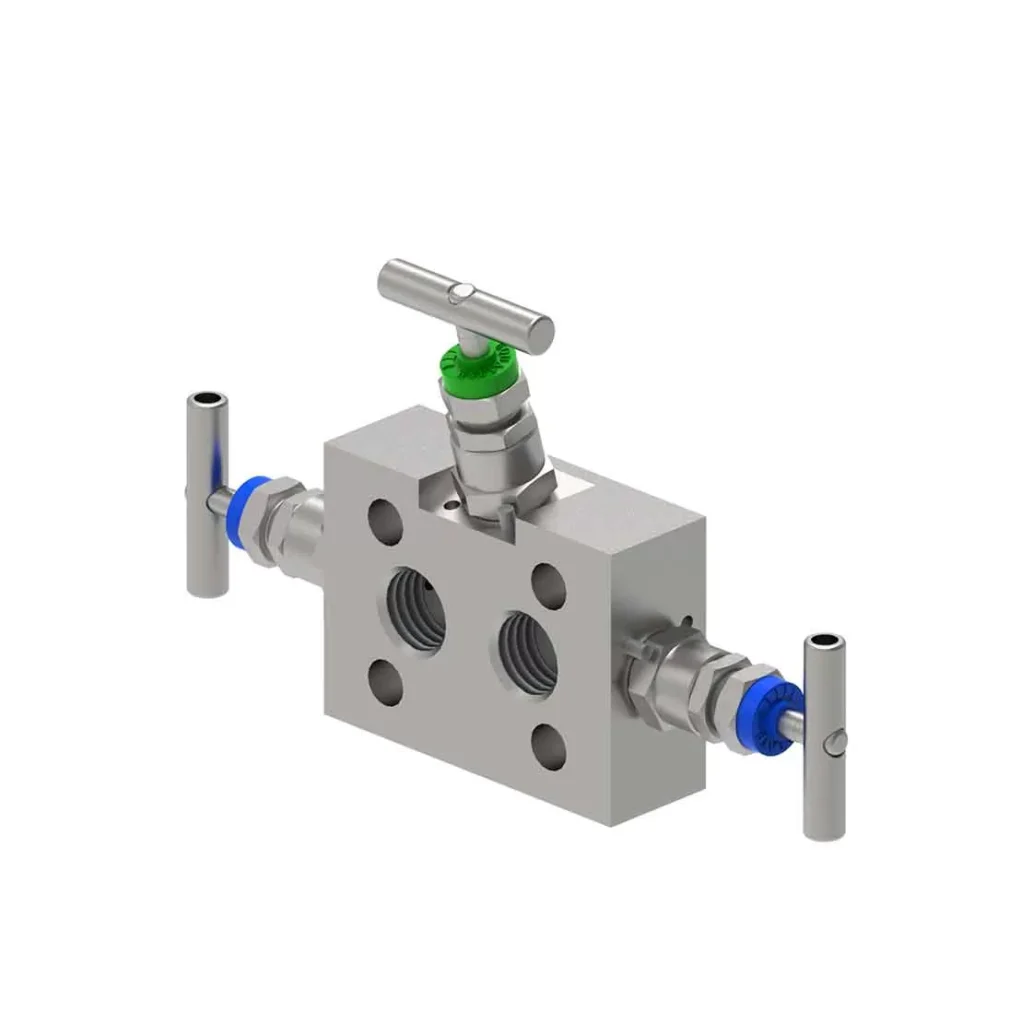

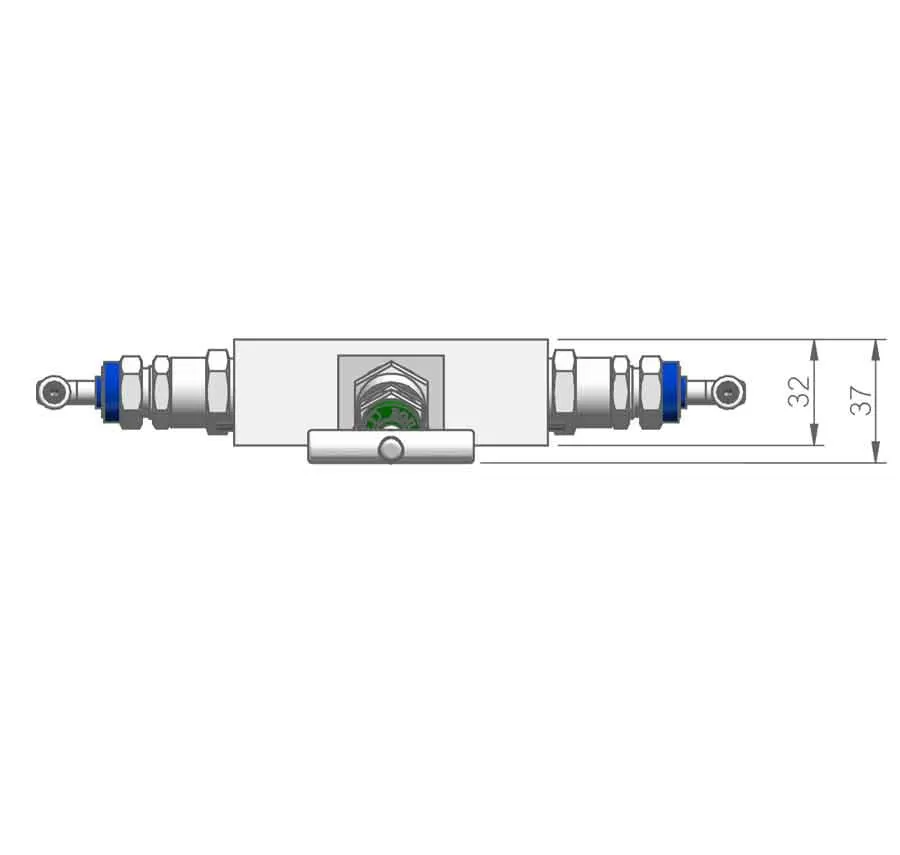

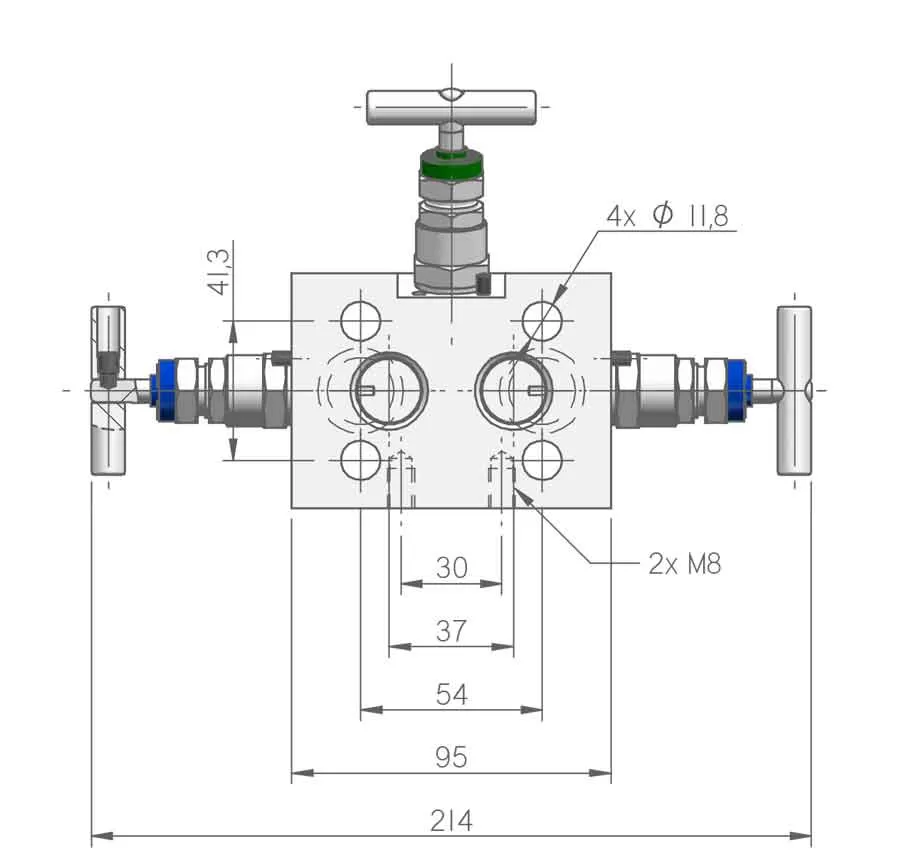

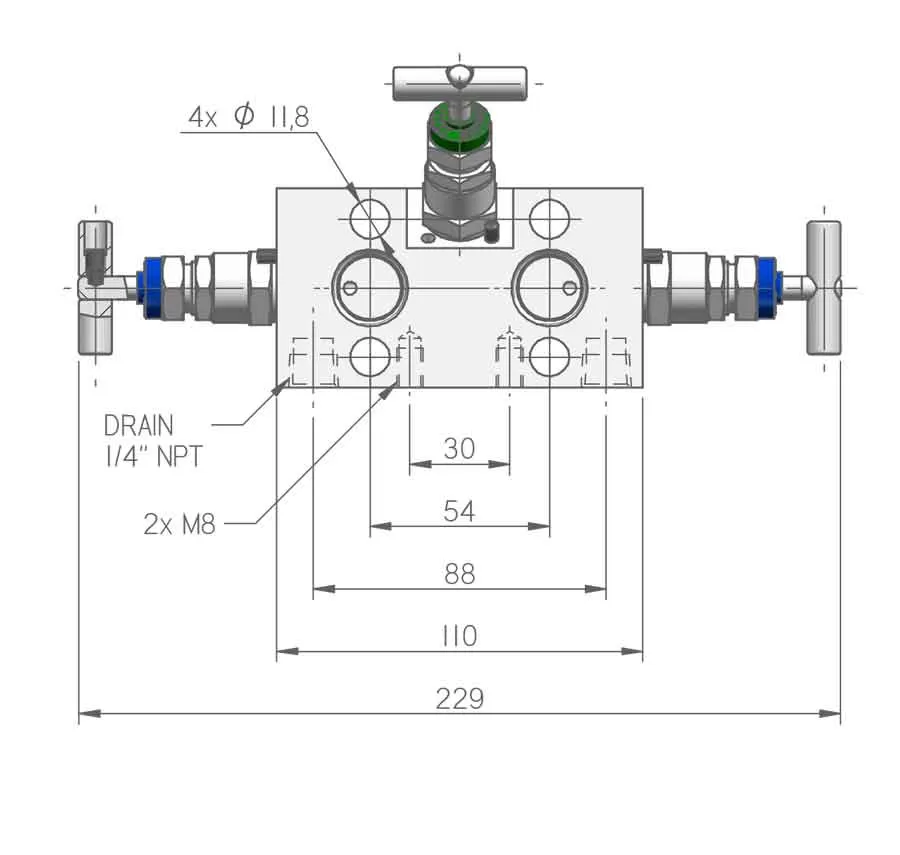

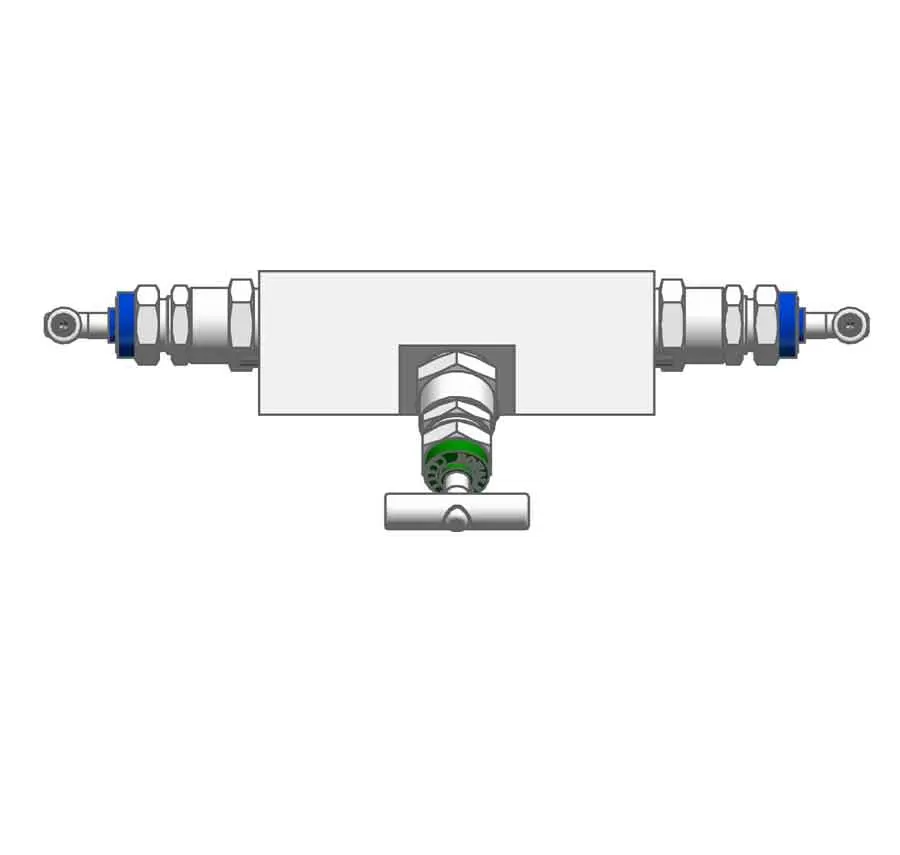

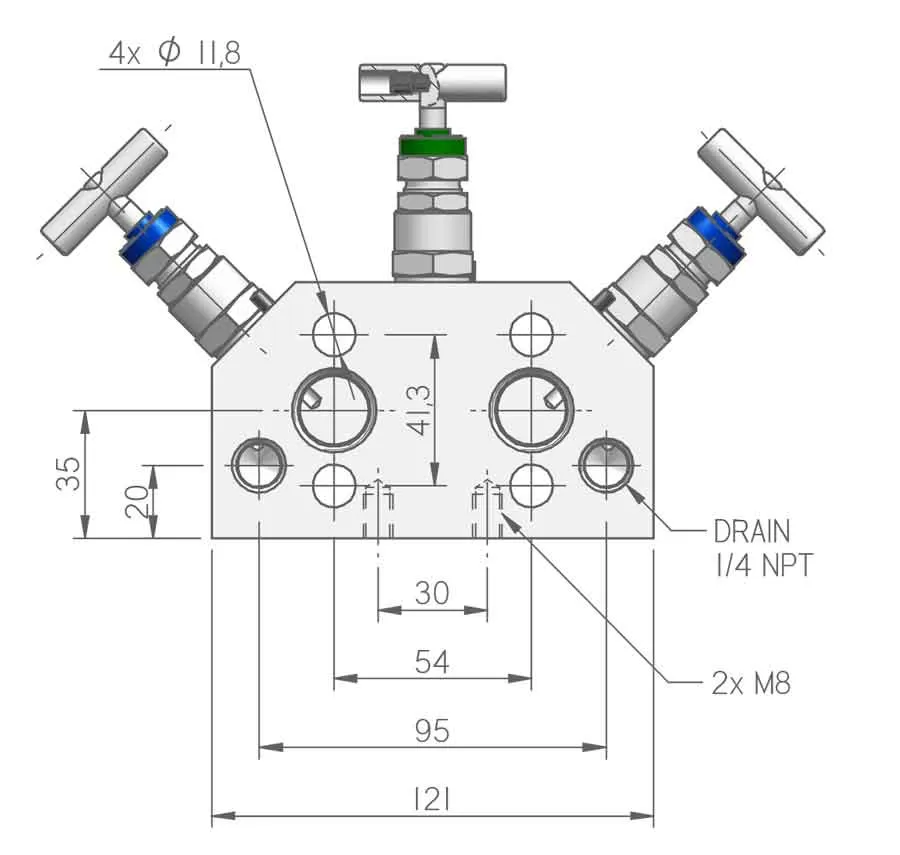

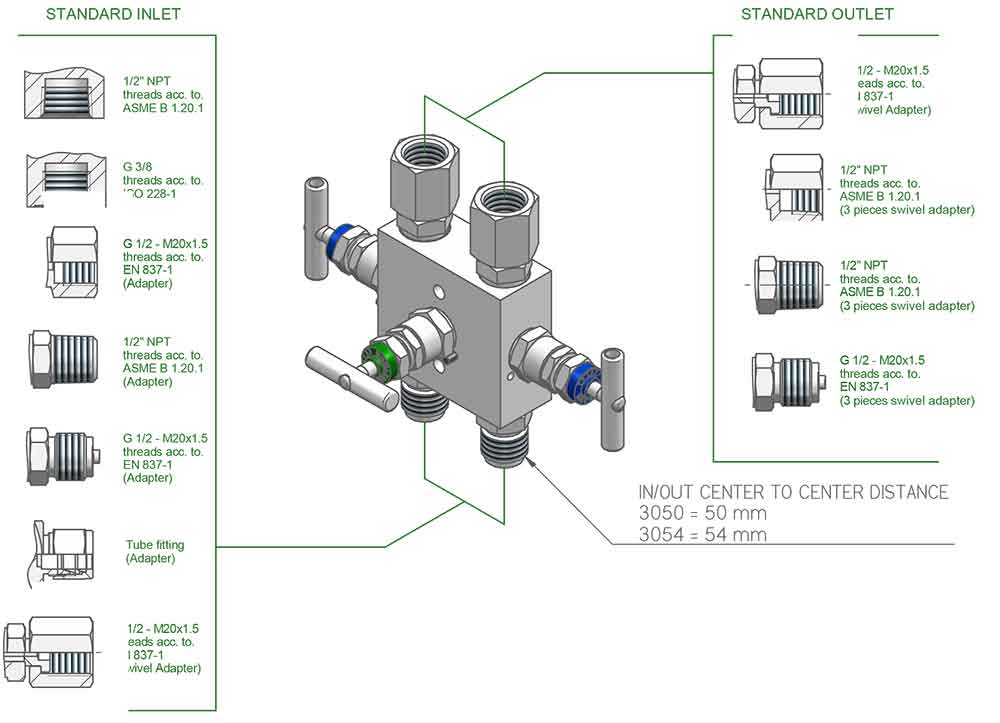

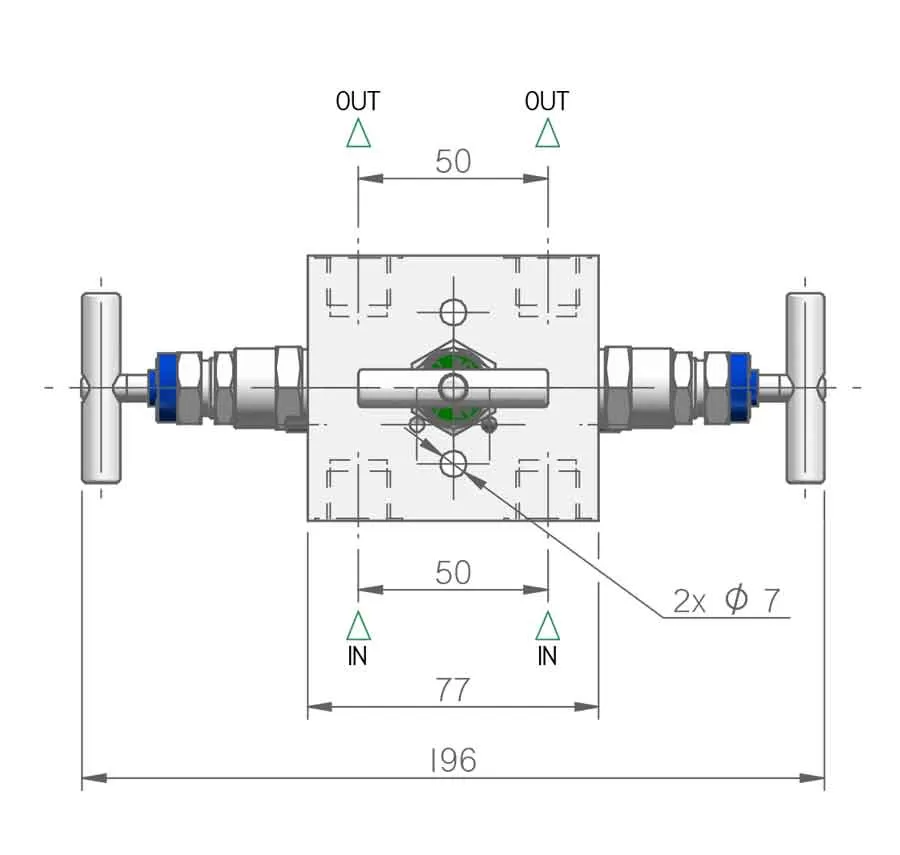

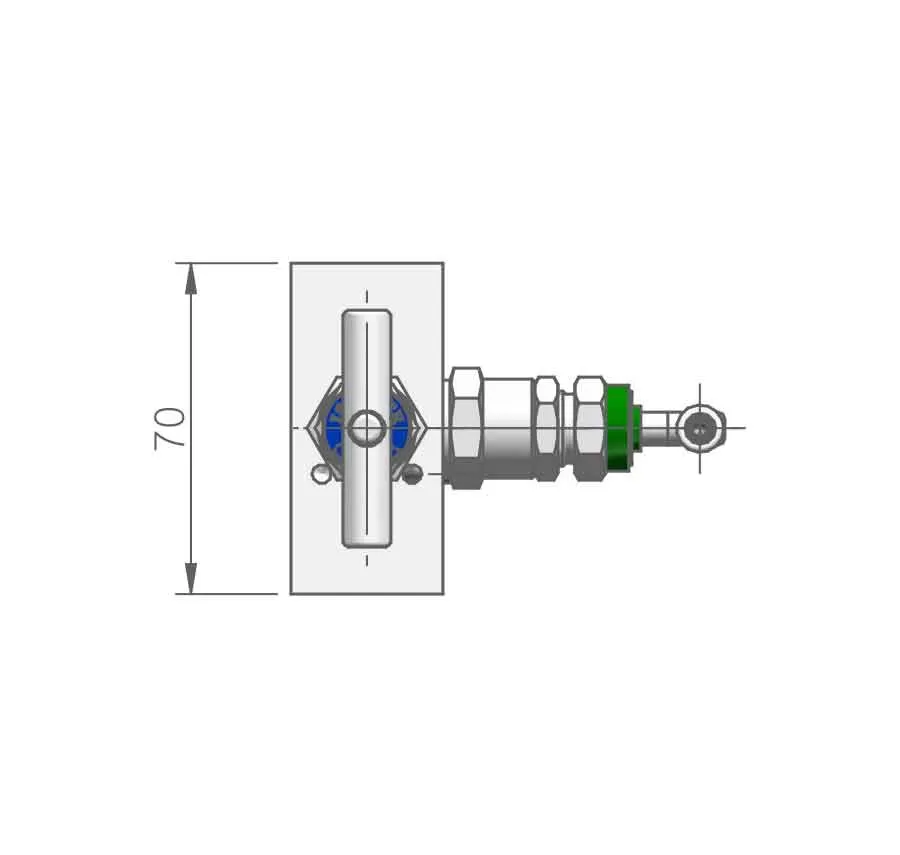

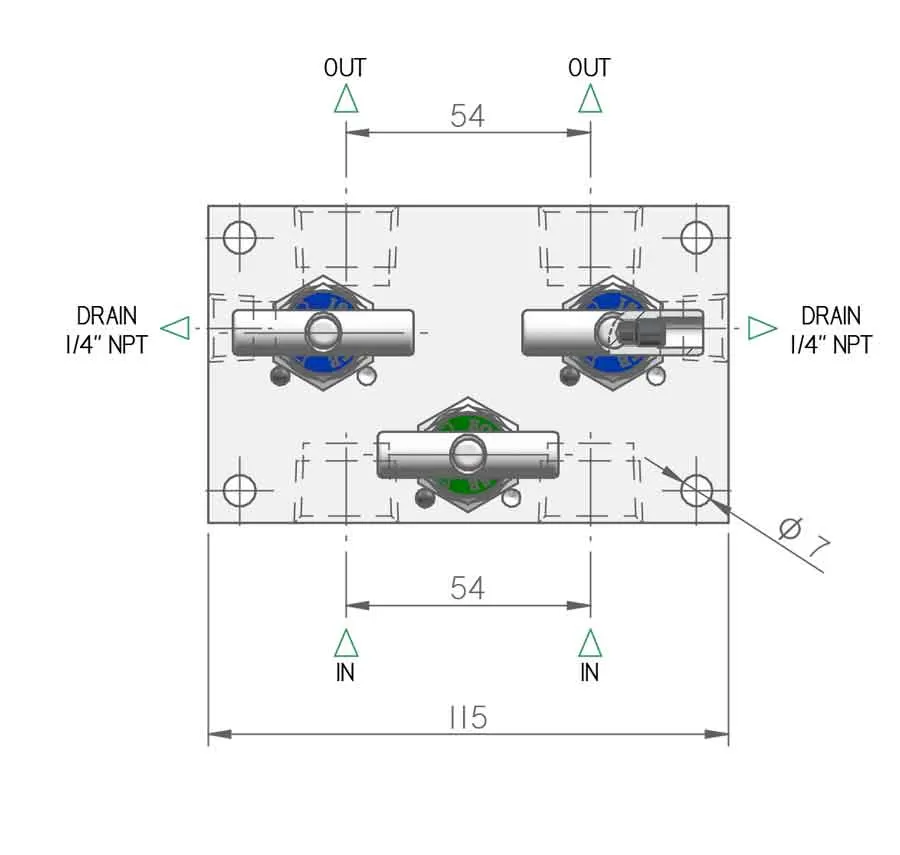

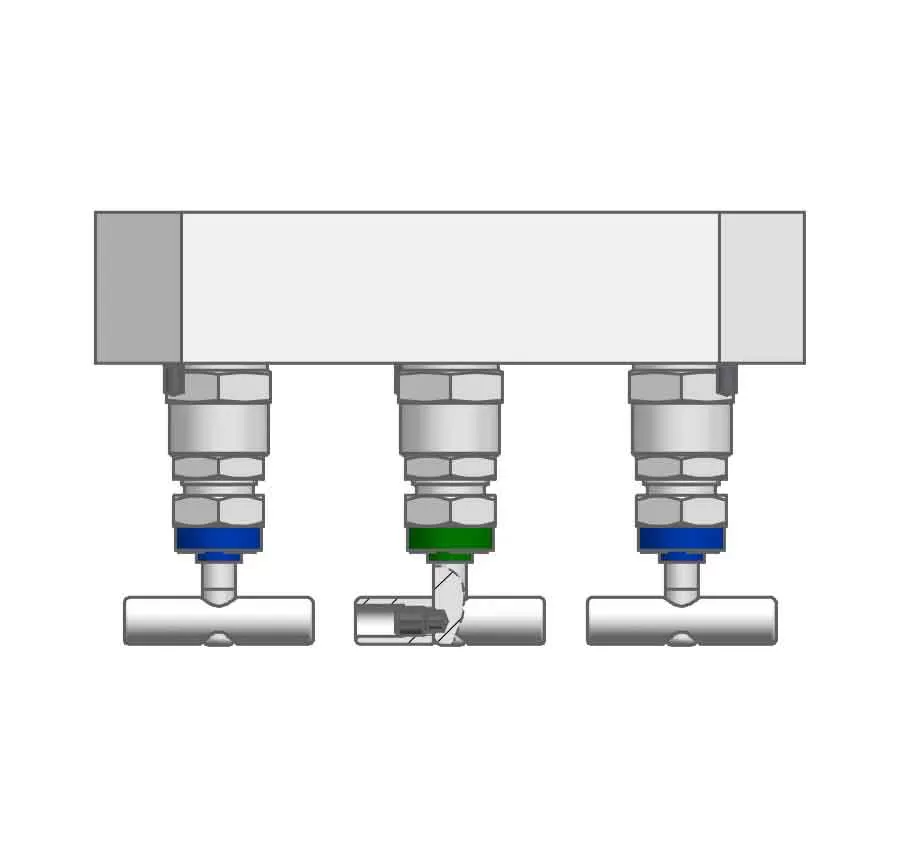

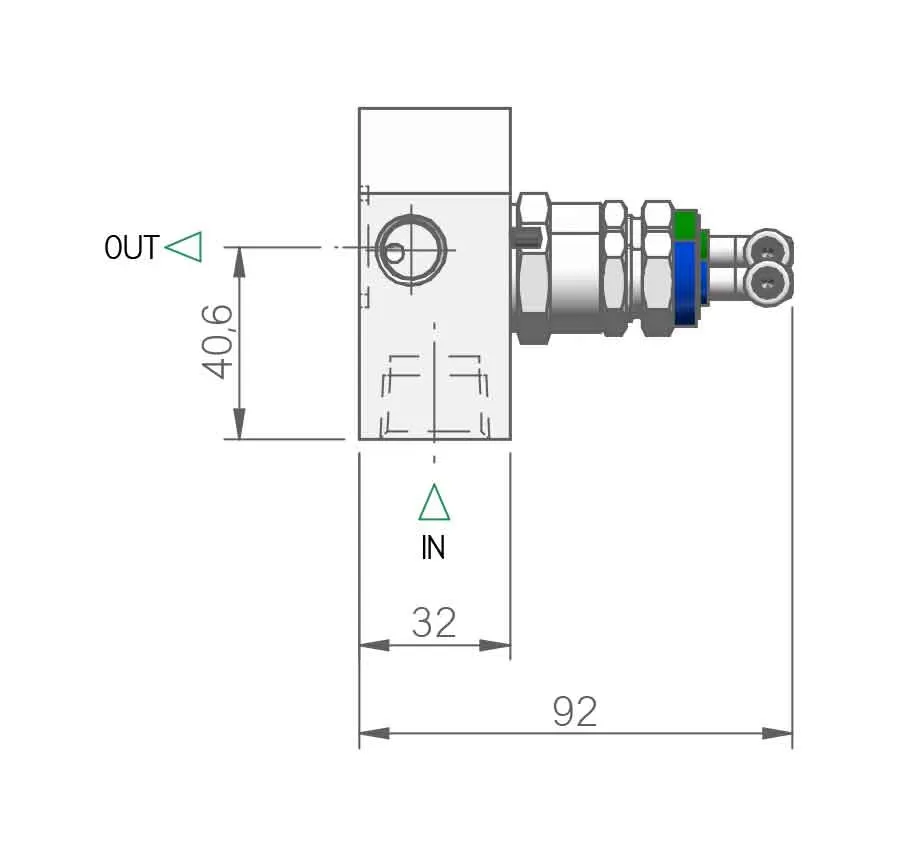

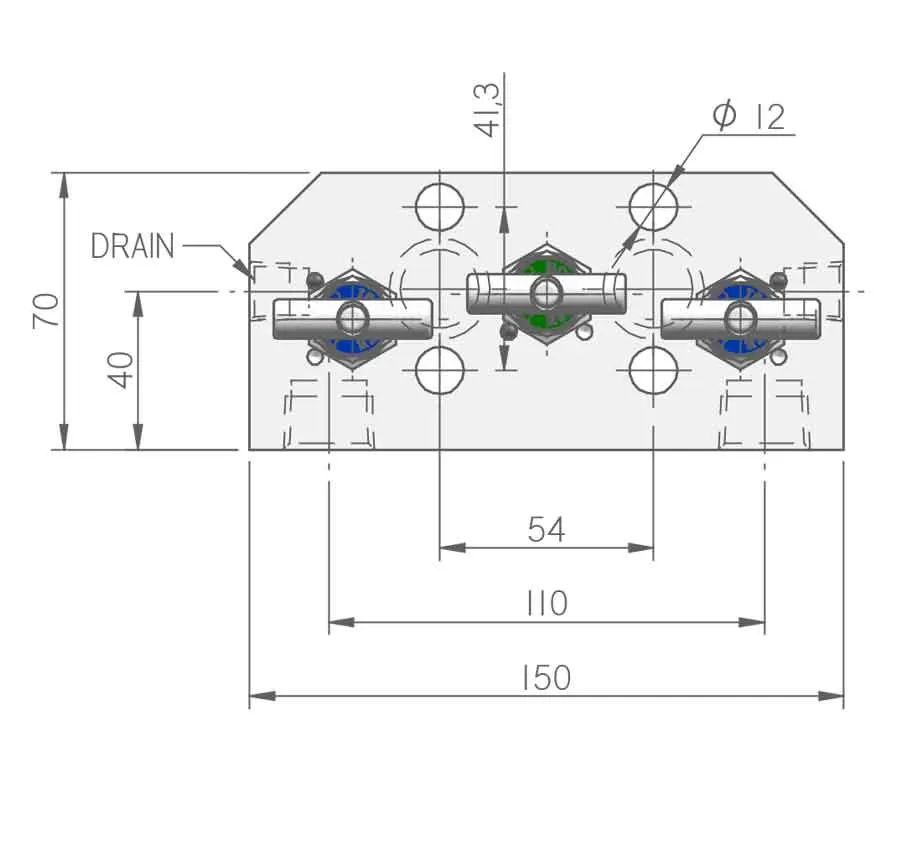

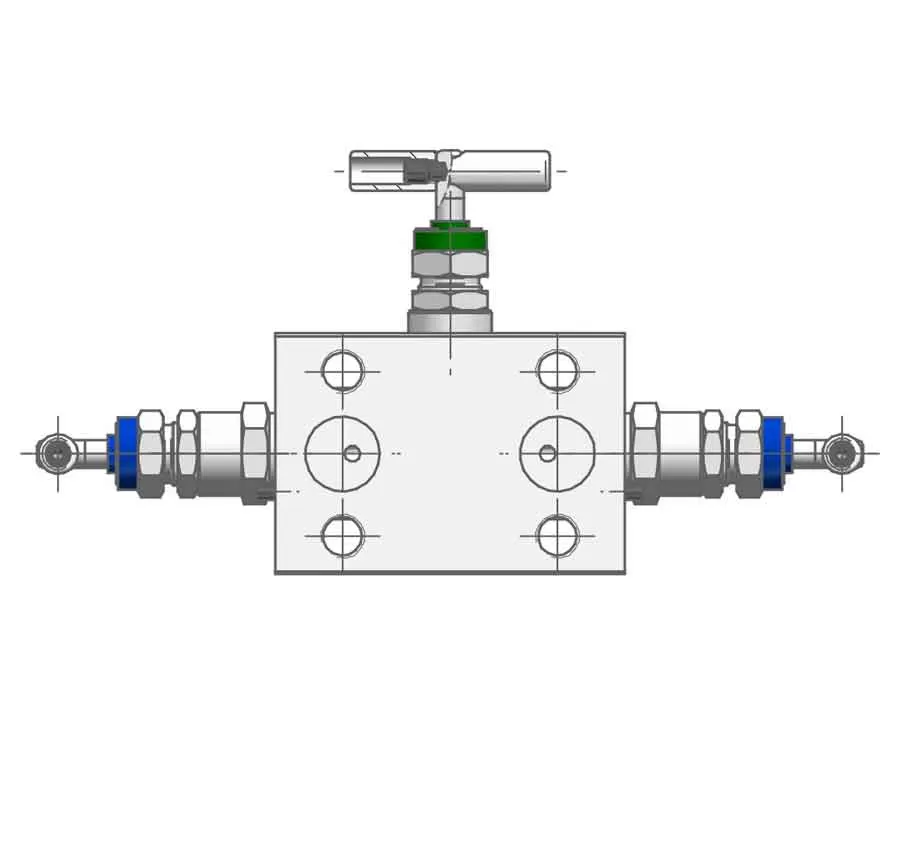

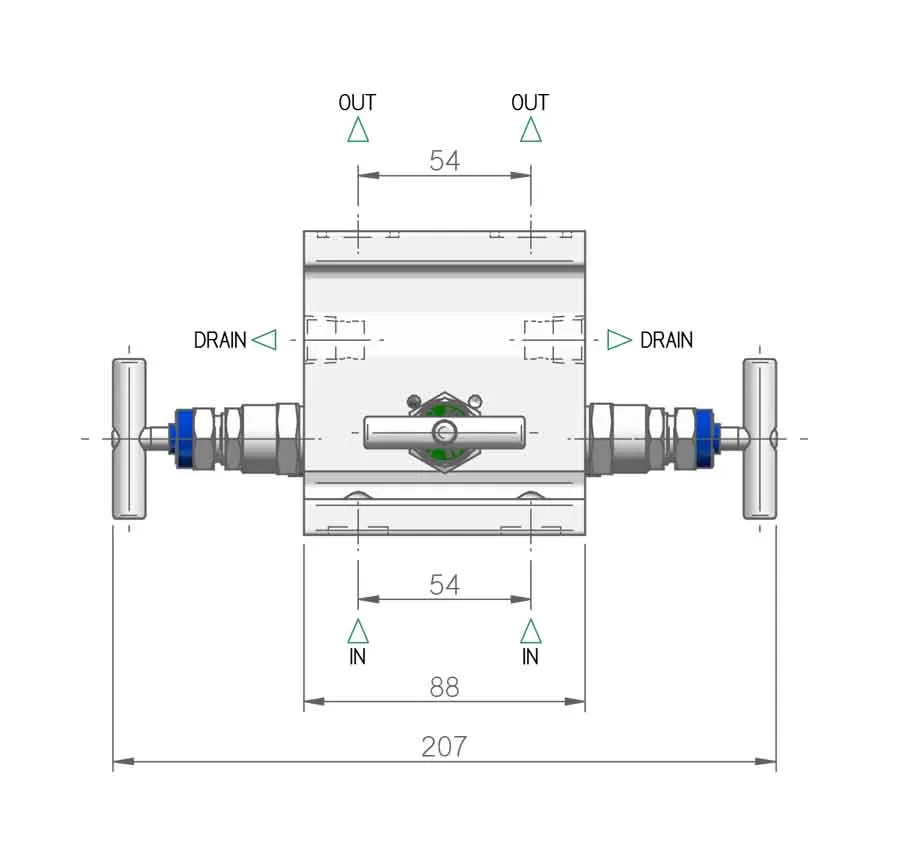

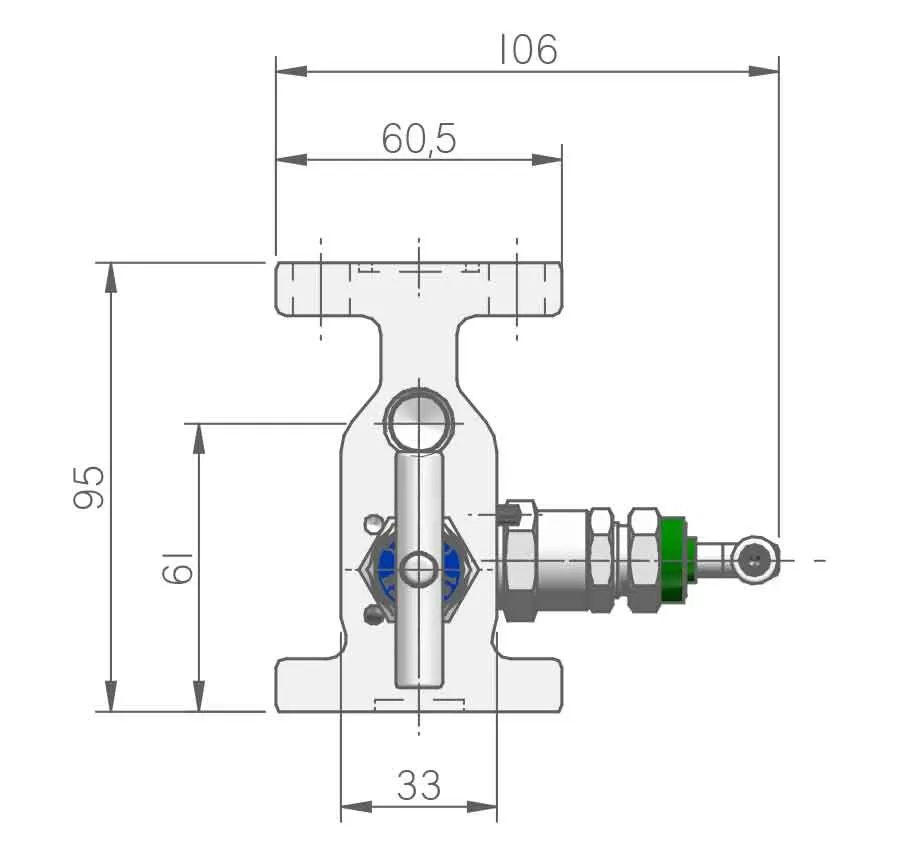

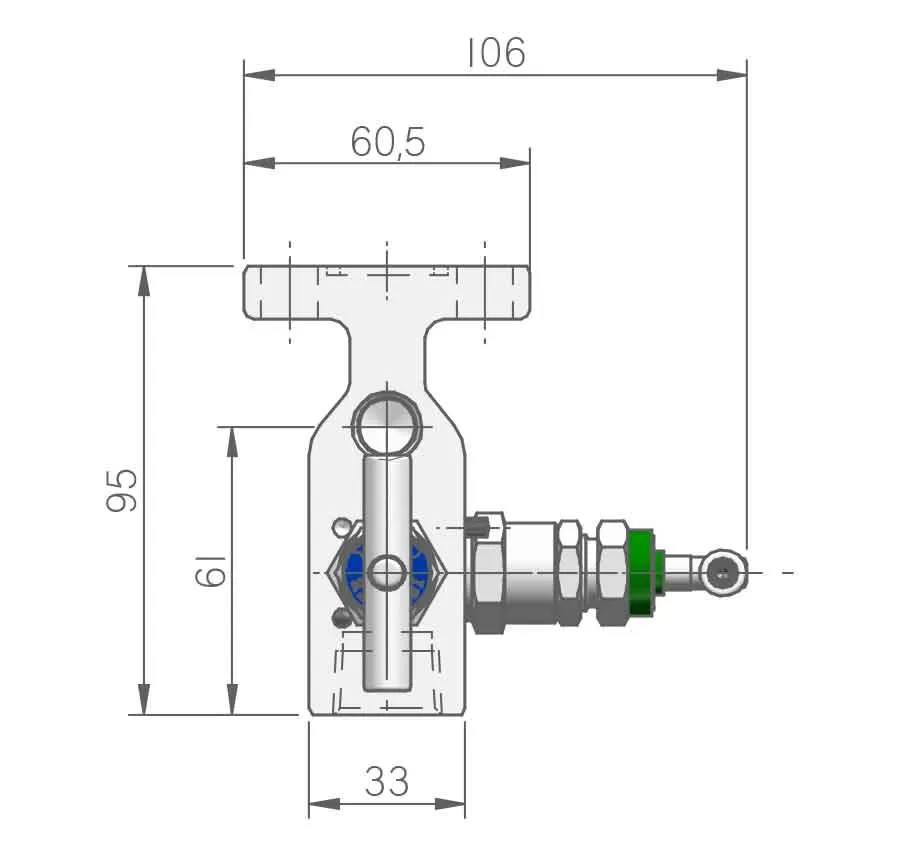

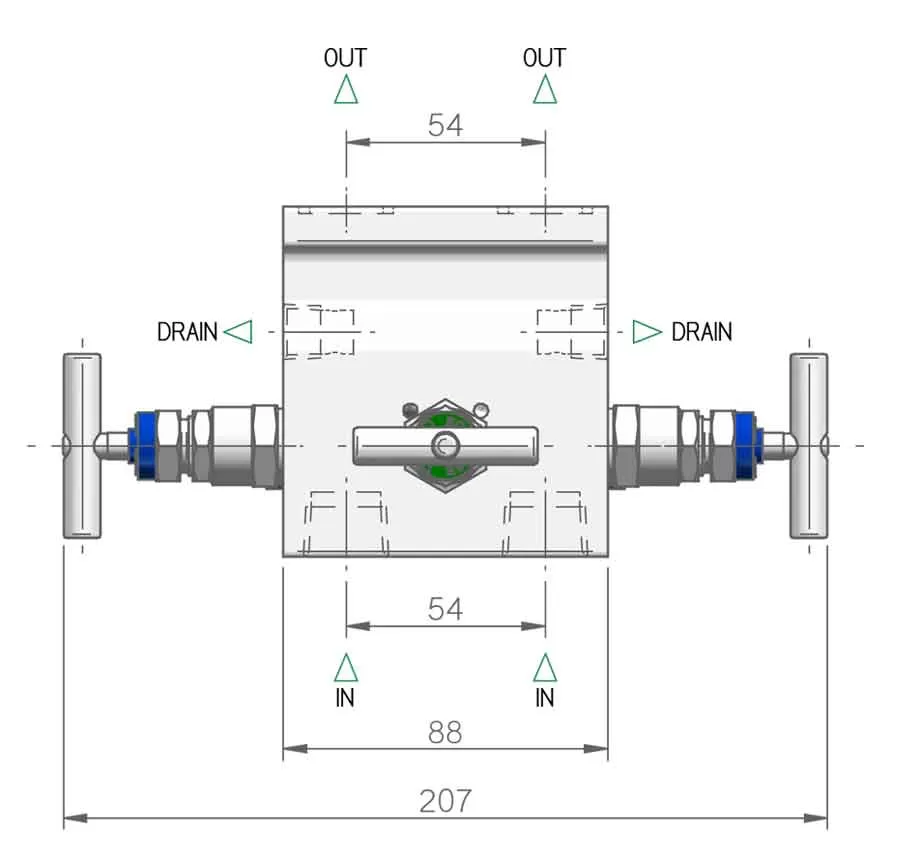

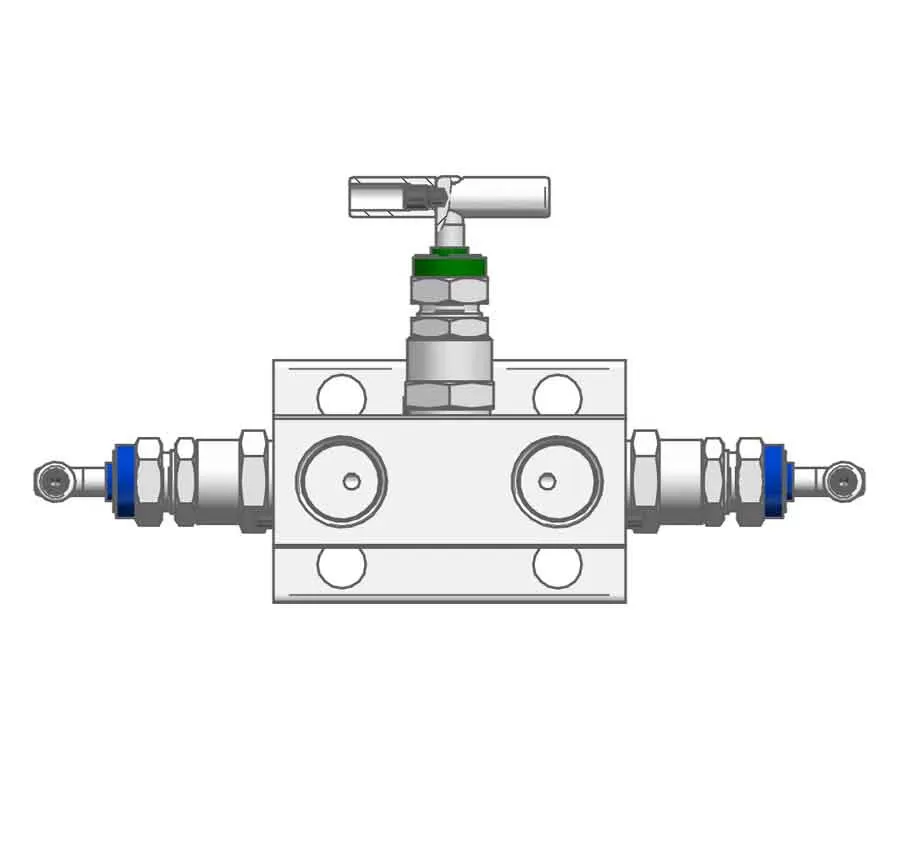

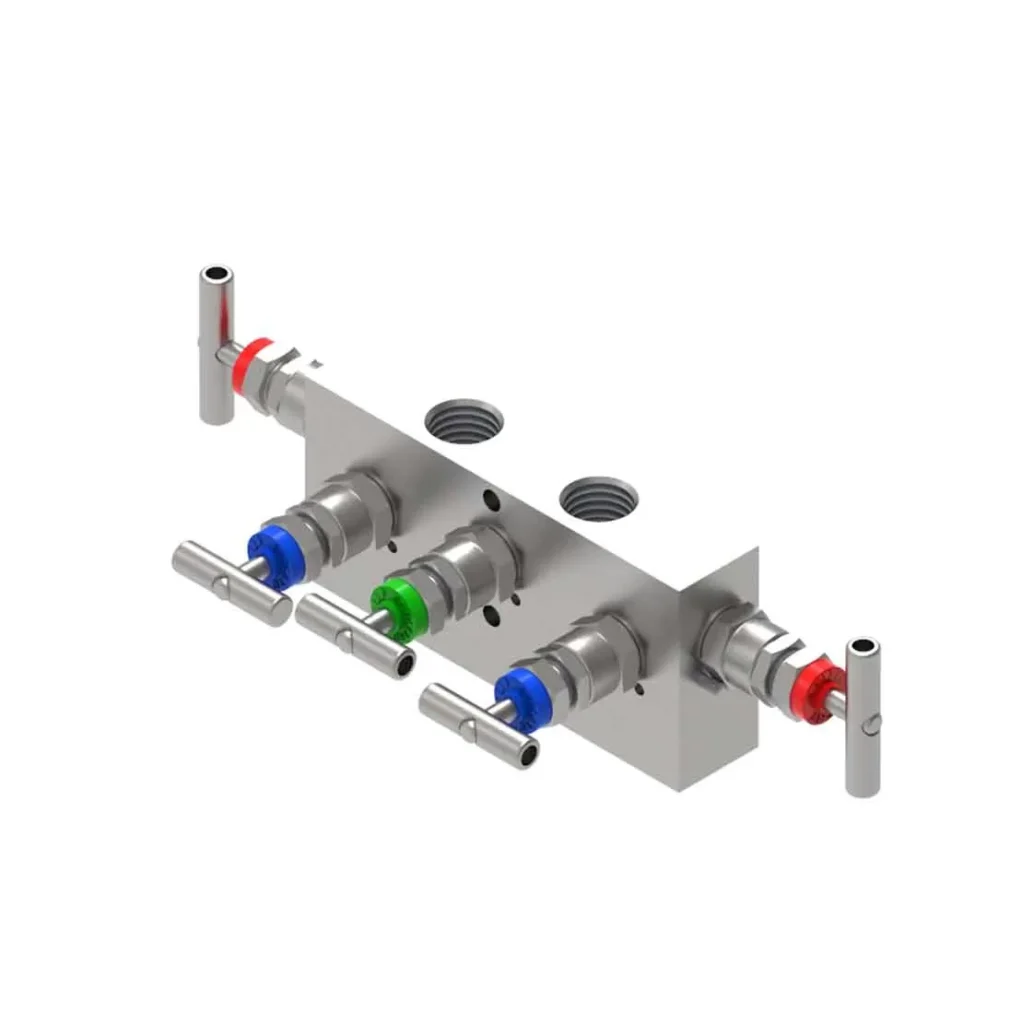

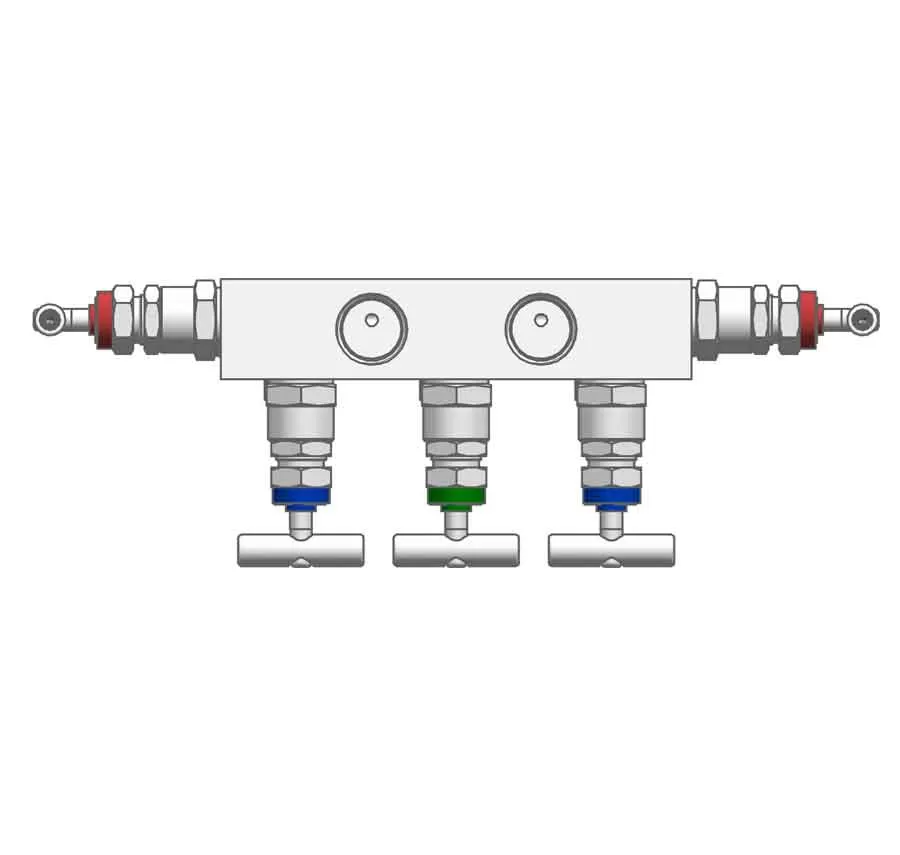

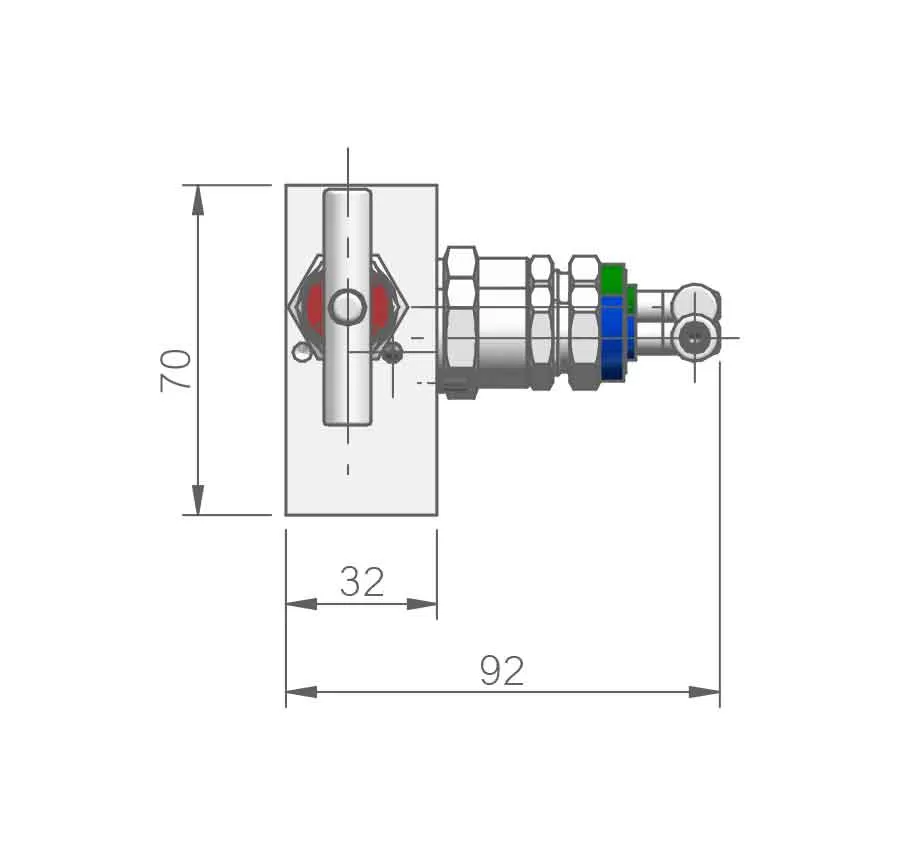

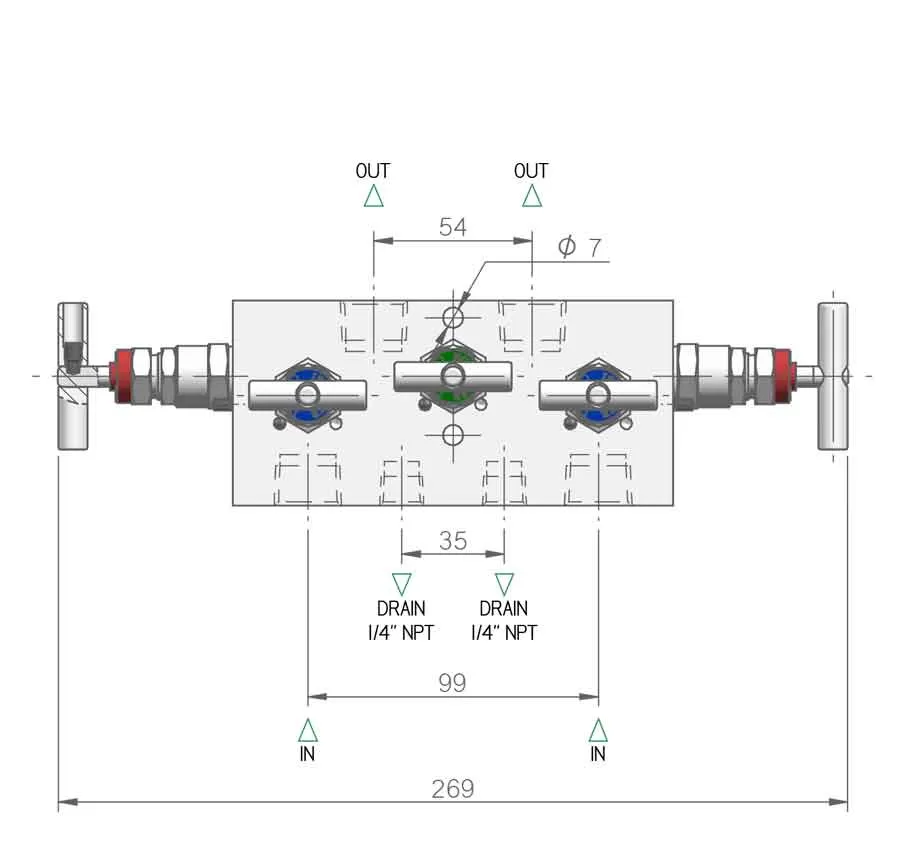

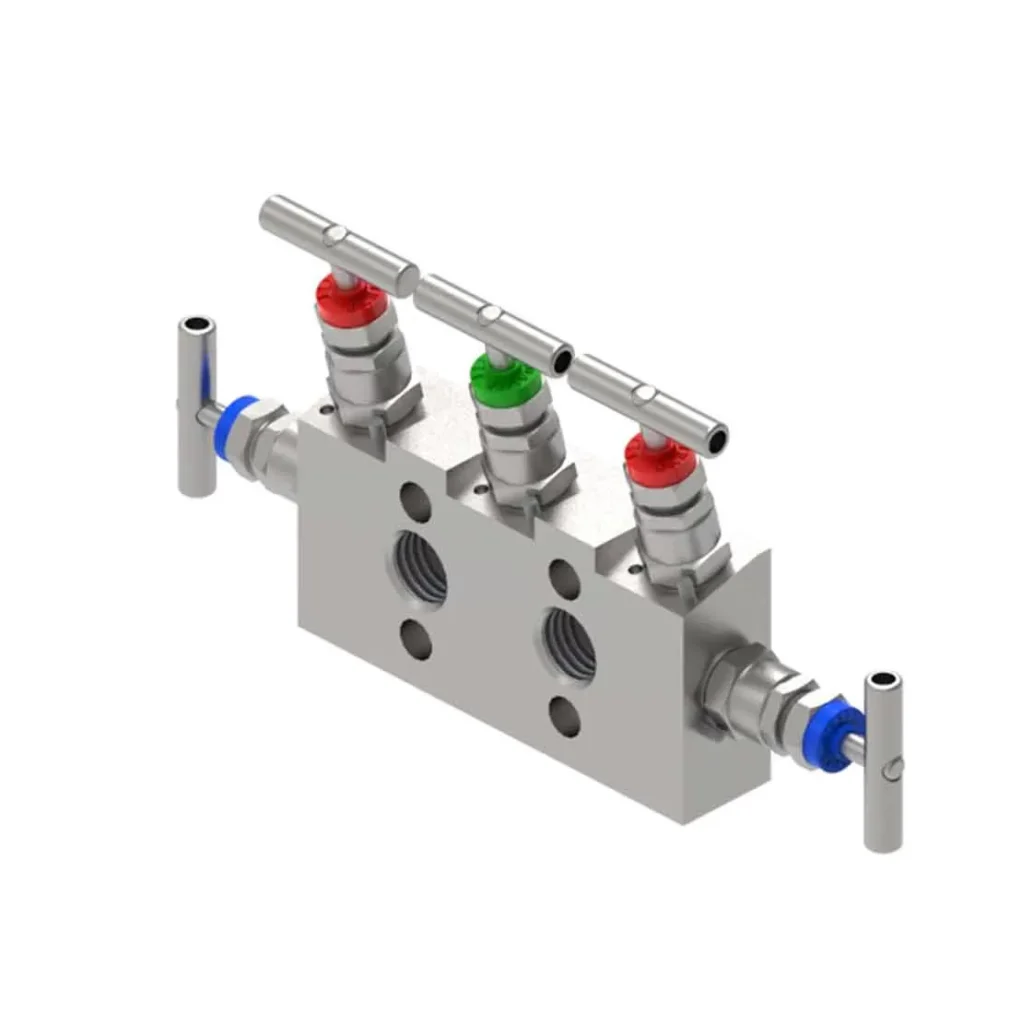

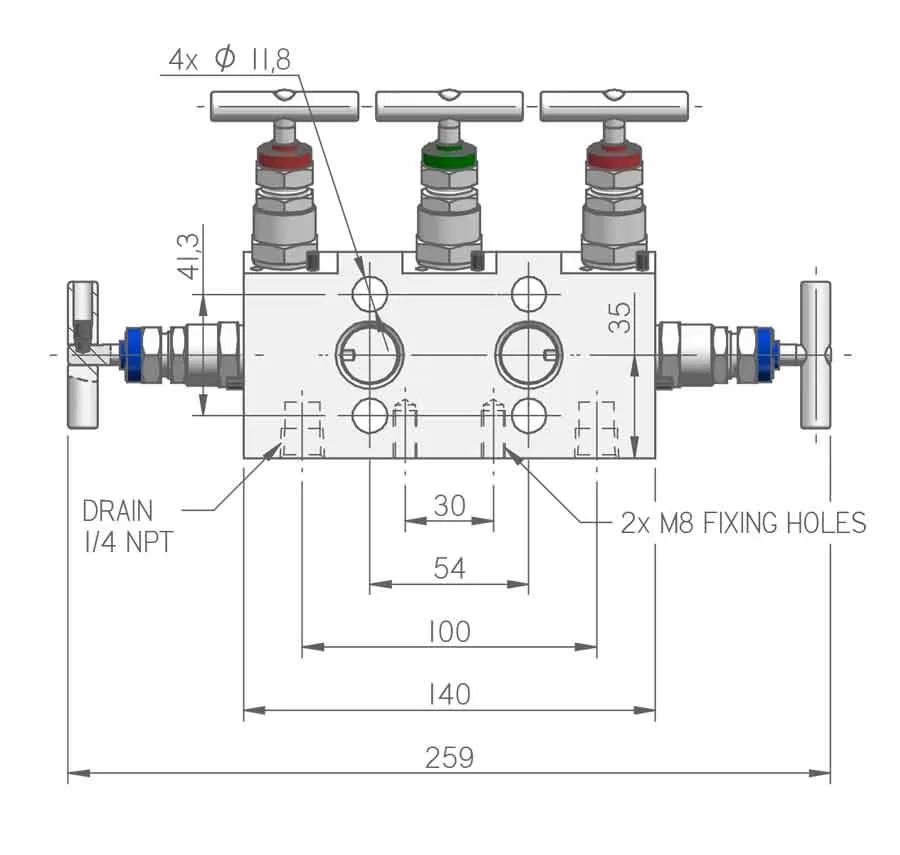

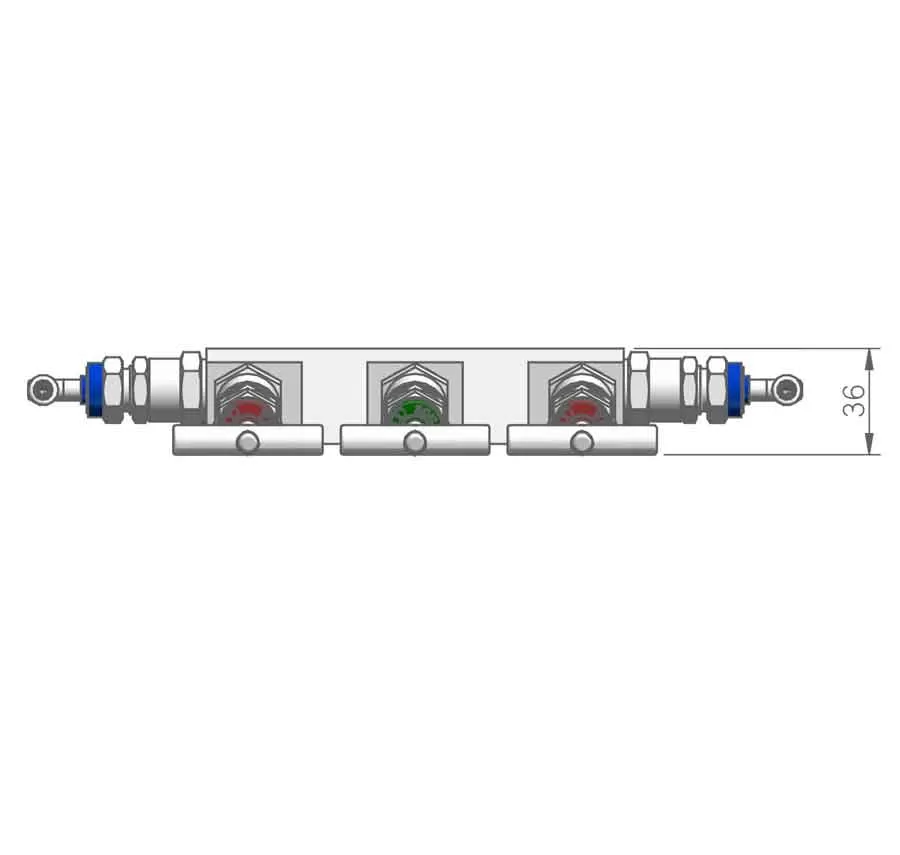

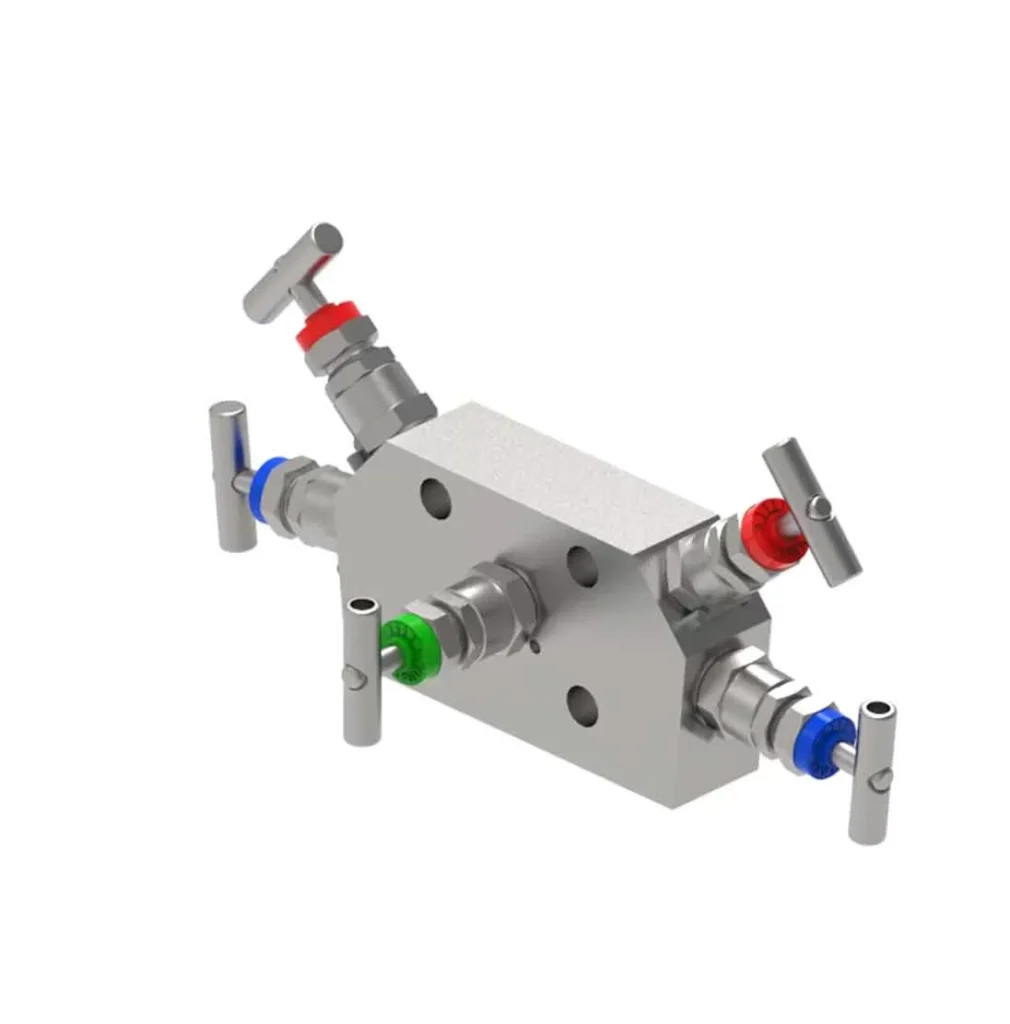

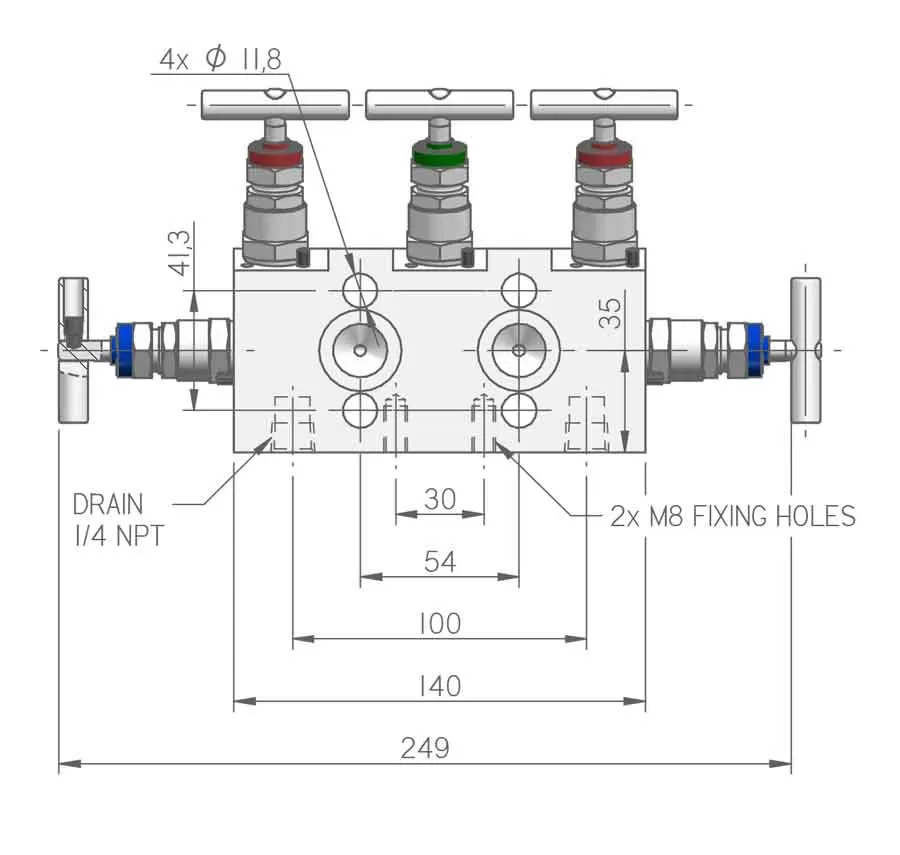

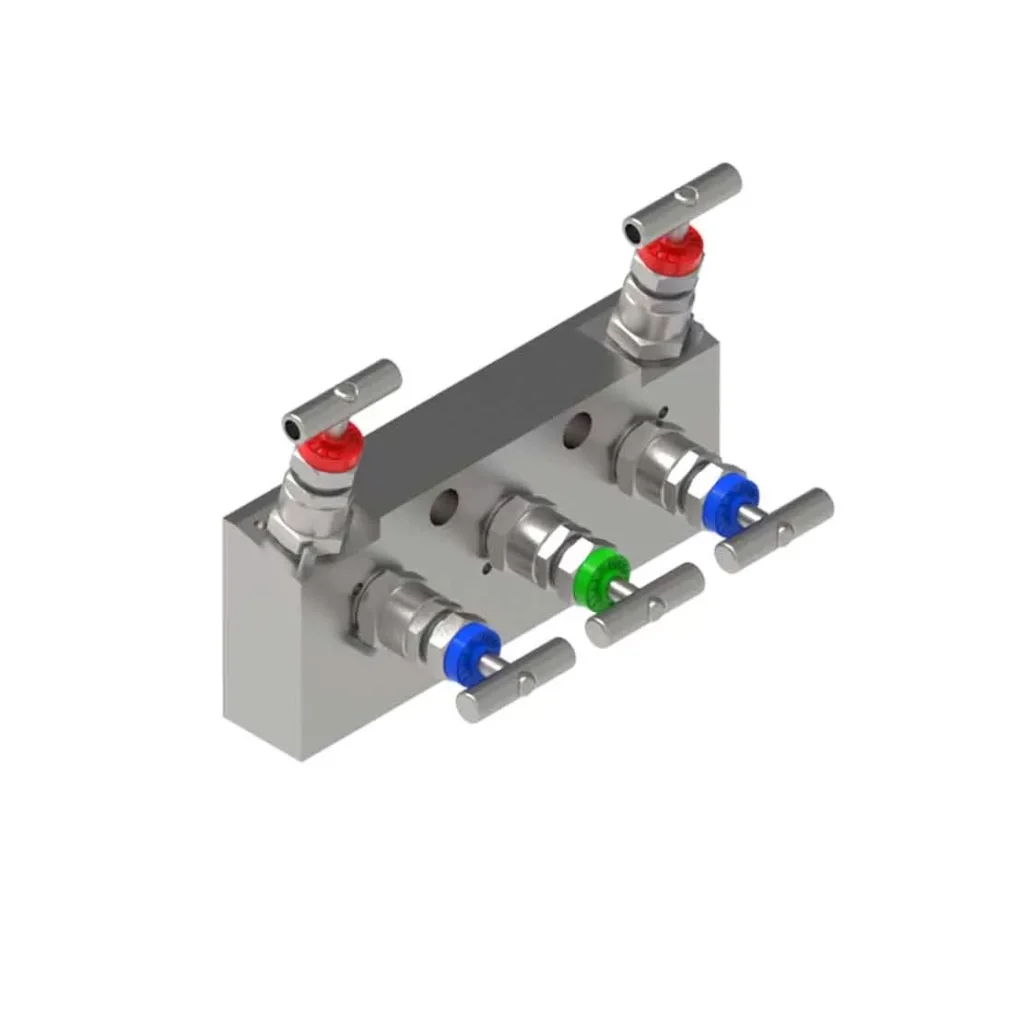

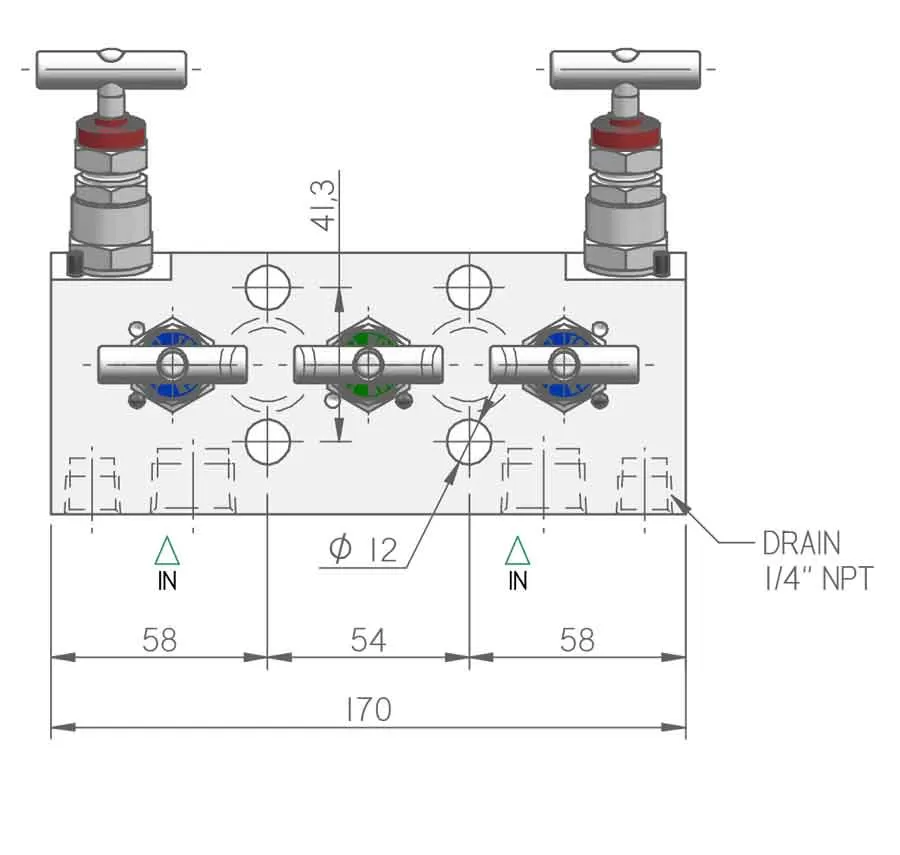

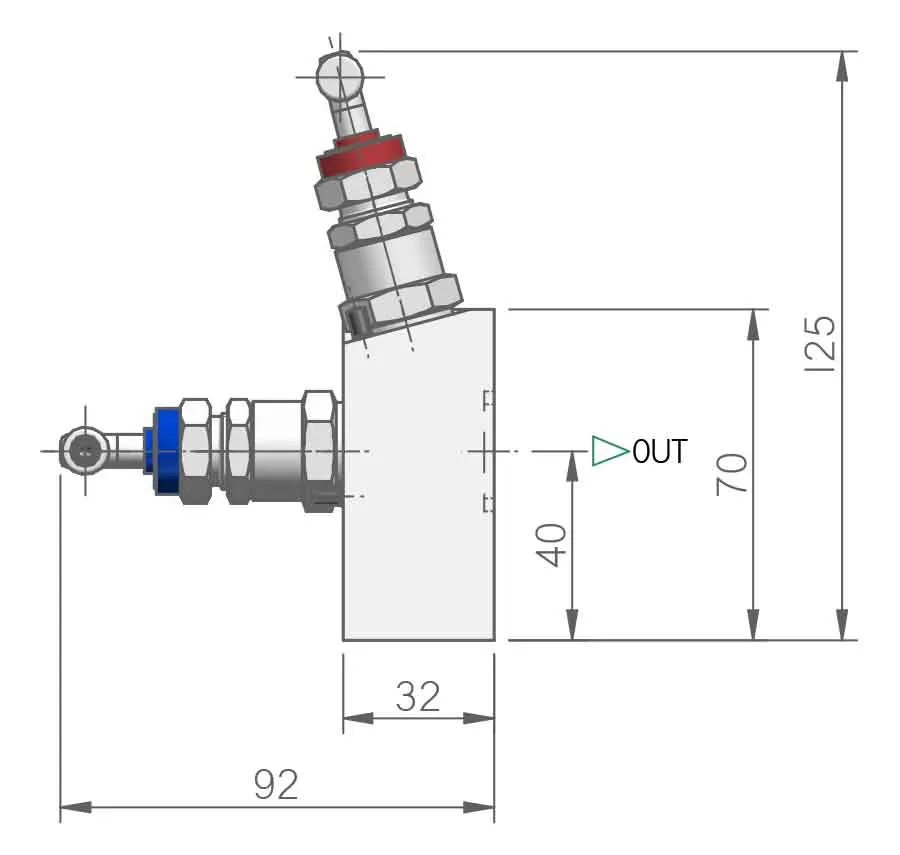

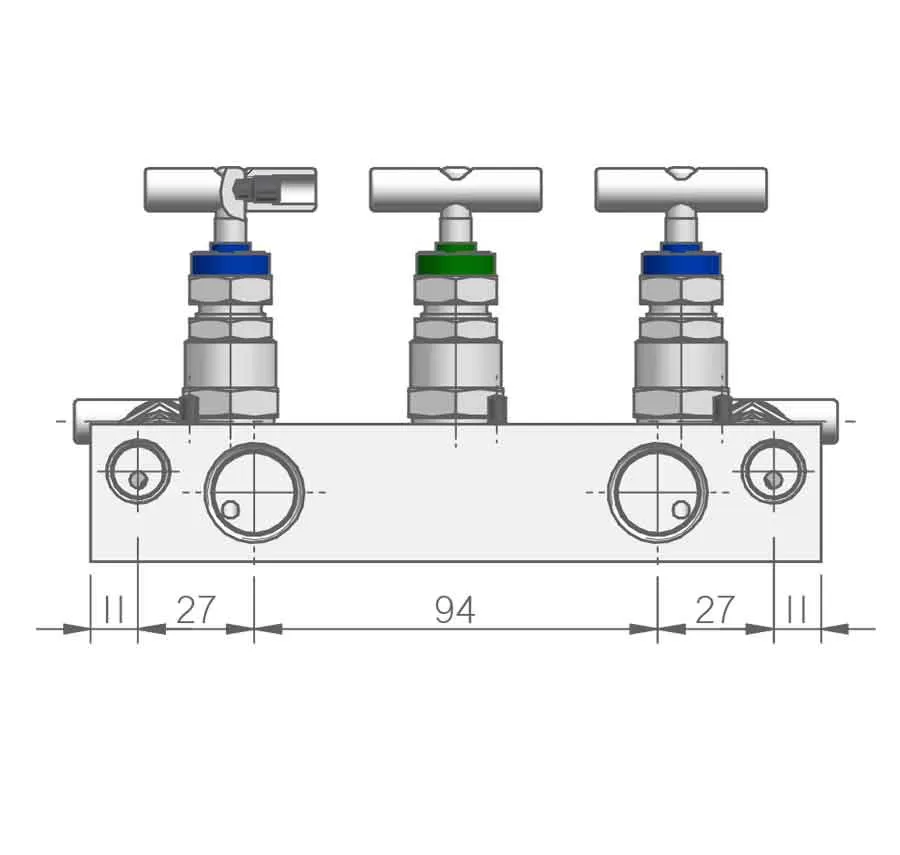

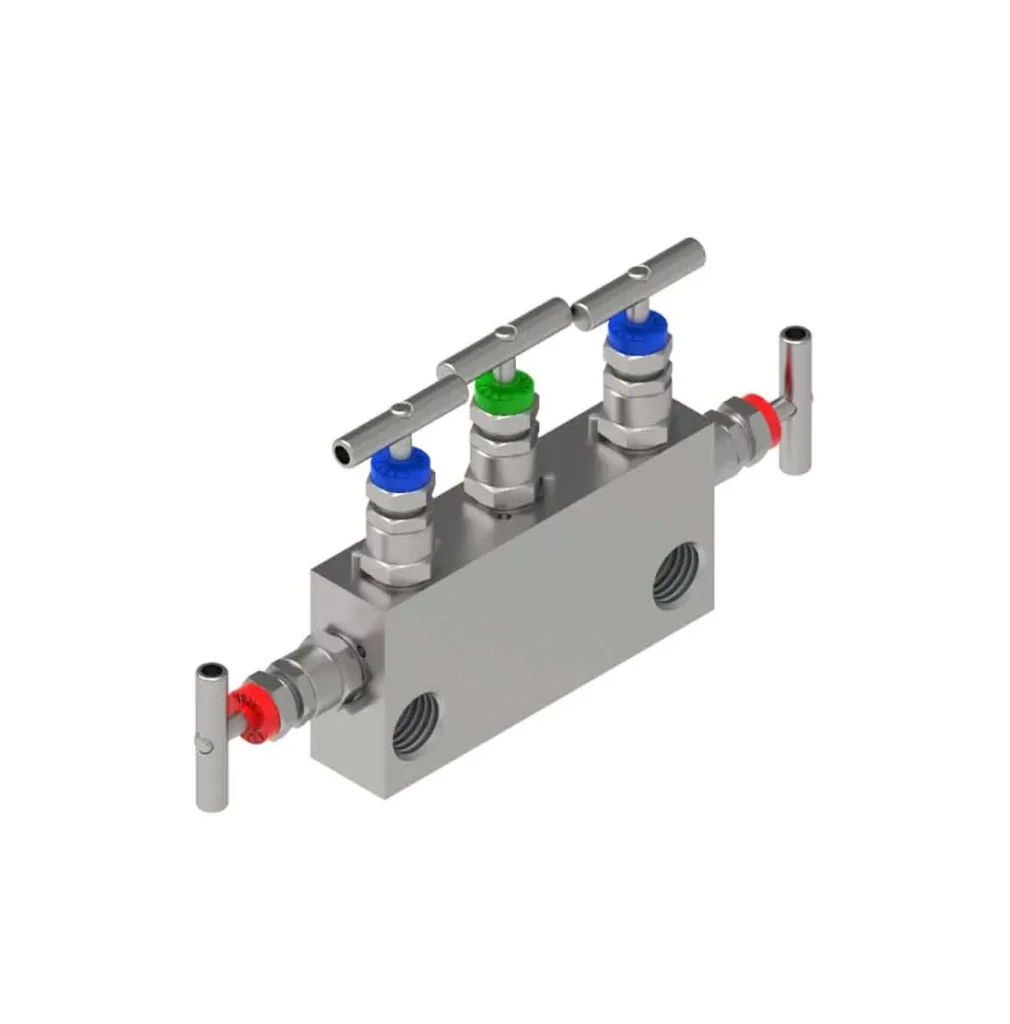

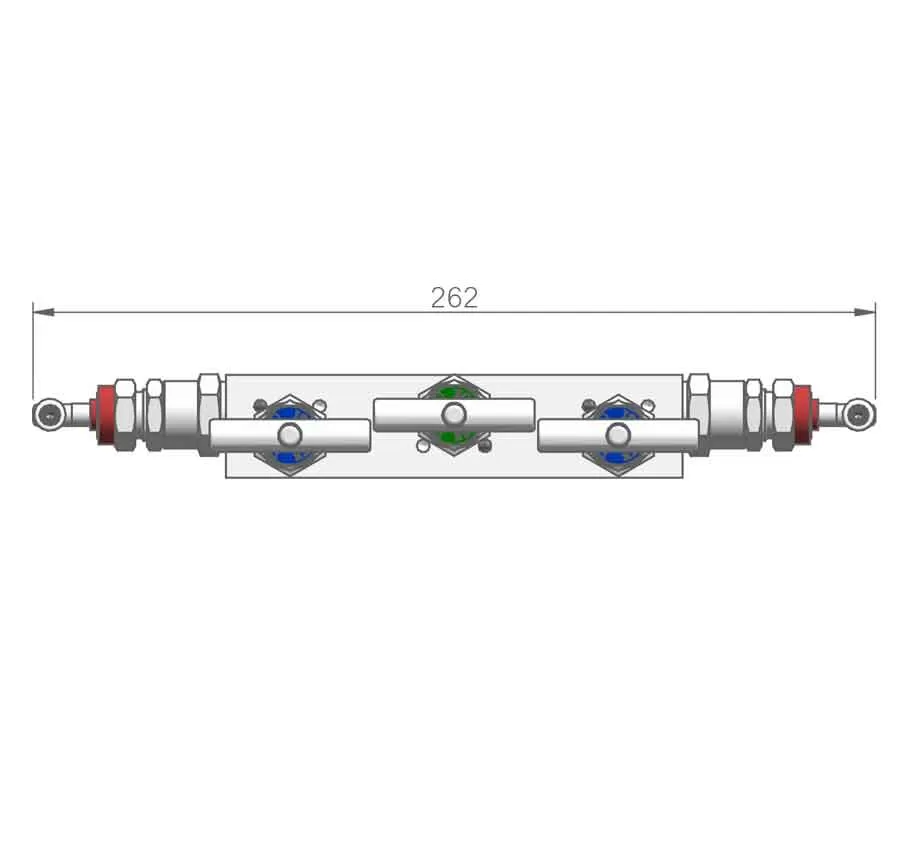

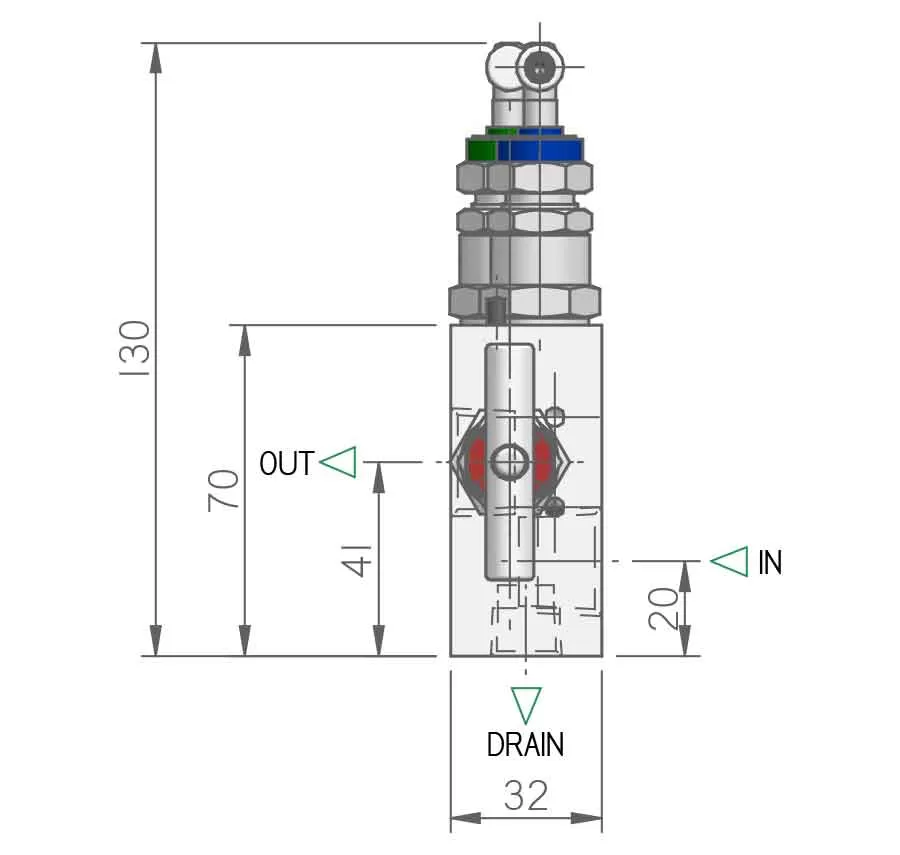

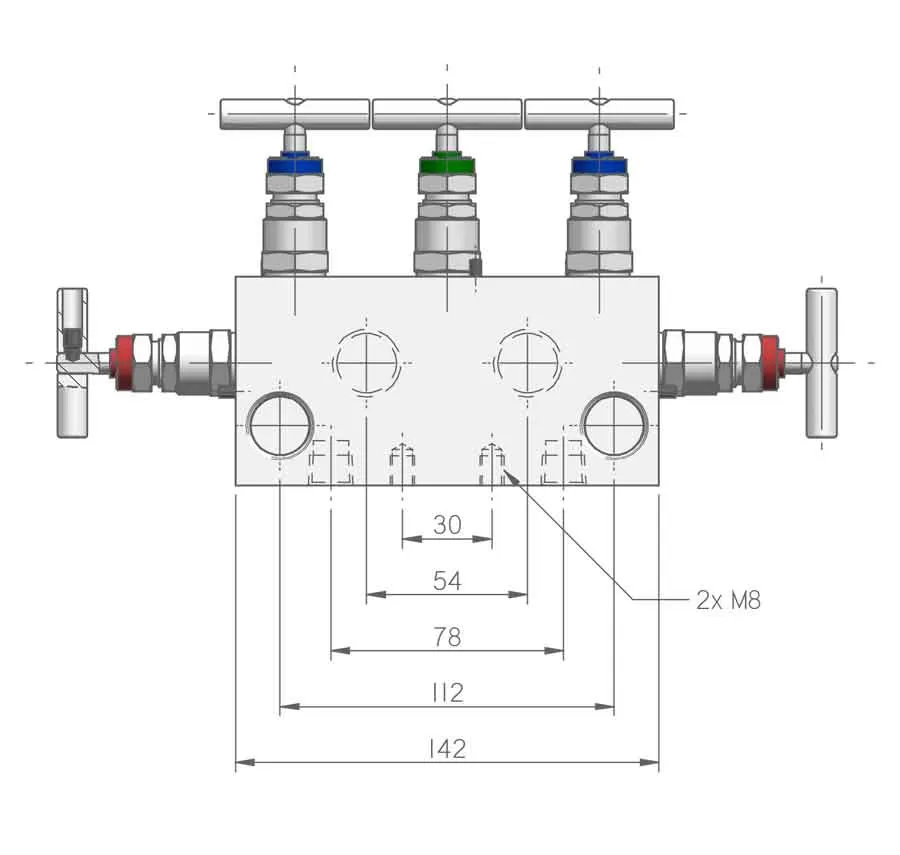

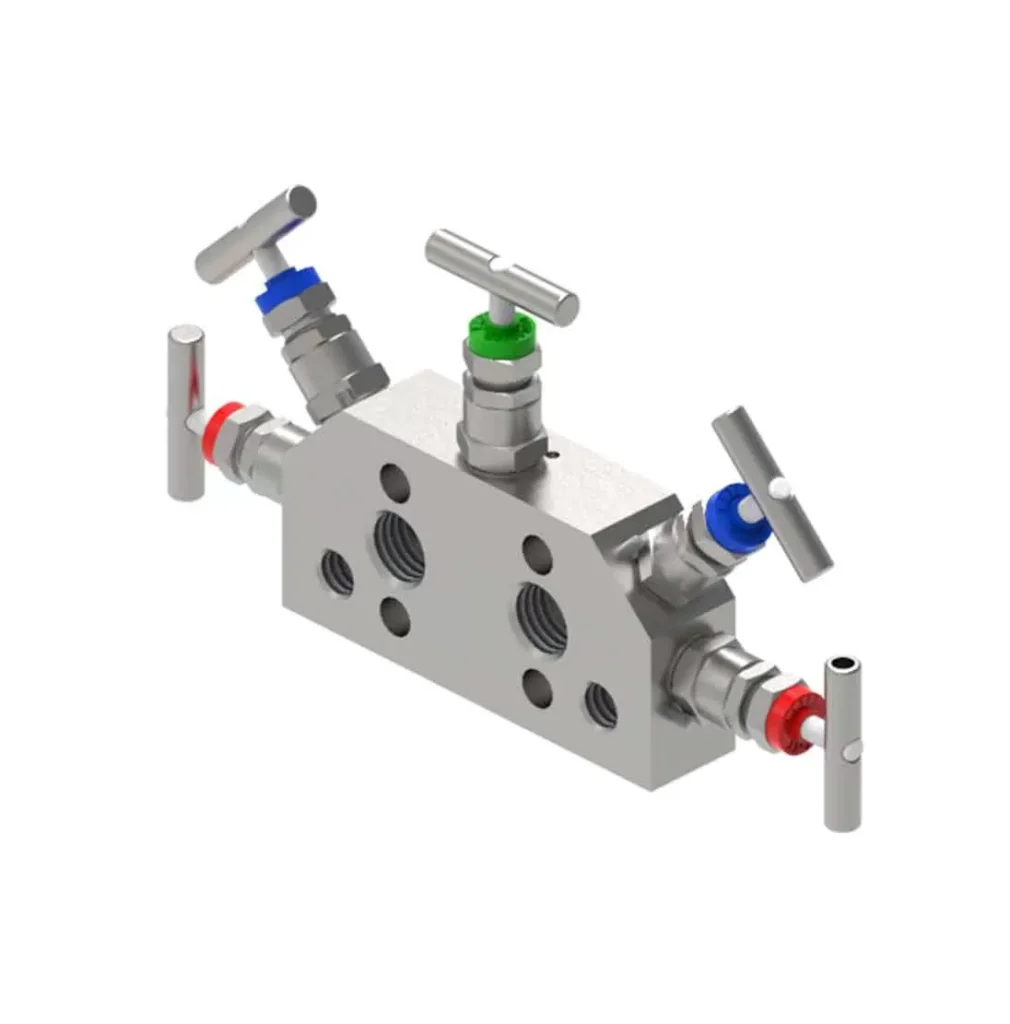

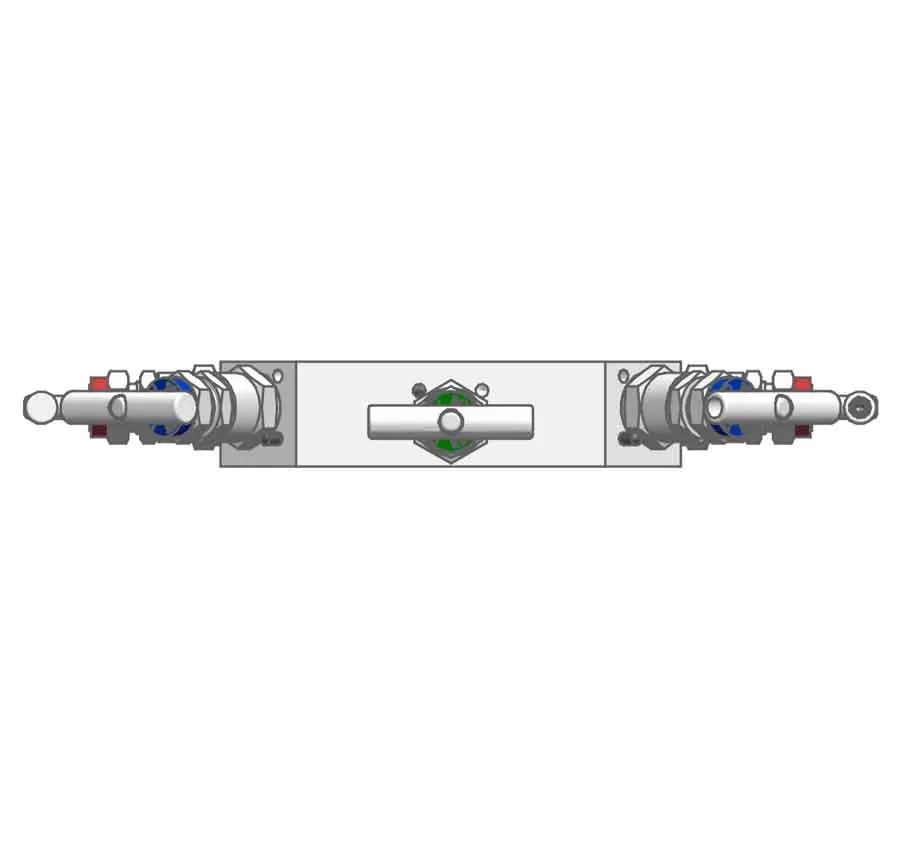

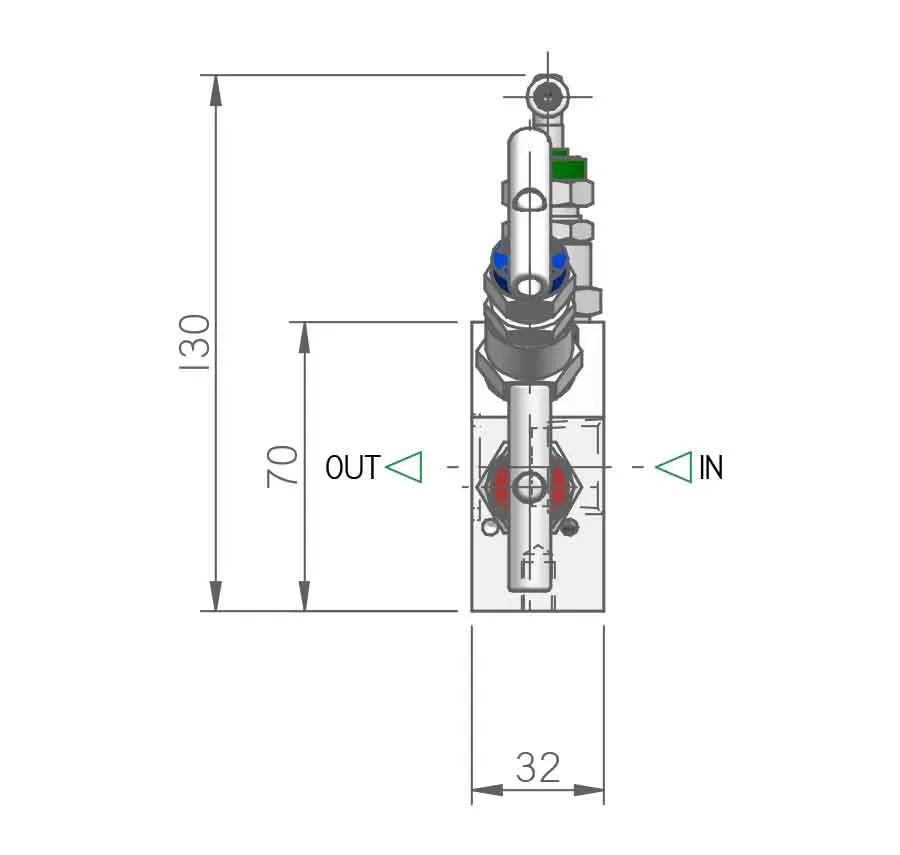

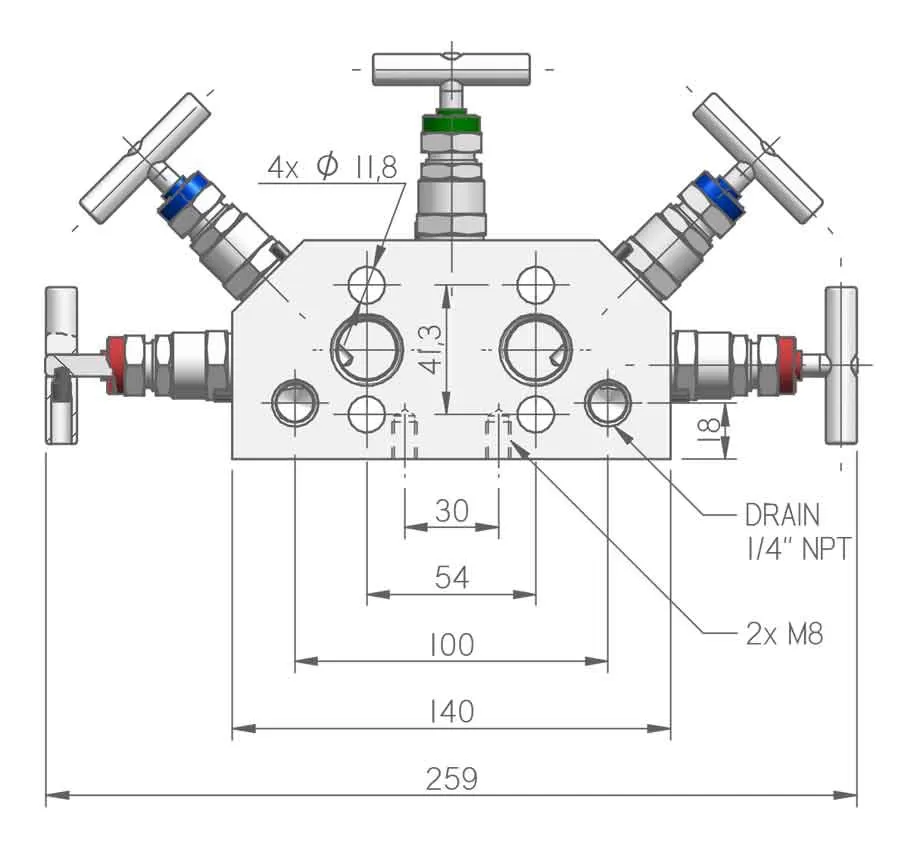

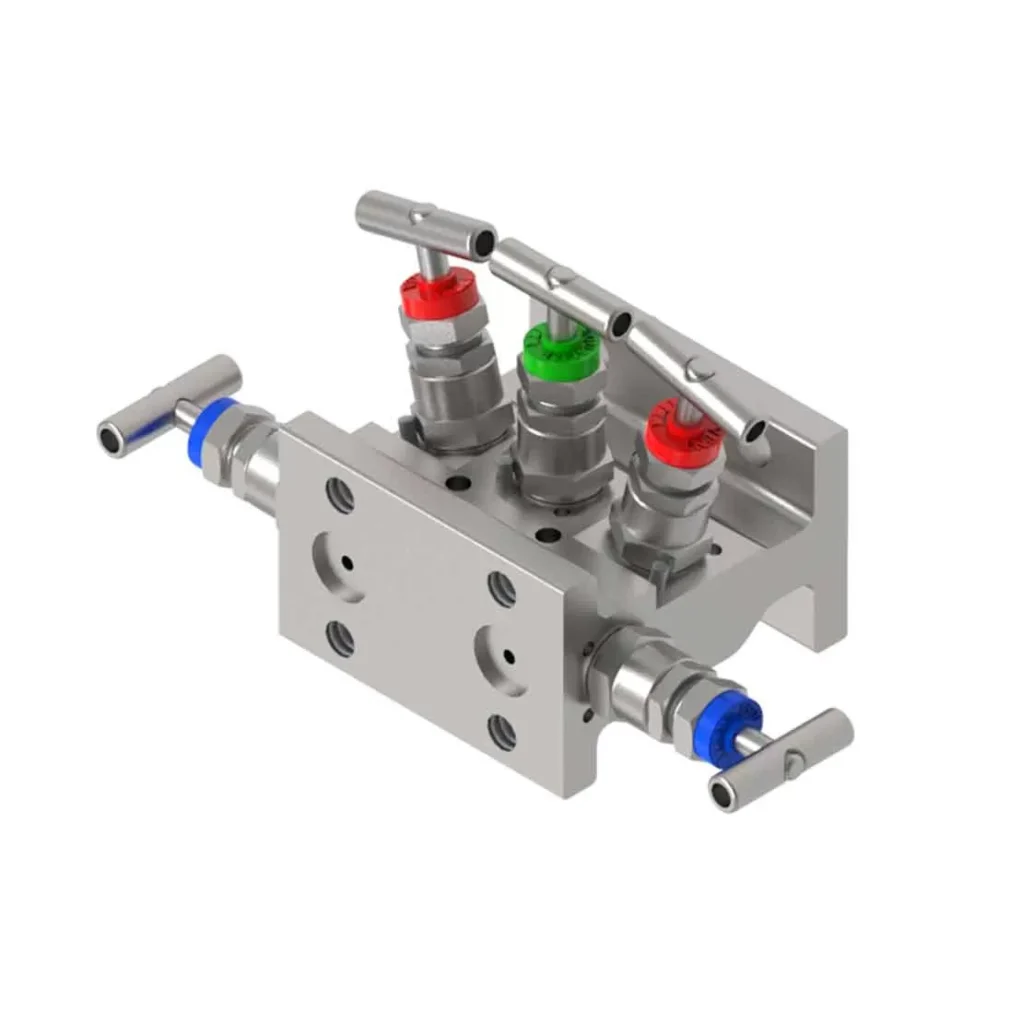

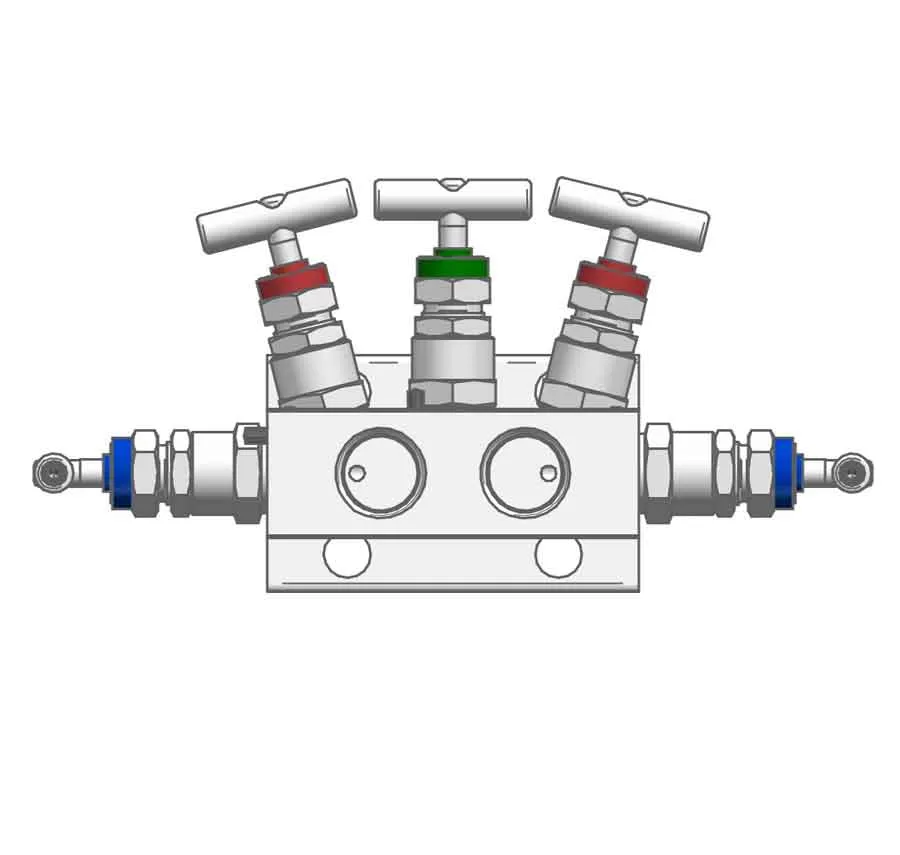

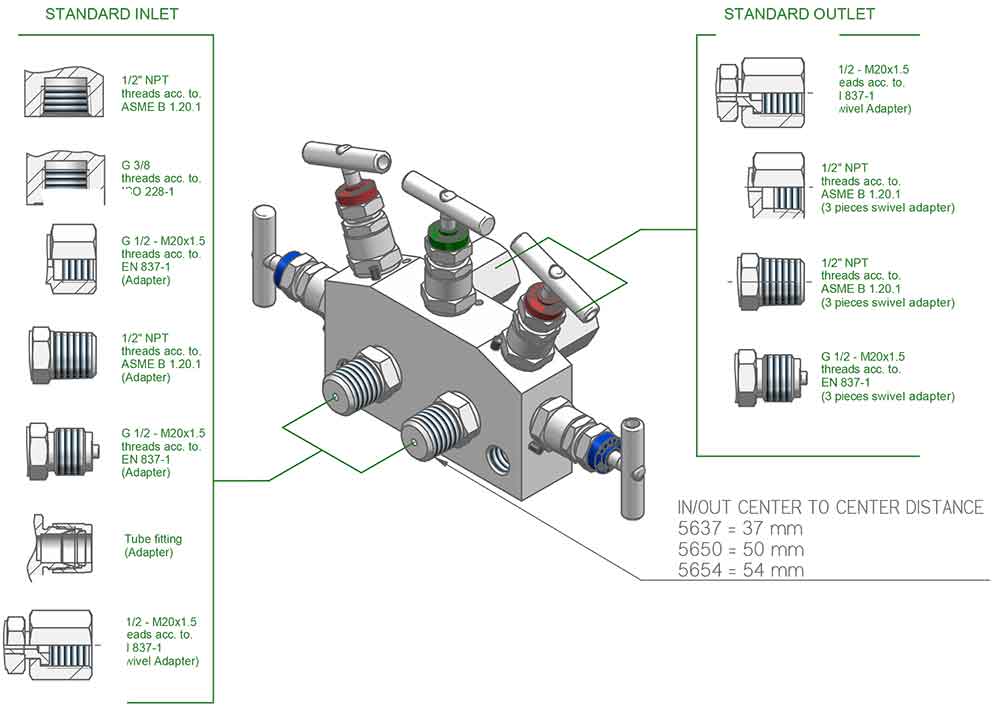

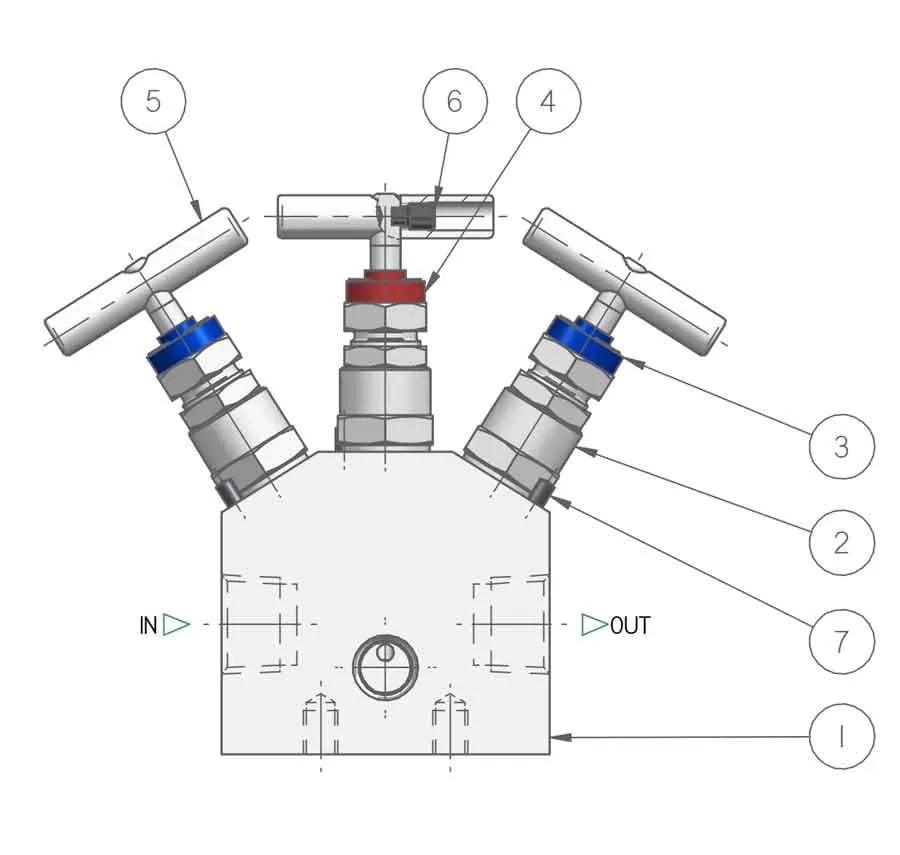

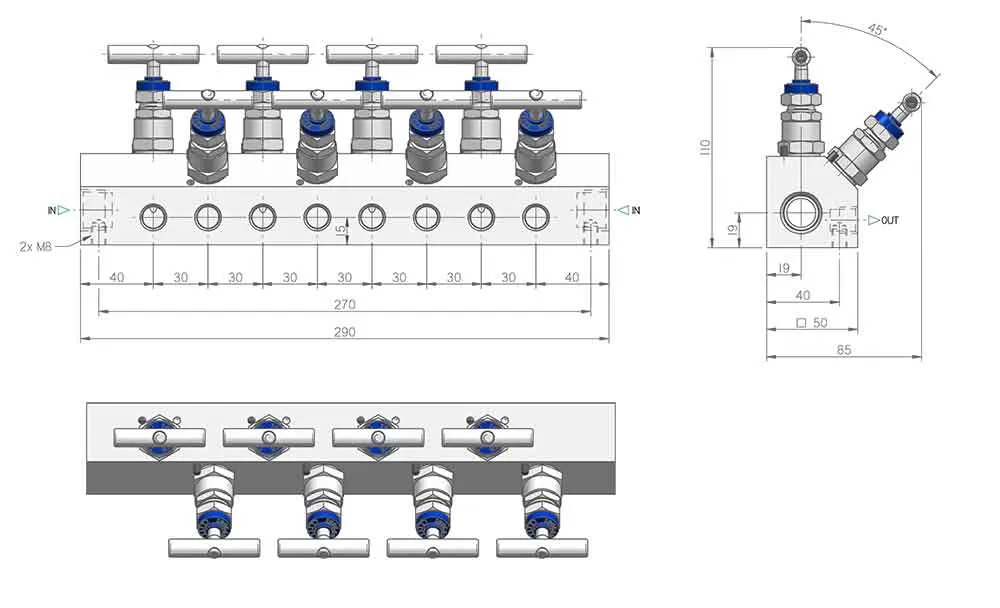

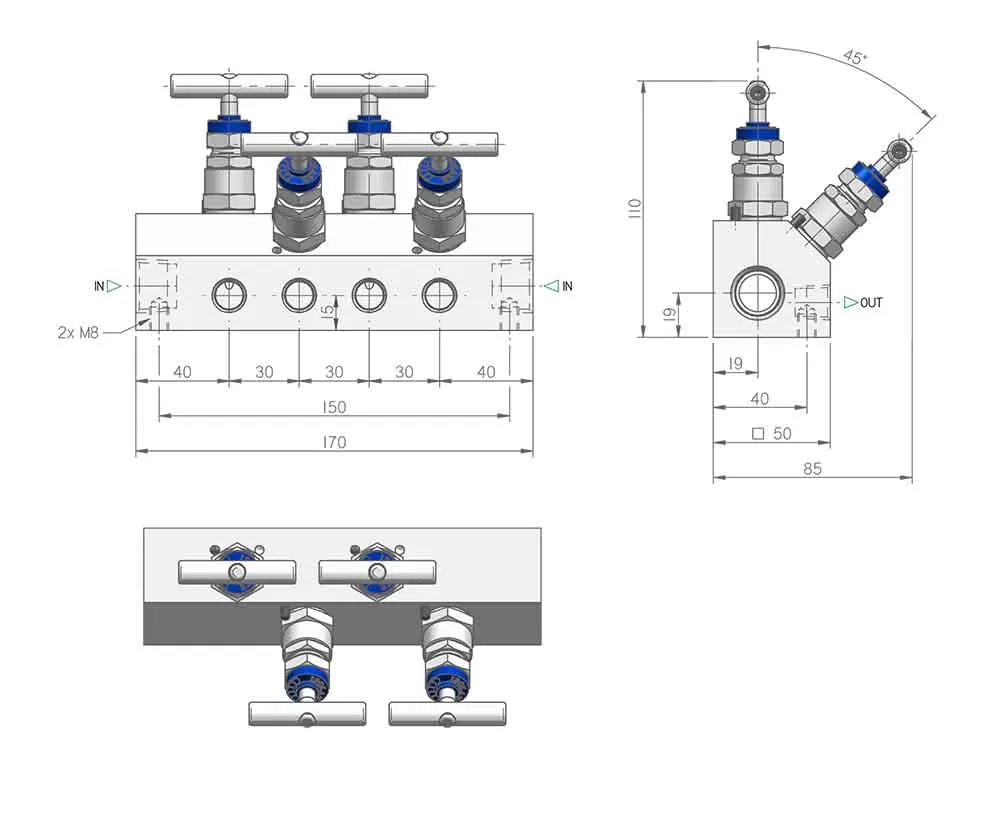

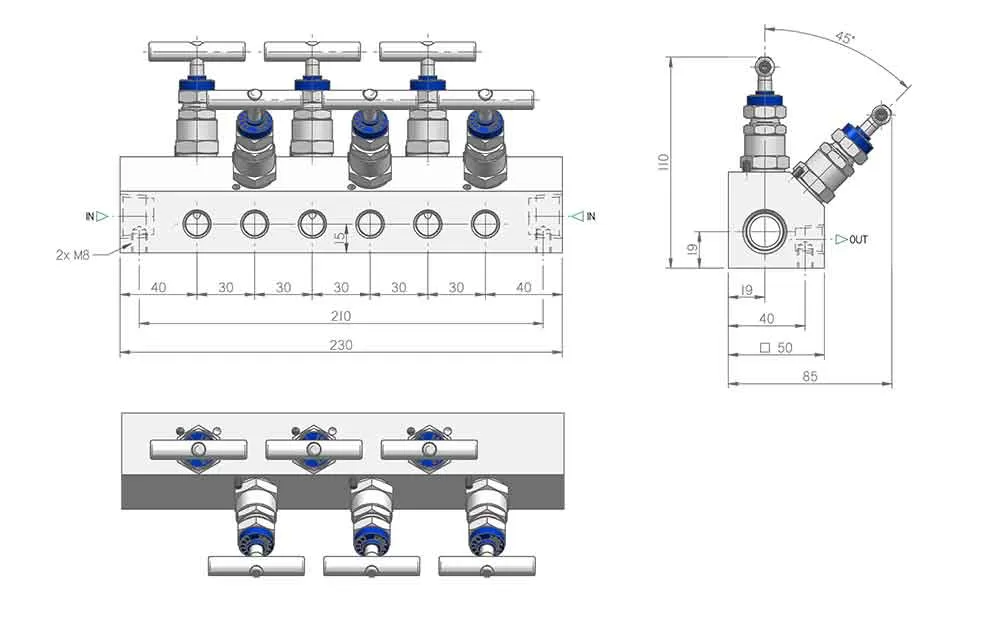

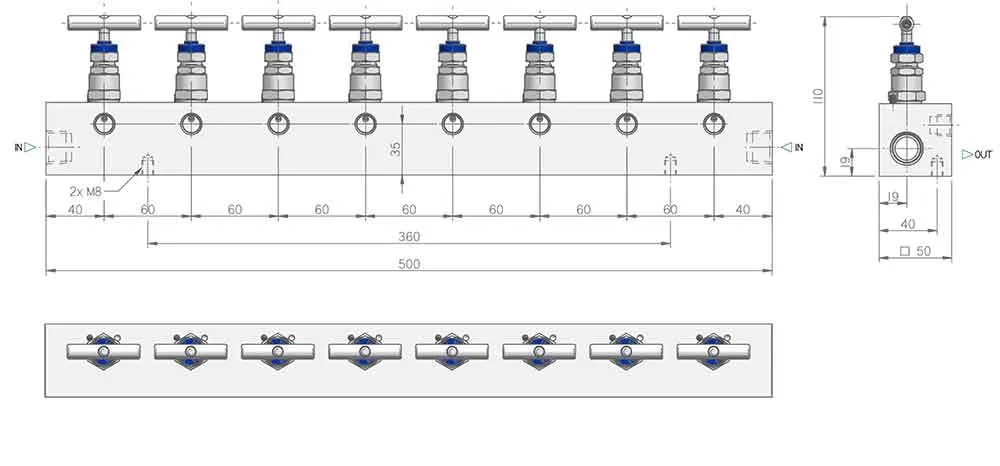

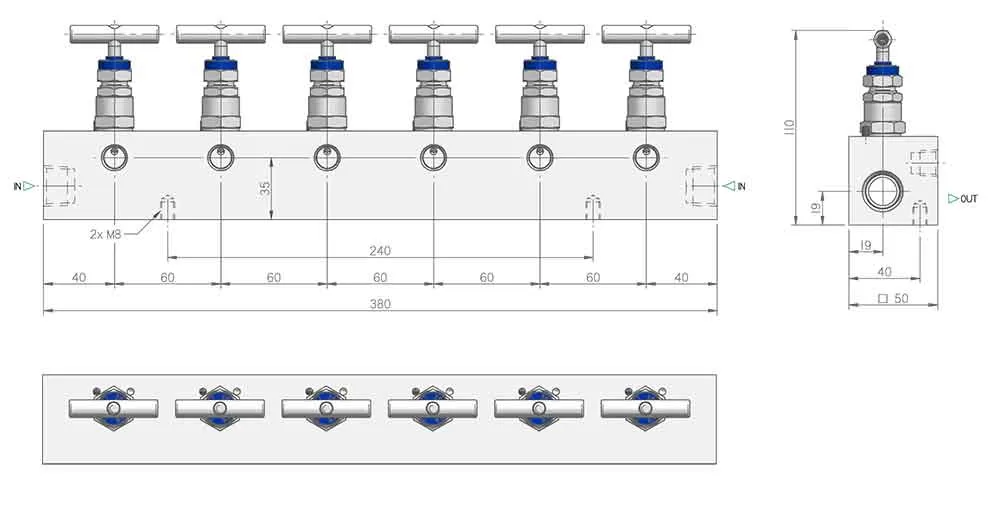

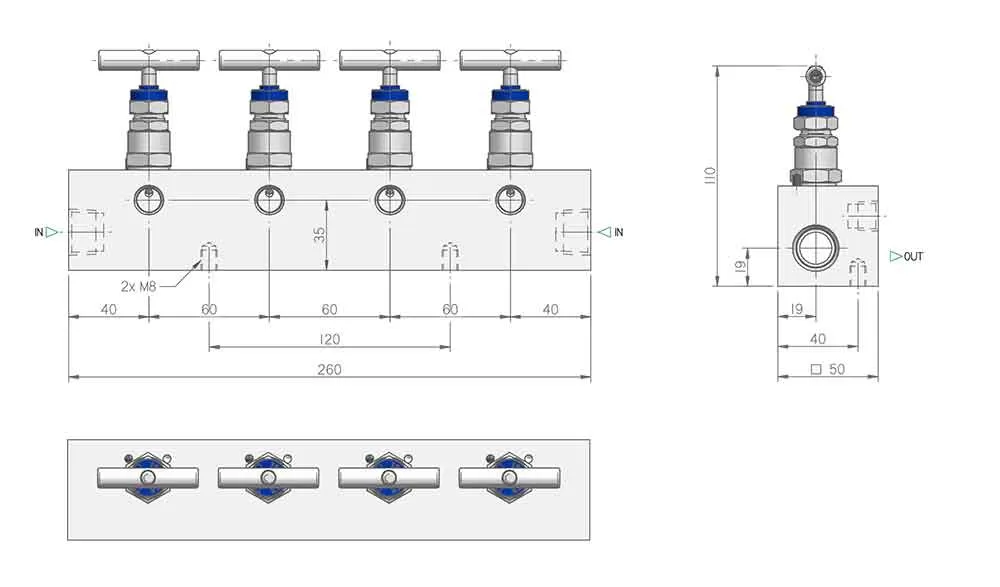

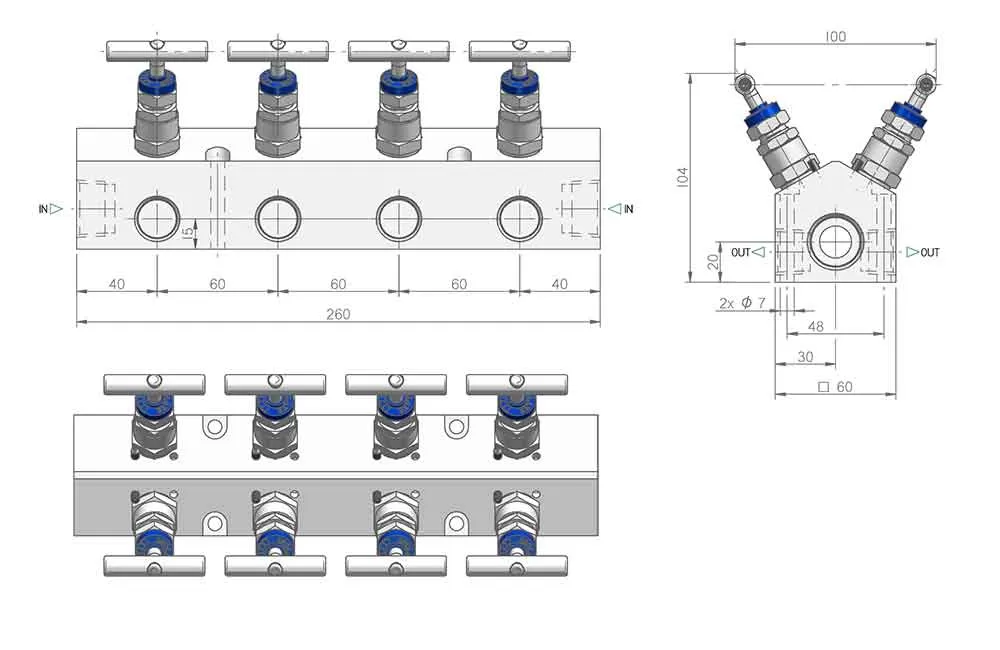

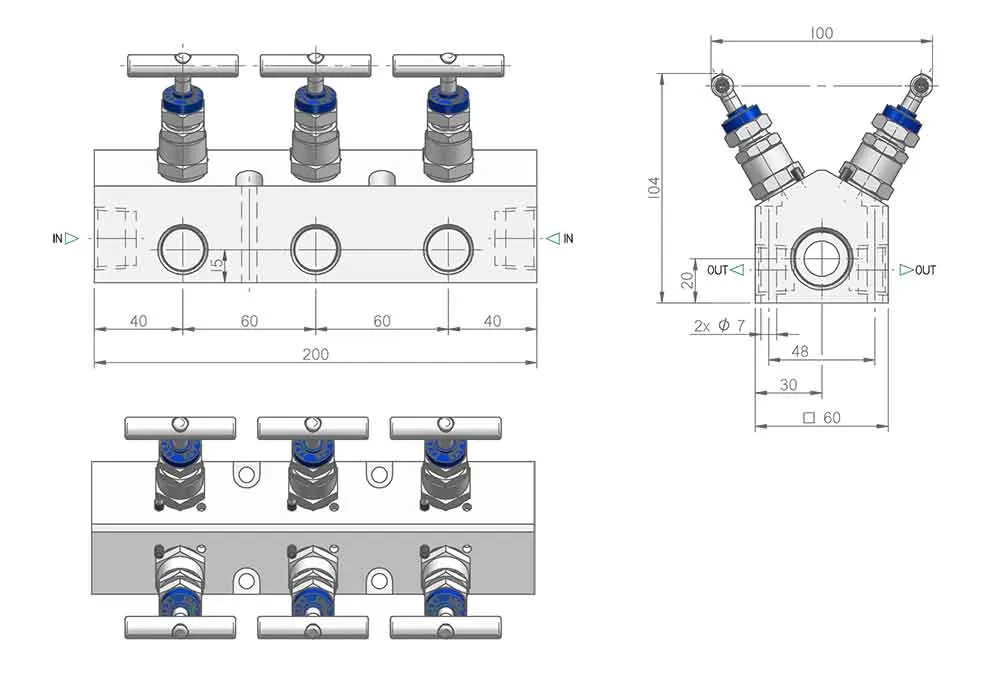

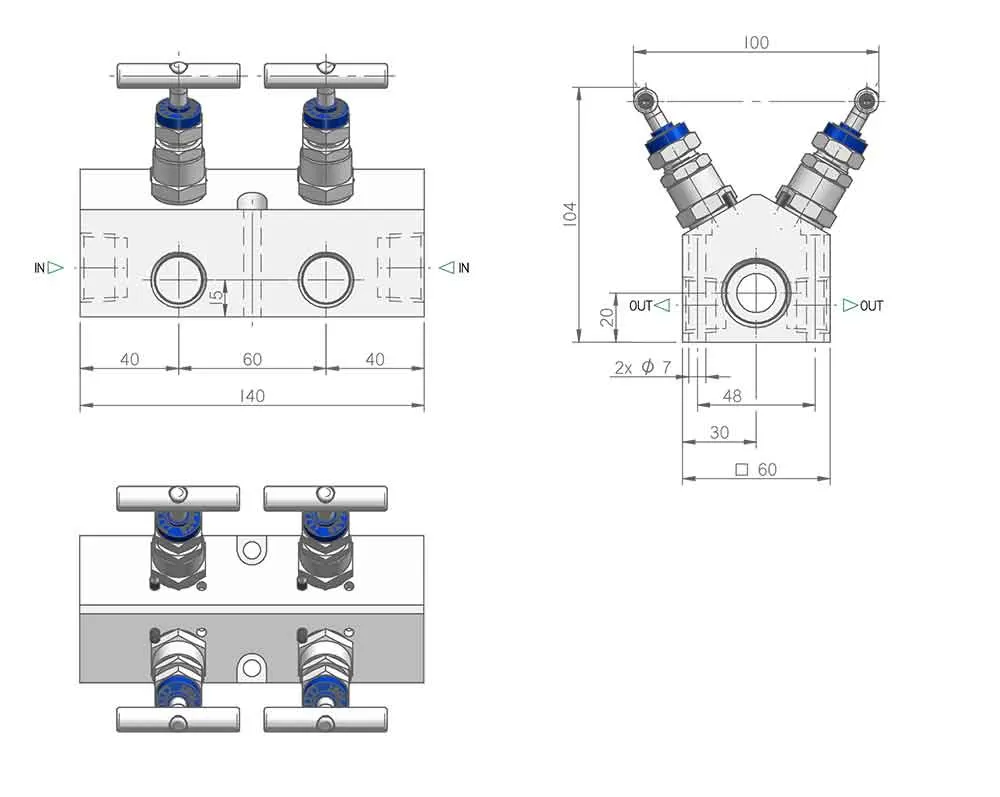

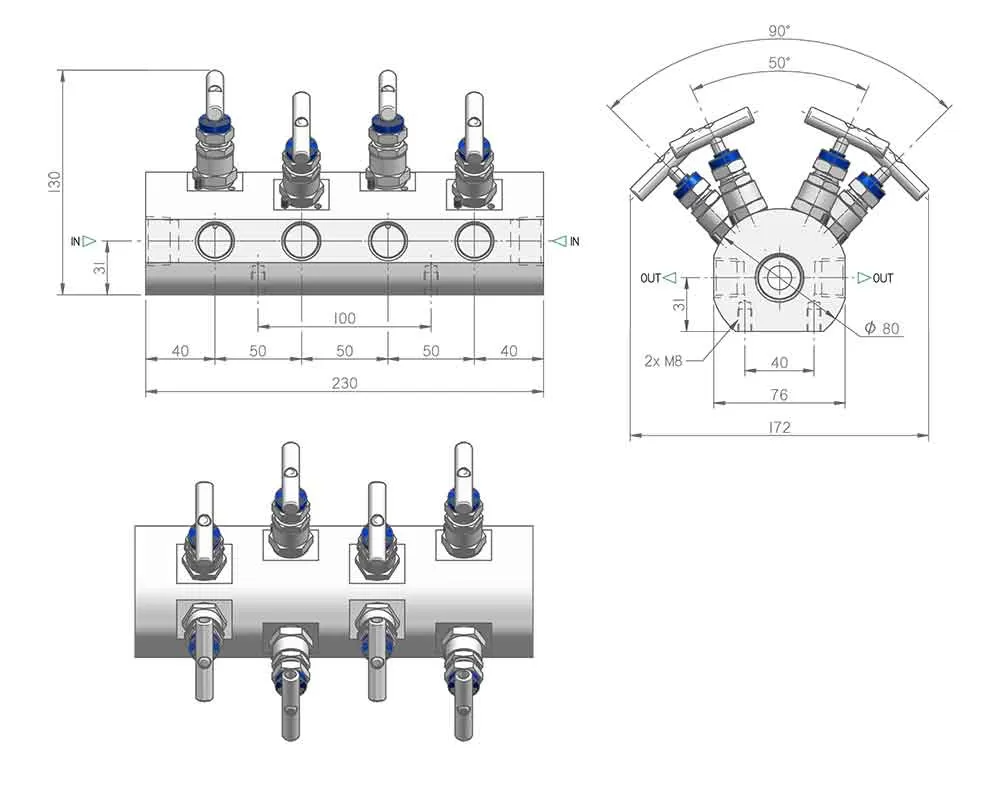

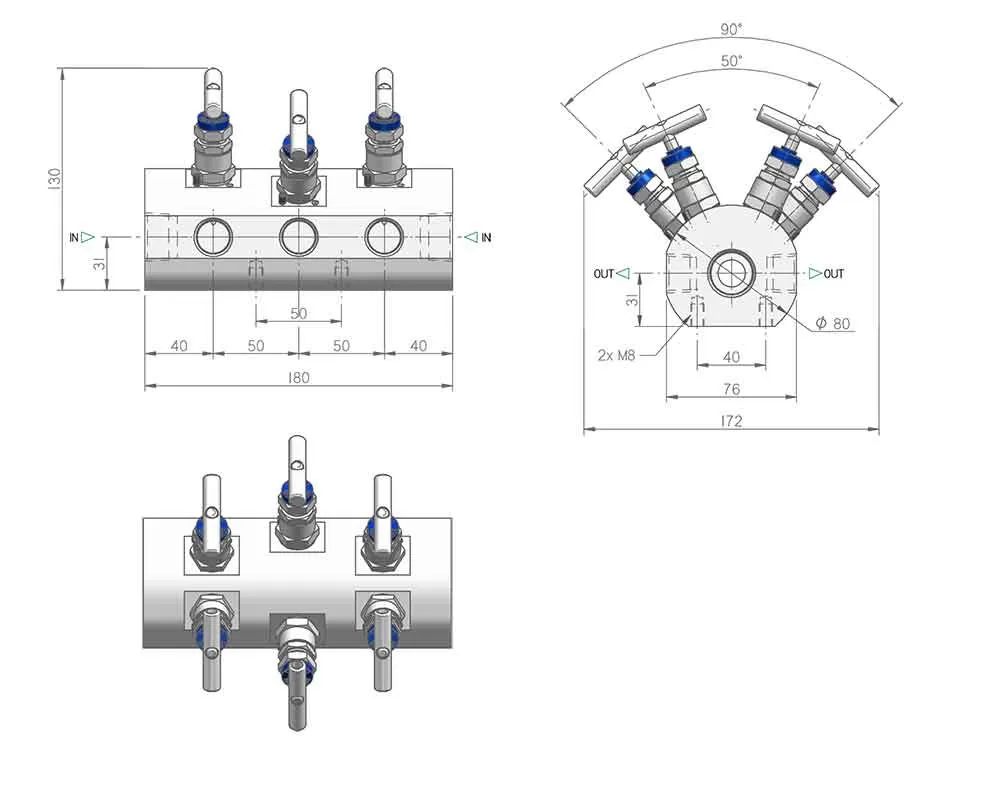

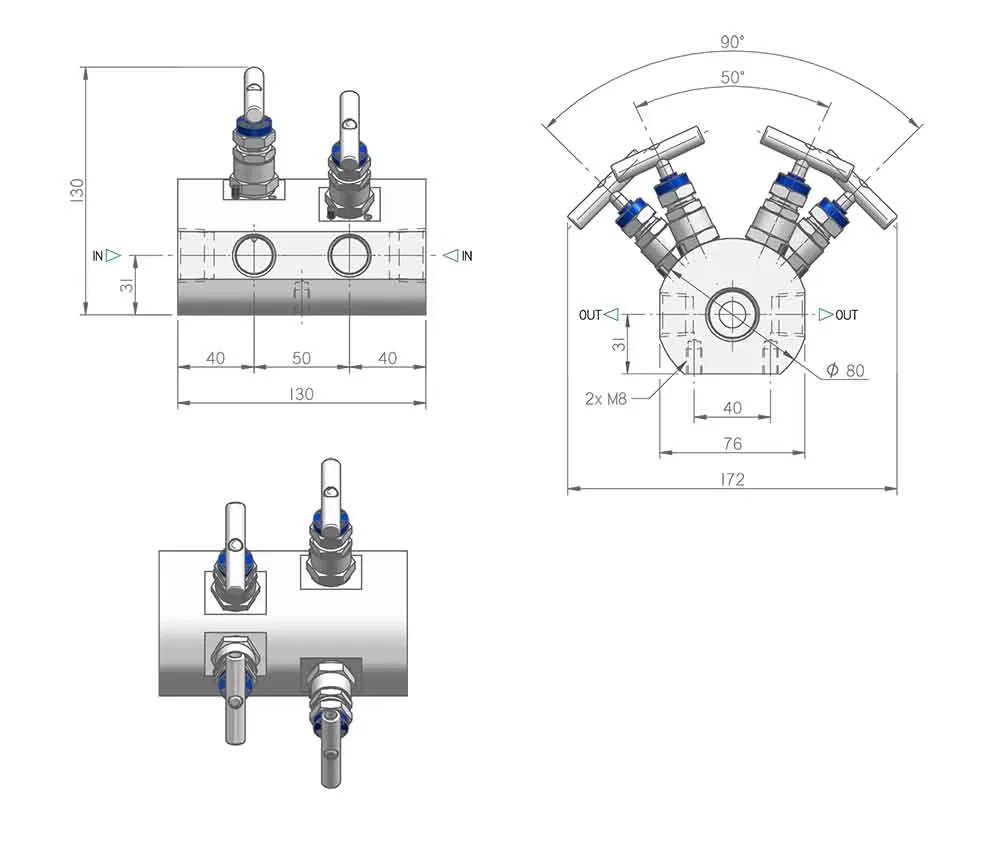

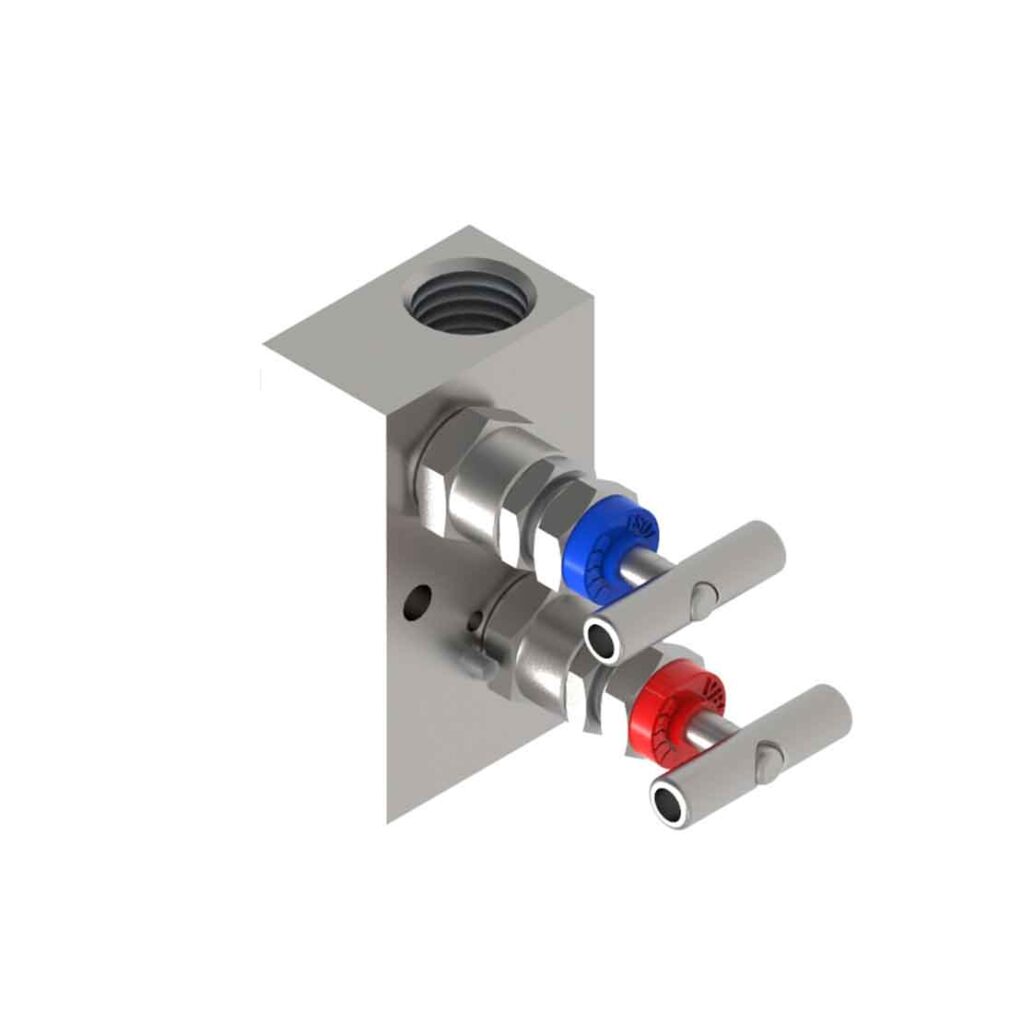

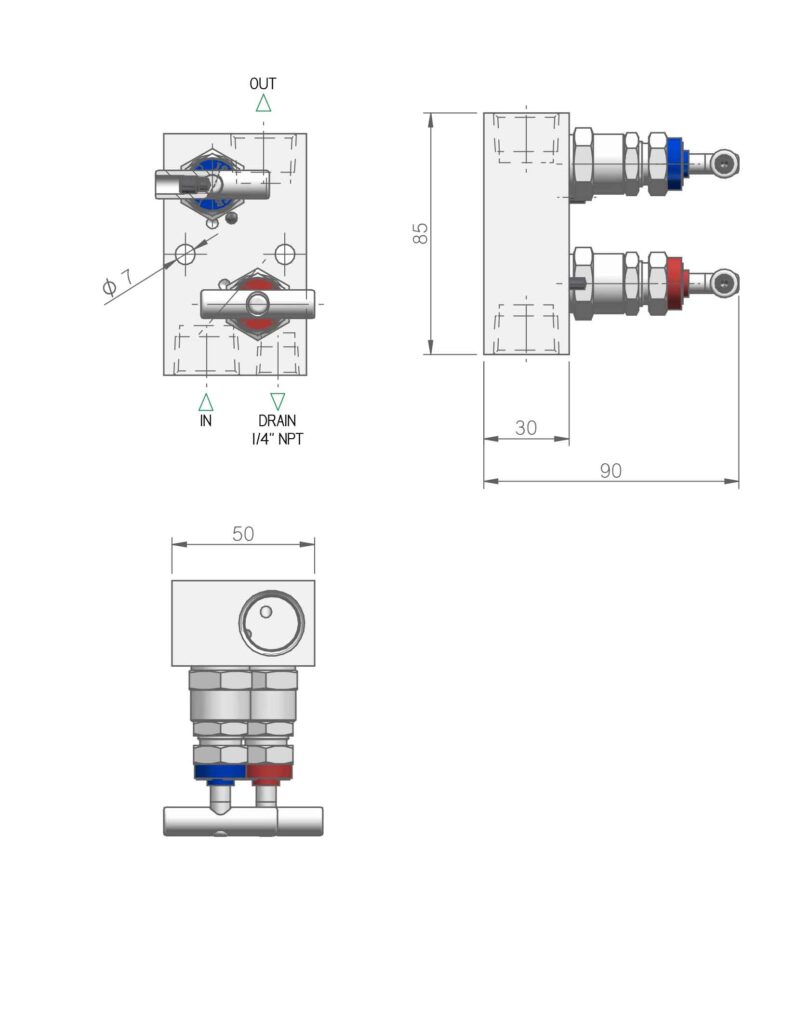

Air Distribution Manifolds (ADM), so called Air Headers.

The purpose of the ADM is to distribute air coming from a central compressor to the different air operated devices on a plant or facility.

The ADM is applied in all kinds of industries, from oil up to food processing.